Gallium-nitride-based light emitting diode capable of improving electron injection efficiency

A light-emitting diode and electron injection technology, which is applied in circuits, electrical components, semiconductor devices, etc., can solve problems such as the increase of Fermi energy level and the aggravation of electronic overshoot behavior

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

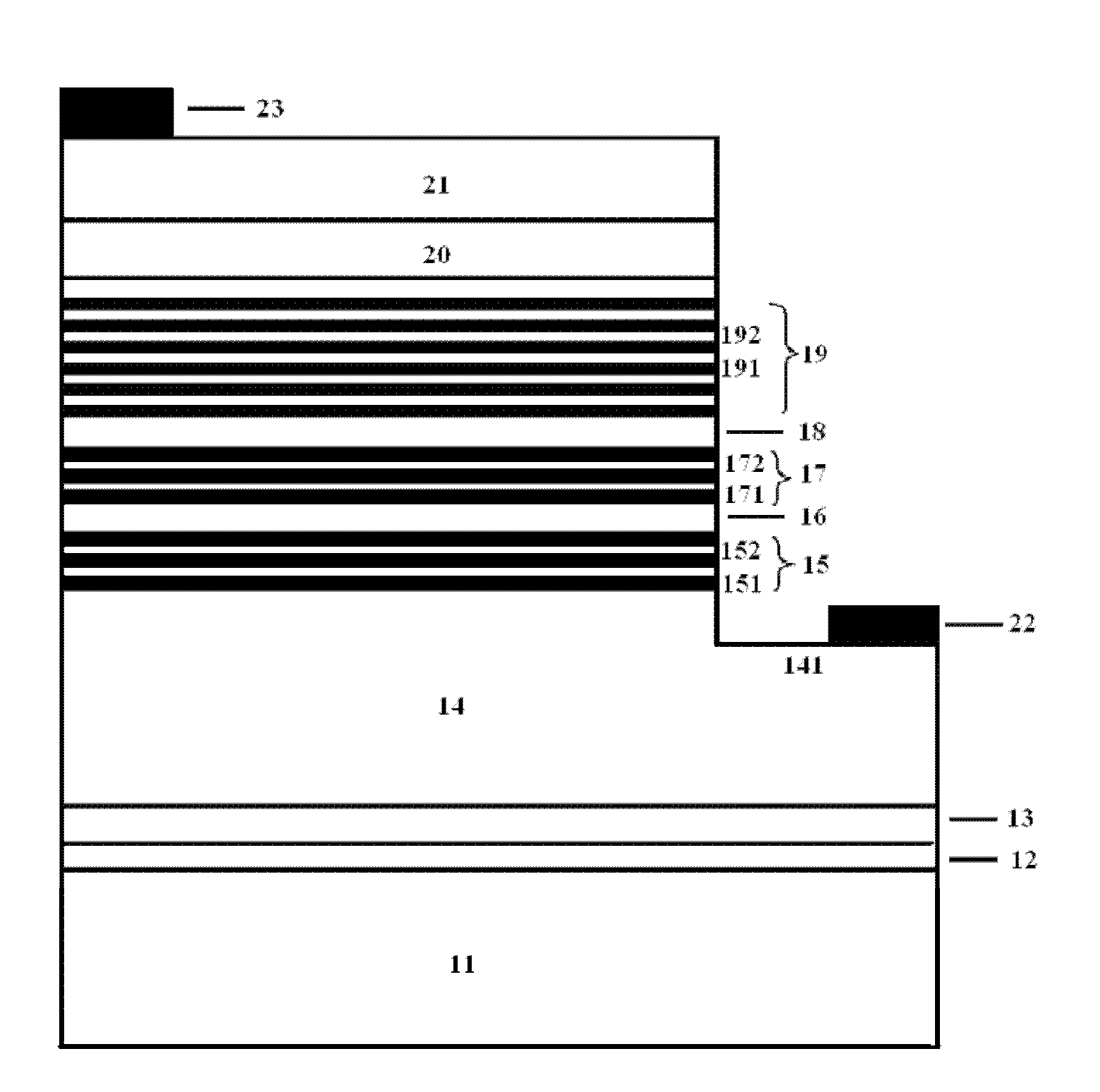

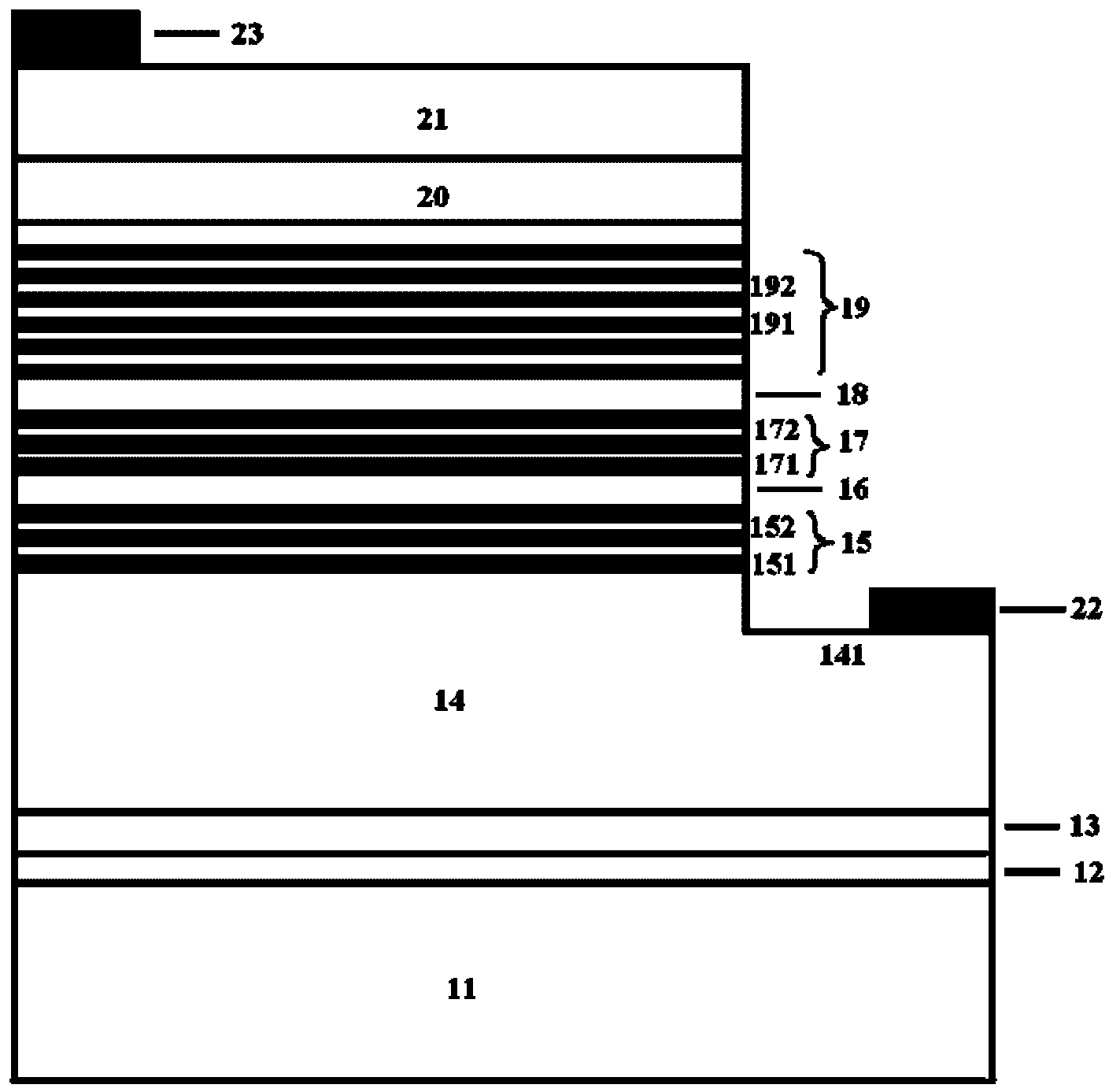

[0023] see figure 1 As shown, the present invention provides a gallium nitride-based light-emitting diode, which includes:

[0024] A substrate 11, from (0001) to sapphire (Al 2 o 3 ) is the substrate 11, and other materials that can be used for the substrate 11 also include aluminum oxide single crystals on the R-plane or A-plane, 6H-SiC, 4H-SiC, or single crystal oxides whose lattice constants are close to those of nitride semiconductors thing. High-purity NH was used in the preparation 3 As N source, high-purity H 2 and N 2 mixed gas as carrier gas; trimethylgallium or triethylgallium as Ga source, trimethylindium as In source, trimethylaluminum as Al source; n-type dopant is silane, p-type dopant is Magnesium dichloride.

[0025] A gallium nitride nucleation layer 12 , the gallium nitride nucleation layer 12 is fabricated on the substrate 11 . Growth parameters include: reaction temperature 500°C to 800°C, reaction chamber pressure 200 to 500 Torr, carrier gas flow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com