Preparation method of microbial cellulose

A technology of microbial cellulose and seeds, applied in the directions of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of high price, limited application and high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

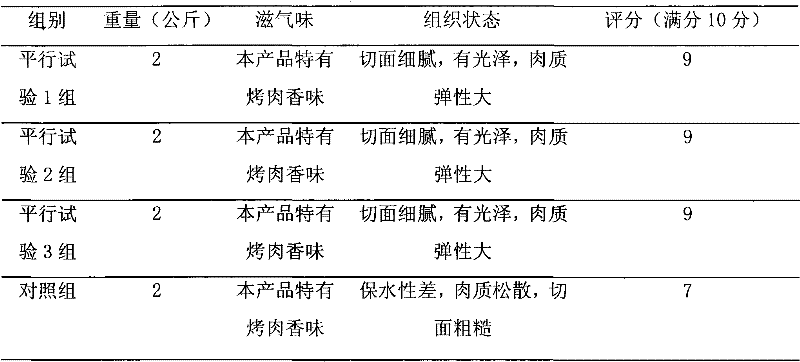

Examples

Embodiment Construction

[0016] Below in conjunction with specific embodiment the present invention is described in more detail:

[0017] 1.1. Source of fermentation strain

[0018] The number of Acetobacter aceti in this example is CICC21682 Acetobacter aceti, which was purchased from China Industrial Microorganism Culture Collection and Management Center.

[0019] 1.2 Strain mutagenesis

[0020] First, Acetobacter aceticum was made into bacterial suspension, and irradiated with a 15W ultraviolet lamp at a distance of 30cm for 20 seconds, stirring while irradiating, trying to make the bacteria absorb ultraviolet light waves evenly. The above irradiation process was carried out in a dark room to avoid photorepair. Transfer the bacteria after ultraviolet mutagenesis into a sterile test tube and immediately immerse in ice water for 1 hour. Under low temperature conditions, the activities of various enzymes involved in the repair of mutants in the cells are inhibited, making the repair difficult. It is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com