Nano ferric phosphate hollow sphere lithium ion battery and preparation method thereof

A lithium-ion battery and nano-iron phosphate technology, applied in the manufacture of electrolyte batteries, battery electrodes, secondary batteries, etc., can solve the problems of poor electronic conductivity, limited electrochemical performance of LiFePO4, low diffusion rate, etc., and achieve good discharge performance , easy to popularize and produce on a large scale, good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

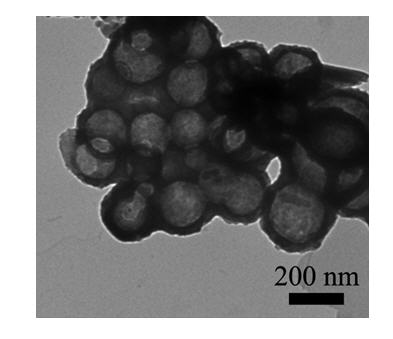

[0033] Take 1.2 g of precipitant urea and 0.1 g of surfactant sodium dodecyl sulfate (SDS) and disperse them in 20 ml of deionized water, and add ferrous ammonium sulfate hexahydrate ((NH 4 ) 2 Fe(SO 4 ) 2 ·6H 2 O) and phosphoric acid (H 3 PO 4 ), the amount of ferrous ammonium sulfate hexahydrate was 0.1 mmol. Place the mixture in an ultrasonic wave for ultrasonic dispersion for 2-10 minutes, and pour it into a stainless steel reaction kettle lined with polytetrafluoroethylene after the dispersion is uniform, close the reaction kettle, place it in an oven and heat it at 60-100 °C for 10 hours, and cool it to room temperature. The product was washed by centrifugation with ethanol and deionized water for 6 times, and the product obtained by centrifugation was placed in an oven at 50-100 °C for 10-24 h in vacuum to obtain nano-iron phosphate hollow spheres with a particle size of about 150-250 nm and an average particle size of The diameter is around 200 nm.

[0034] Accor...

Embodiment 2

[0037] Take 1.2 g urea and 0.1 g SDS and disperse them in 20 ml deionized water, add equimolar (NH 4 ) 2 Fe(SO 4 ) 2 ·6H 2 O and H 3 PO 4 , the amount of substance of ferrous ammonium sulfate hexahydrate was 0.1 mmol. Place the mixture in an ultrasonic wave for ultrasonic dispersion for 2-10 minutes. After the dispersion is uniform, pour it into a stainless steel reaction kettle lined with polytetrafluoroethylene, close the reaction kettle, and heat it in an oven at 60-100 °C for 12 hours, then cool it down. to room temperature. The product was centrifuged and washed with ethanol and deionized water for 8 times, and the product obtained by centrifugation was placed in an oven at 50-100 ℃ for 10-24 h in vacuum to obtain nano-iron phosphate hollow spheres with a particle size of about 150-250 nm, with an average The particle size is around 200 nm.

[0038] The preparation process of the lithium-ion battery is exactly the same as in Example 1. When the charging current de...

Embodiment 3

[0040] Take 0.6 g urea and 0.05 g SDS and disperse them in 20 ml deionized water, add (NH 4 ) 2 Fe(SO 4 ) 2 ·6H 2 O and H 3 PO 4 , the amount of the substance of ferrous ammonium sulfate hexahydrate is 0.05 mmol. Place the mixture in an ultrasonic wave for ultrasonic dispersion for 2-10 minutes. After the dispersion is uniform, pour it into a stainless steel reaction kettle lined with polytetrafluoroethylene, close the reaction kettle, and heat it in an oven at 60-100 °C for 3-12 hours. , cooled to room temperature. Wash the product by centrifugation with ethanol and deionized water for 3-8 times respectively, and place the product obtained by centrifugation in an oven at 50-100 ℃ for 10-24 h in vacuum to obtain nano-iron phosphate hollow spheres with a particle size of about 200-300 nm , with an average particle size of about 250 nm.

[0041] The preparation process of the lithium-ion battery is exactly the same as in Example 1. When the charging current density of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com