Composite conductive fiber with coaxial three-element, and preparation method thereof.

A composite conductive and binary composite technology, which is applied in fiber processing, fiber type, textiles and papermaking, etc., can solve the problems of difficulty in blending spinning process, degradation of fiber mechanical properties, high addition of conductive polymer particles, etc., and achieve equipment investment Low cost, simple preparation process, good conductive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

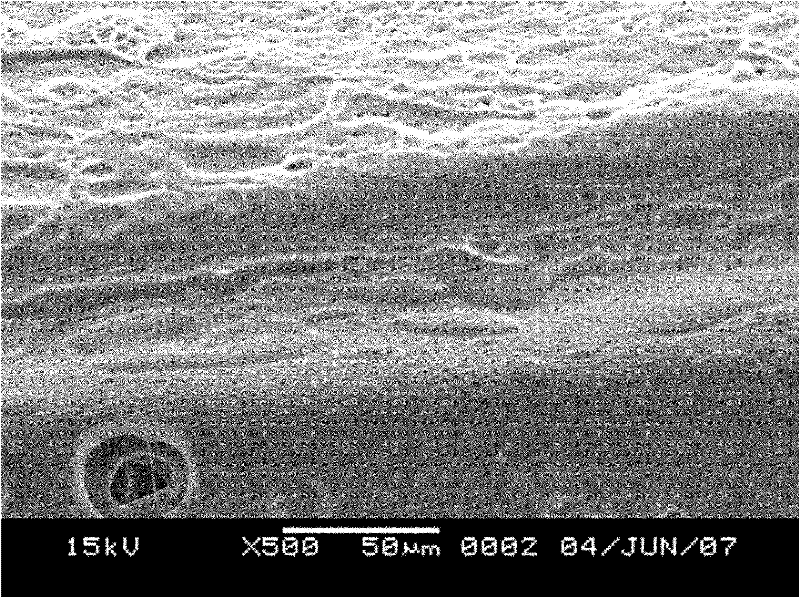

[0030] Polyurethane fibers were treated in ether for 5 minutes and dried, and this polyurethane fibers were treated in tetrahydrofuran treatment solution containing carbon nanotubes (single-walled carbon nanotubes, diameter 0.4nm, length 1 μm) for 1 minute; treated fibers Soak in aniline hydrochloric acid solution (hydrochloric acid concentration: 1M) for 1 hour, the concentration of aniline is 0.1mol / L; then add ammonium persulfate hydrochloric acid solution (concentration of ammonium persulfate is 0.1mol / L) dropwise 0.5ml / min, the system was reacted in an ice-water bath for 5h, and then continued to react at 2°C for 5h, and the fiber was taken out and cleaned to obtain a polyaniline / carbon nanotube / polyurethane ternary composite fiber, wherein the weight of each component was The ratio is 1 part of polyaniline, 1 part of carbon nanotube, and 98 parts of polyurethane; the electrical conductivity of the polyaniline / carbon nanotube / polyurethane ternary composite fiber is 10 -4 ...

Embodiment 2

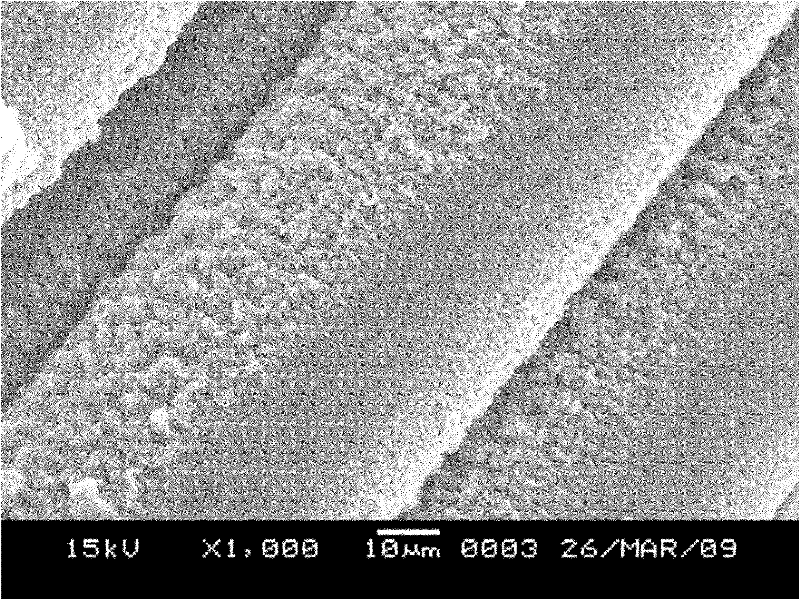

[0032]The polyurethane fiber was treated in ether for 30 minutes and dried, and the polyurethane fiber was treated for 10 minutes in the dimethyl sulfoxide treatment liquid containing carbon nanotubes (multi-walled carbon nanotubes, diameter 60nm, length 15 μm); The fibers were soaked in aniline hydrochloric acid solution (hydrochloric acid concentration: 1M) for 2 hours, and the aniline concentration was 1mol / L; then ammonium persulfate hydrochloric acid solution (ammonium persulfate concentration: 1.25mol / L) was added dropwise The acceleration is 1ml / min. After the system is reacted in an ice-water bath for 6 hours, the reaction is continued at 4°C for 4 hours. The fiber is taken out and cleaned to obtain a polyaniline / carbon nanotube / polyurethane ternary composite fiber, wherein the weight of each component is The ratio is 20 parts of polyaniline, 10 parts of carbon nanotubes, and 70 parts of polyurethane; the electrical conductivity of the polyaniline / carbon nanotube / polyur...

Embodiment 3

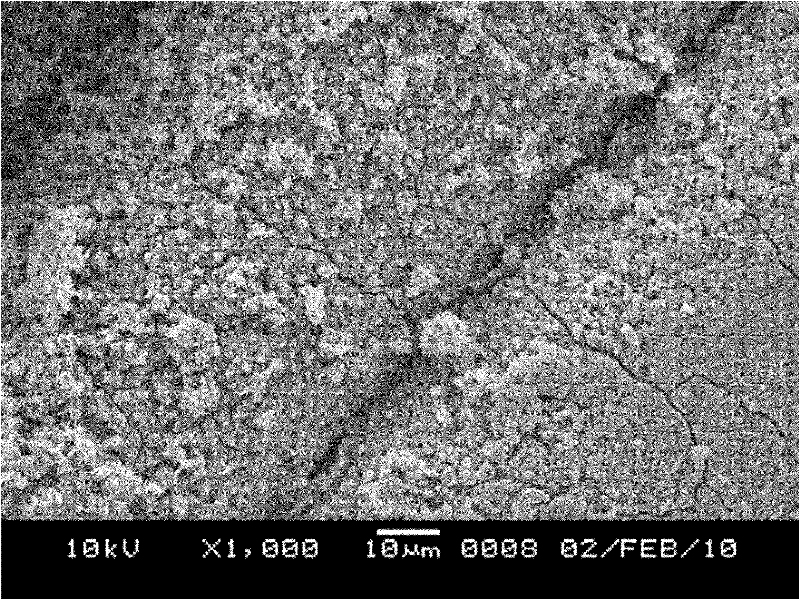

[0034] The polyurethane fibers were treated in ether for 5 minutes successively, and dried, and the polyurethane fibers were treated in the dimethylacetamide treatment liquid containing carbon nanotubes (single-walled carbon nanotubes, 20 nm in diameter, and 5 μm in length) for 1 minute; The treated fiber is immersed in pyrrole sodium chloride solution (sodium chloride solution concentration is 0.3M) for 1h, and the pyrrole concentration is 0.1mol / L; then ferric trichloride sodium chloride solution is added dropwise to the solution (Concentration of ferric chloride is 0.2mol / L), and the addition rate is 1.5ml / min. After the system reacts in an ice-water bath for 7 hours, it continues to react for 3 hours at 10°C, and the fibers are taken out and cleaned to obtain polypyrrole carbon nanotubes. / polyurethane ternary composite fiber, wherein the weight ratio of each component is 5 parts of polypyrrole, 5 parts of carbon nanotubes, and 80 parts of polyurethane; the electrical condu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com