Method for preparing active phenolic compounds through rosin-induced bioconversion

A technology of compounds and inducers, which is applied in the fields of fine chemical industry and pharmaceutical biology, can solve the problems of low output value and achieve the effects of high selectivity, low cost and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

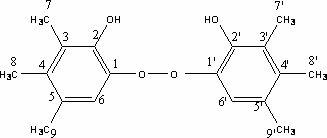

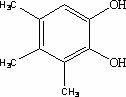

Image

Examples

Embodiment 1

[0034] A. The microbial strain A5+ is routinely cultured in PDA medium to obtain activated strains, and then inserted into PDB medium for fermentation for 48 hours; PDA medium is 200g / L potato + 20g / L glucose + 2% agar, pH The value is 6, autoclaved at 121°C for 15 minutes; PDB medium is 200g / L potato + 20g / L glucose, pH value is 6, autoclaved at 121°C for 15min;

[0035] B. Prepare the inducer of the transformation product; the inducer is to add rosin 0.1g in the PDA medium of every 200mL, 5mL of cosolvent 95% ethanol is sampled, and the solution obtained by fully dissolving rosin in ethanol is the inducer;

[0036] C. Add the inducer prepared in step B to the strain fermented in step A, and react for 96 hours at a temperature of 30° C. and a stirring rate of 120 rpm for biotransformation;

[0037] D. The conversion solution of C is filtered and concentrated to obtain the crude extract of the conversion product;

[0038] E. The crude extract of the conversion product is...

Embodiment 2

[0040] A. The microbial strain A5+ is routinely cultured in PDA medium to obtain activated strains, and then inserted into PDB medium for fermentation for 72 hours; PDA medium is 200g / L potato + 20g / L glucose + 1.5% agar, pH The value is 6, autoclaved at 110°C for 20 minutes; PDB medium is 200g / L potato + 20g / L glucose, pH value is 6, autoclaved at 110°C for 30min;

[0041] B. Prepare the inducer of the transformation product; the inducer is to add rosin 0.2g in the PDA medium of every 200mL, 8mL of cosolvent 95% ethanol is sampled, and the solution obtained by fully dissolving rosin in ethanol is the inducer;

[0042] C. Add the inducer prepared in step B to the strain fermented in step A, and react for 72 hours at a temperature of 26° C. and a stirring rate of 128 rpm for biotransformation;

[0043] D. The conversion solution of C is filtered and concentrated to obtain the crude extract of the conversion product;

[0044] E. The crude extract of the conversion product ...

Embodiment 3

[0046] A. The microbial strain A5+ is routinely cultured in PDA medium to obtain activated strains, and then inserted into PDB medium for fermentation for 60 hours; PDA medium is 200g / L potato + 20g / L glucose + 1.8% agar, pH The value is 6, autoclaved at 125°C for 30 minutes; PDB medium is 200g / L potato + 20g / L glucose, pH value is 6, autoclaved at 125°C for 20min;

[0047] B. Prepare the inducer of the transformation product; the inducer is to add rosin 0.3g in the PDA medium of every 200mL, 6mL of cosolvent 95% ethanol is sampled, and the solution obtained by fully dissolving rosin in ethanol is the inducer;

[0048] C. Add the inducer prepared in step B to the strain fermented in step A, and react for 80 hours at a temperature of 29° C. and a stirring rate of 125 rpm for biotransformation;

[0049] D. The conversion solution of C is filtered and concentrated to obtain the crude extract of the conversion product;

[0050] E. The crude extract of the conversion product ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com