Gradient hydrogen process grown ZnO-TCO thin film with textured structure and use thereof

A hydrogen and textured technology, which is applied in the field of growing textured ZnO-TCO films by the gradient hydrogen method, can solve the problems of film grain size reduction, film compressive stress increase, film resistivity increase, etc., to improve efficiency and The effects of stability, good electrical characteristics, and good transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1. Using magnetron sputtering technology, ZnO:Ga with a purity of 99.995% 2 o 3 The ceramic target is used as the target material, and the dopant component Ga in the ceramic target 2 o 3 The weight percentage is 1.0%, the sputtering gas is Ar gas, and the textured structure ZnO-TCO film is grown on the glass substrate, the substrate temperature is 125 ℃, and the background vacuum is 8×10 -5 Pa, the sputtering pressure is 4.3mTorr, and the sputtering power density is 1.0W / cm 2 , film thickness is 1200nm. The film structure is: glass / Ga-doped ZnO-TCO film grown under the condition of "lower hydrogen flow + normal hydrogen flow" with gradient hydrogen flow rate. cycle, the normal hydrogen flow rate of 6.0sccm is 15 cycles.

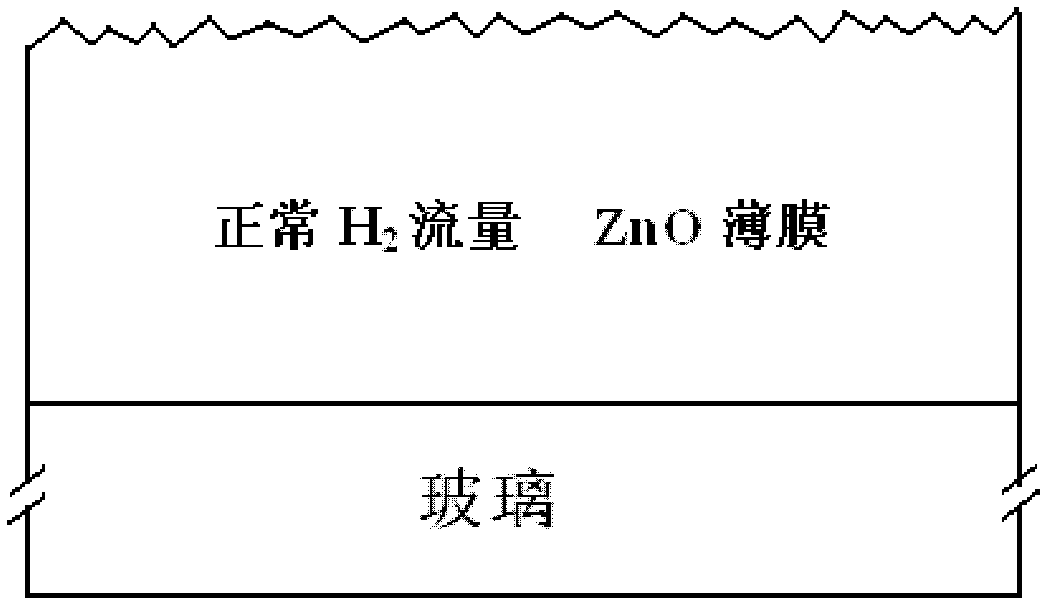

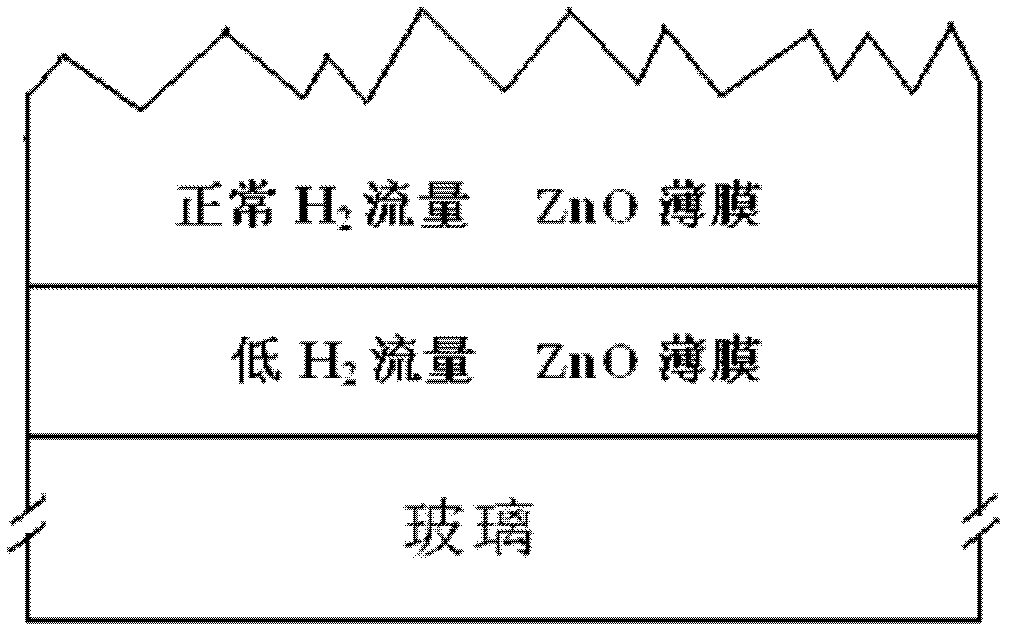

[0026] figure 2 It is a schematic diagram of the structure of the textured ZnO thin film, and figure 1 Compared with the textured ZnO film structure obtained under the normal hydrogen flow rate, the film obtained by the gradient change of the h...

Embodiment 2

[0029] Using magnetron sputtering technology, ZnO:Al with a purity of 99.995% 2 o 3 The ceramic target is used as the target raw material, and the dopant component Al in the ceramic target 2 o 3 The weight percentage is 1.0%, the sputtering gas is Ar gas, and the ZnO-TCO thin film is grown on the glass substrate, the substrate temperature is 250 ℃, and the background vacuum is 8×10 -5 Pa, the sputtering pressure is 4.0mTorr, and the sputtering power density is 0.8W / cm 2 , film thickness is 1500nm. The film structure is: Al-doped textured ZnO-TCO film grown under the condition of glass / gradient hydrogen flow rate as "lower hydrogen flow + normal hydrogen flow", and the total number of coating times is 20 cycles, of which the lower hydrogen flow 1 sccm is 5 cycles, normal oxygen flow 4.5 sccm is 15 cycles.

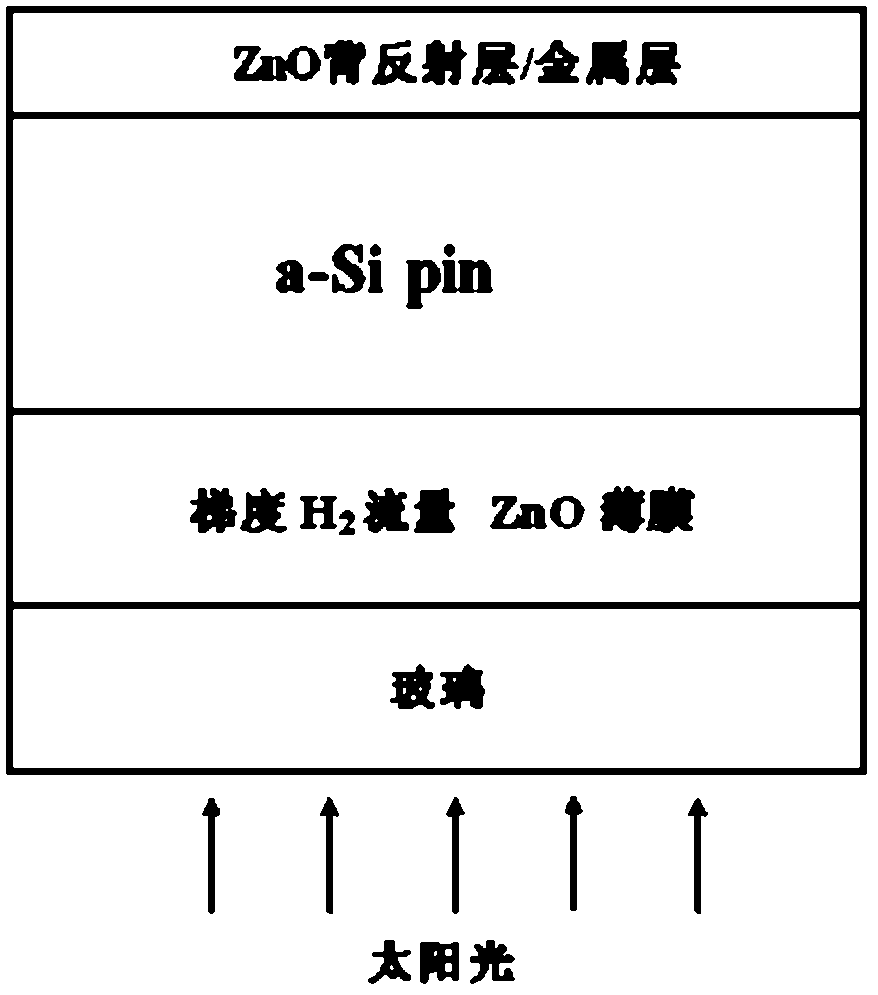

[0030] 2. Apply the above textured ZnO-TCO thin film to pin type a-Si thin film solar cells. like image 3 As shown, the textured ZnO film is plated on the glass subs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com