Ternary core-shell composite photocatalyst and preparation method thereof

A catalyst, core-shell type technology, applied in the field of photocatalysis, can solve the problems of poor resistance to photochemical corrosion, low utilization rate of sunlight, intolerance to high-energy photons, etc. Effect of Catalytic Degradation of Dyestuff Wastewater

- Summary

- Abstract

- Description

- Claims

- Application Information

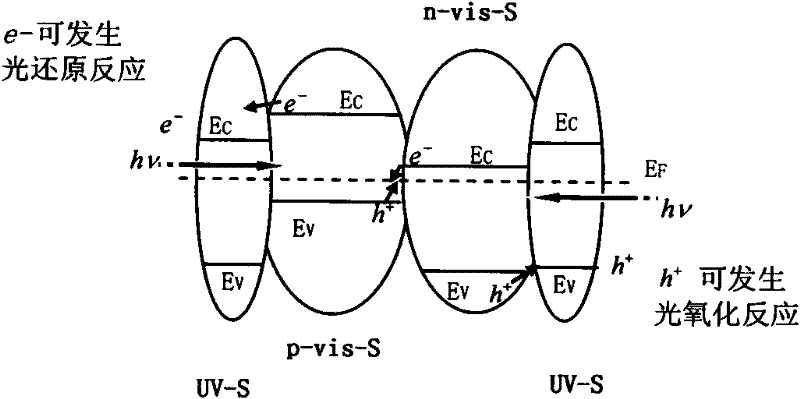

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

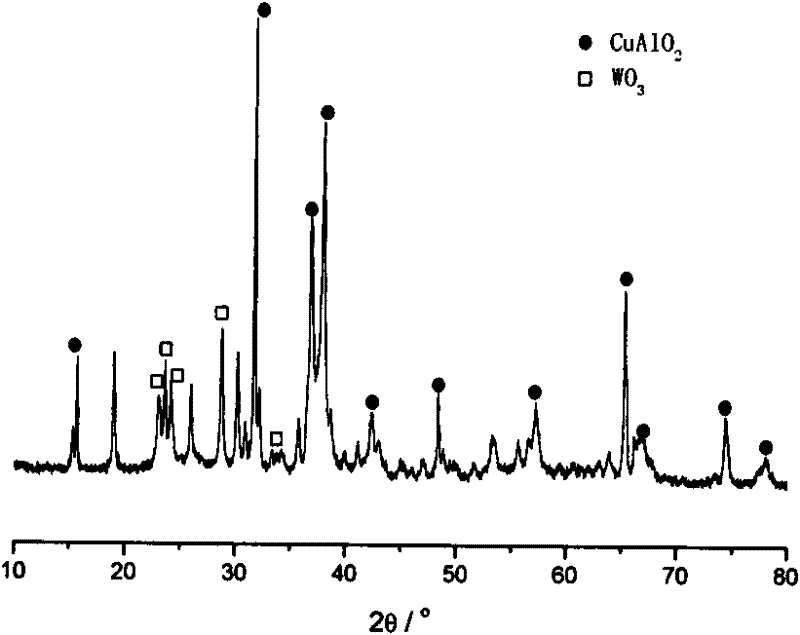

[0025] TiO 2 / WO 3 -CuAlO 2 preparation of

[0026] (1) Semi-wet synthesis of CuAlO 2 :

[0027] Weigh 5g Cu(NO 3 ) 2 ·3H 2 O, and Al(NO 3 )·9H 2 O, 7.7g, was dissolved in deionized water respectively to obtain a copper nitrate solution and an aluminum nitrate solution with a mass percentage composition of 20%, and then the oxalic acid solution with a mass concentration of 25% was added to the copper nitrate solution to form a copper oxalate precipitation, The molar ratio of oxalic acid to copper is 1.2:1, and the resulting precipitate is filtered, washed, mixed with aluminum nitrate solution, and evaporated to dryness in a water bath at 80°C with continuous stirring. The evaporated solid was calcined at 1000°C for 6h in a nitrogen atmosphere to obtain CuAlO 2 . Pass through a 300-mesh sieve after grinding;

[0028] (2) Synthesis of WO by precipitation loading method 3 -CuAlO 2 :

[0029] Take 2g of CuAlO prepared by (1) 2, its molar number is 0.0163mol, weighs...

Embodiment 2

[0037] TiO 2 / WO 3 -CuAlO 2 Photocatalytic water splitting performance test

[0038] (1) Using photodeposition method on TiO 2 / WO 3 -CuAlO 2 Surface load Pt:

[0039] H 2 PtCl 6 Dissolve in dehydrated ethanol solution, make the solution that the mass concentration is 1% in terms of Pt, then the TiO obtained in Example 1 2 / WO 3 -CuAlO 2 Place the powder in it, irradiate it with a 250W halogen tungsten lamp for 0.5h while magnetically stirring, then filter, and dry at 120°C to obtain a catalyst for photocatalytic water splitting to produce hydrogen;

[0040] Among them, Pt and TiO 2 / WO 3 -CuAlO 2 The mass percent of = 0.2%.

[0041] (2) Performance test of the catalyst for photocatalytic water splitting to produce hydrogen.

[0042] Take 0.5g of the above TiO loaded with Pt 2 / WO 3 -CuAlO 2 Photocatalyst, put in 1000mL quartz glass reactor, add 800mL deionized water and 0.5g anhydrous Na 2 CO 3 (Make solution pH = 11). Then connect the reactor into a clos...

Embodiment 3

[0048] TiO 2 / WO 3 -CuAlO 2 Performance test of photocatalytic degradation of acid red B

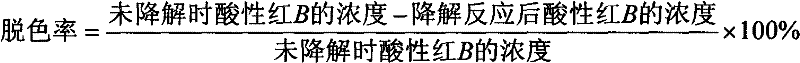

[0049] Get the TiO that embodiment 1 makes 2 / WO 3 -CuAlO 2 Catalyst 0.1g, put in 800mL beaker, add 600mL acid red B solution with a concentration of 10mg / L, stir magnetically for 0.5h in a dark state, take a sample, measure the concentration of acid red B with a spectrophotometer, and use it as the acid red B solution when it is not degraded. For the concentration of red B, after irradiating with a 300W xenon lamp for 1 hour, measure the concentration of acid red B, which is the concentration of acid red B after degradation, and use the following formula to calculate the decolorization rate of acid red B.

[0050]

[0051] The result is: TiO 2 / WO 3 -CuAlO 2 Under the action of the catalyst, after 1 hour, the decolorization rate of Acid Red B was 95.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com