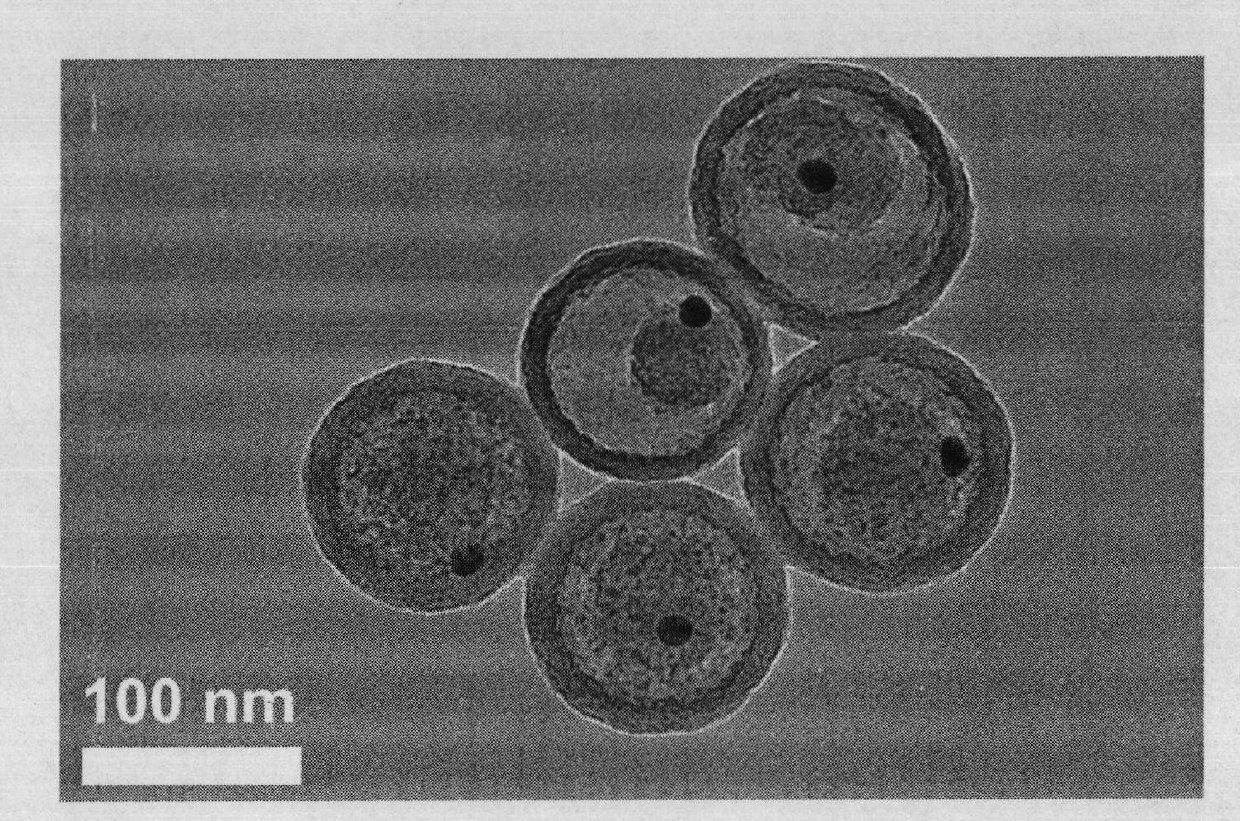

Hollow silicon dioxide sub-microsphere with nanoscale precious metal and silicon dioxide kernel and preparation method thereof

A silica ball and silica technology, which is applied in the preparation of organic compounds, metal/metal oxide/metal hydroxide catalysts, nanostructure manufacturing, etc. problems, to achieve the effect of simple operation, easy industrialized large-scale production, and preventing agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Hollow silica submicron spheres with silica cores can be prepared with reference to patent application number 200610089184.9:

[0030] Step 1: Prepare hybrid silica submicron spheres by sol-gel method.

[0031] Prepare 160 parts by volume of ammonia water mixed solution with a mixed solvent of methanol and acetonitrile (volume ratio is 1: 1), so that the molar concentration of ammonia water in the mixed solution is 1.2mol / L; prepare 25 parts by volume of methanol solution of methyl orthosilicate , so that the molar concentration of methyl orthosilicate in methanol solution of methyl orthosilicate is 0.05mol / L; prepare 10 parts by volume of methanol solution of trimethoxysilylpropyl ethylenediamine, make trimethoxysilylpropylethylenediamine The molar concentration of the amine in the methanol solution of trimethoxysilylpropylethylenediamine is 1×10 -3 mol / L; based on the volume of methanol solution of methyl orthosilicate.

[0032] Add 12 parts by volume of methanol so...

Embodiment 2

[0046] Hollow silica submicron spheres with silica cores can be prepared with reference to patent application number 200610089184.9:

[0047] Step 1: Prepare hybrid silica submicron spheres by sol-gel method.

[0048] Prepare 200 parts by volume of ammonia water mixed solution with the mixed solvent of acetone and propanol (volume ratio is 2: 1), make the molar concentration of ammonia water in the mixed solution be 6.5mol / L; Prepare orthosilicate ethyl ester and orthopropyl silicate 40 parts by volume of propanol mixed solution, so that the molar concentration of ethyl orthosilicate and propyl orthosilicate in the propanol mixed solution of ethyl orthosilicate and propyl orthosilicate respectively is 1.8mol / L; prepare aniline 20 parts by volume of the propanol solution of methyltriethoxysilane, so that the molar concentration of anilinomethyltriethoxysilane in the propanol solution of anilinomethyltriethoxysilane is 1.5×10-3mol / L; The volume part of the propanol mixed soluti...

Embodiment 3

[0057] Hollow silica submicron spheres with silica cores can be prepared with reference to patent application number 200610089184.9:

[0058]Step 1: Prepare hybrid silica submicron spheres by sol-gel method.

[0059] Prepare 80 parts by volume of ethanol solution of ammonia water, so that the molar concentration of ammonia water in the ethanol solution of ammonia water is 0.05mol / L; prepare 20 parts by volume of ethanol solution of ethyl orthosilicate, make ethyl orthosilicate The molar concentration in the ethanol solution of ester is 0.1mol / L; Prepare 5 parts by volume of ethanol solution of trimethoxysilylpropylethylenediamine, make trimethoxysilylpropylethylenediamine in the ethanol of trimethoxysilylpropylethylenediamine The molar concentration in the solution is 7×10 -4 mol / L; based on the parts by volume of the ethanol solution of ethyl orthosilicate.

[0060] Add 5 parts by volume of ethanol solution of tetraethyl orthosilicate dropwise to the ethanol solution of amm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com