Novel N-type silicon hetero-junction battery with IBC (interdigitated back-contacted) structure and fabrication method thereof

A silicon heterojunction, N-type technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as battery decline, battery efficiency limitation, and improvement, and achieve the goal of increasing short-circuit current density, improving stability, and reducing damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

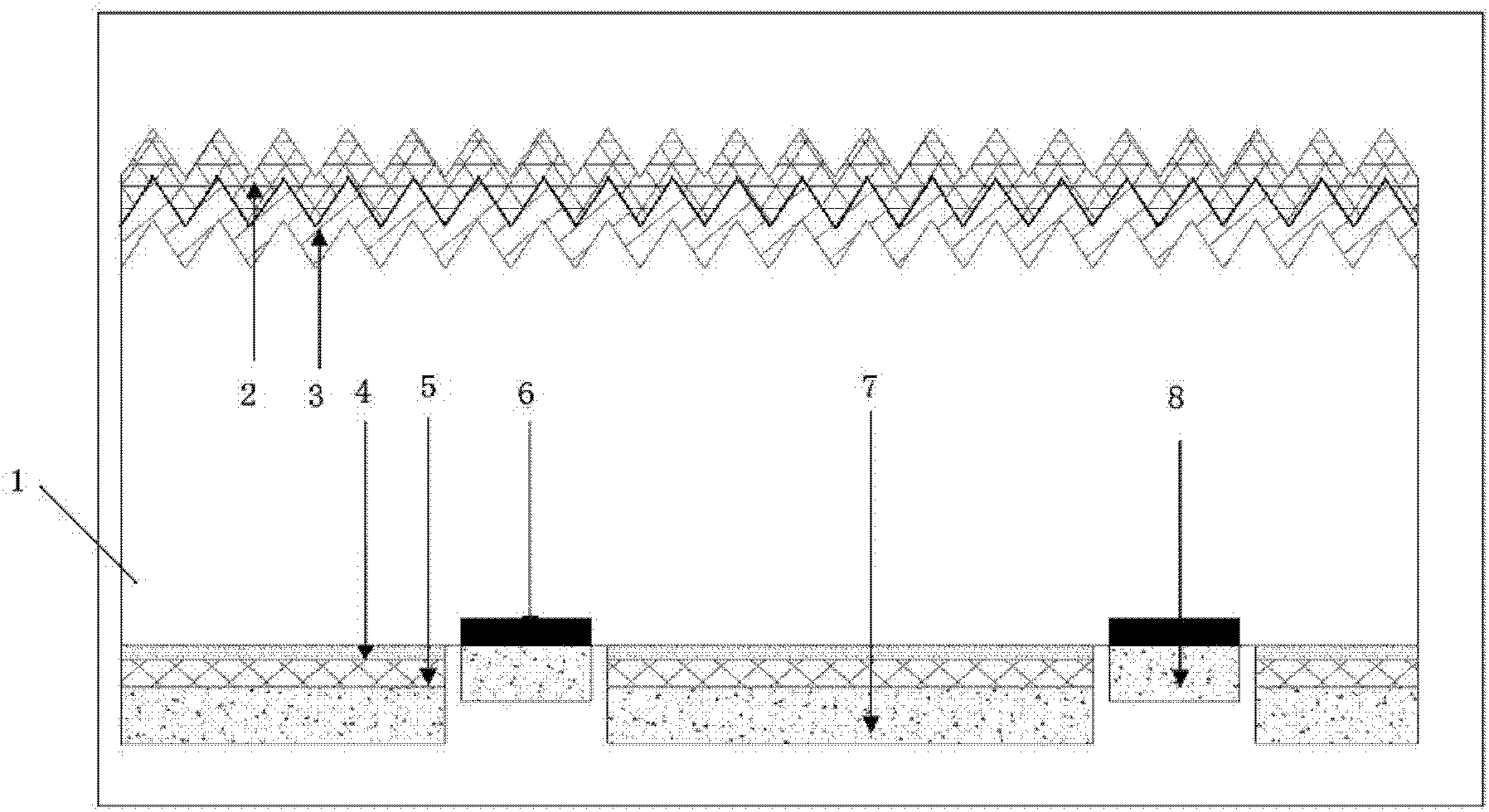

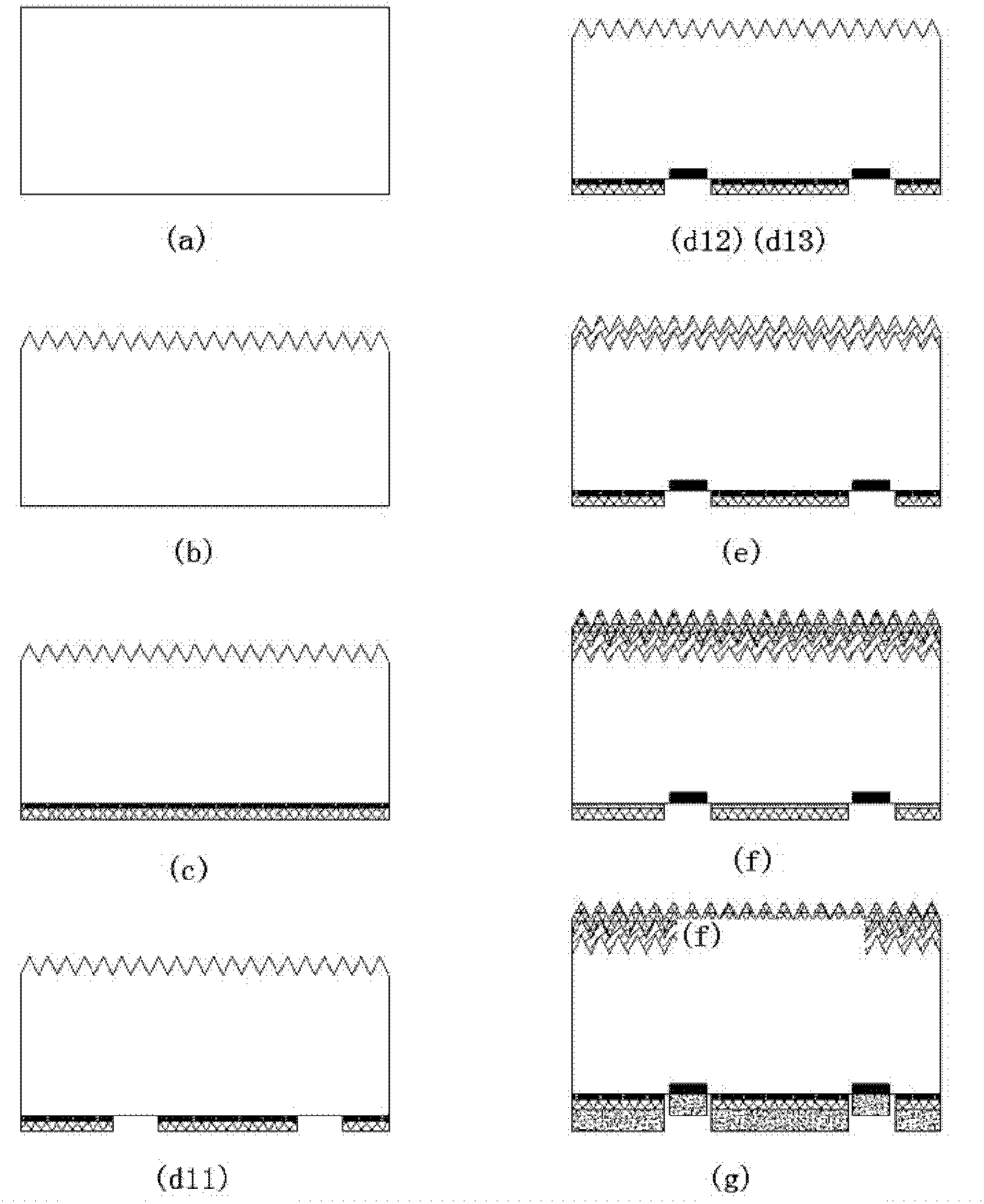

[0045] Such as figure 1A new IBC structure N-type silicon heterojunction cell is shown, including: N-type silicon substrate 1, silicon nitride film 2, aluminum oxide film 3, intrinsic amorphous silicon 4, and P-type amorphous silicon 5. N-type heavily doped region 6, positive electrode 7 of the battery, negative electrode 8 of the battery; the front surface of the N-type silicon substrate 1 is covered with an aluminum oxide film 3, and the aluminum oxide layer film 3 is covered with a nitride Silicon thin film 2; intrinsic amorphous silicon 4 and P-type amorphous silicon 5 are deposited on the back surface of the N-type silicon substrate 1, and intrinsic amorphous silicon 4 and P-type amorphous silicon 5 are provided with grooves. The bottom of the groove is an N-type heavily doped region 6, and the electrode negative electrode 8 is arranged in the groove; the positive electrode 7 of the battery is arranged on the back surface of the P-type amorphous silicon 5.

[0046] The p...

Embodiment 2

[0061] The structure of the new type IBC structure N-type silicon heterojunction cell is the same as in Example 1;

[0062] The preparation method of the novel IBC structure N-type silicon heterojunction cell in Example 2 is as follows:

[0063] (a) Select an N-type silicon substrate, and the resistivity of the N-type silicon substrate is 5??cm;

[0064] (b) Use potassium hydroxide solution to texture the surface of the N-type single crystal silicon substrate, prepare a pyramid-shaped light-trapping structure on the surface of the N-type silicon substrate, and perform chemical cleaning with a mixed solution of hydrochloric acid and hydrofluoric acid The concentration of potassium hydroxide solution is 1.5%; in the mixed solution of hydrochloric acid and hydrofluoric acid, the ratio of hydrochloric acid to hydrofluoric acid is 1:2; the concentration of mixed solution of hydrochloric acid and hydrofluoric acid is 0.9%;

[0065] (c) Deposit intrinsic amorphous silicon and P-type...

Embodiment 3

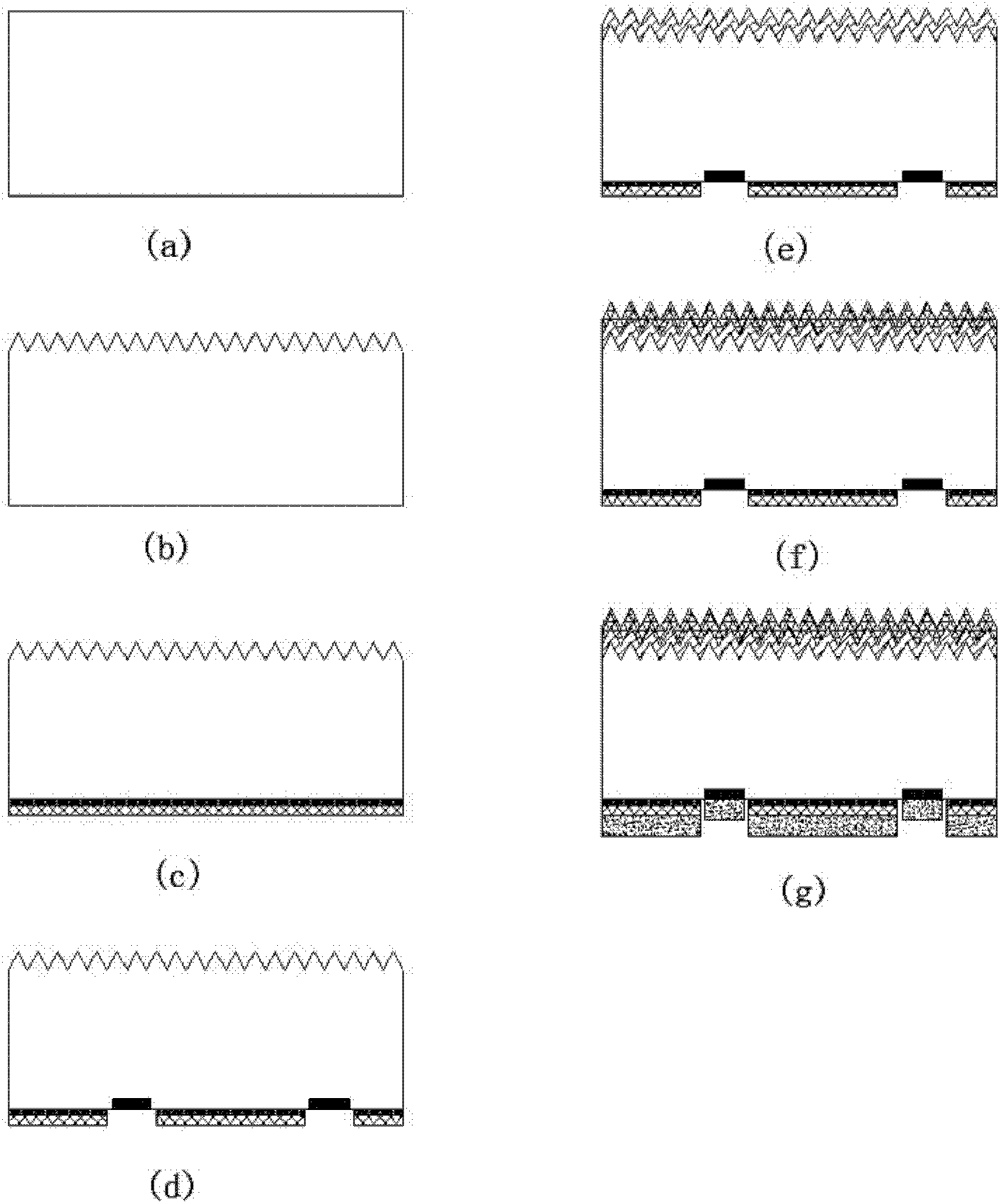

[0077] The structure of the new type IBC structure N-type silicon heterojunction cell is the same as in Example 1;

[0078] The preparation method of the novel IBC structure N-type silicon heterojunction cell in Example 3 is as follows:

[0079] (a) Select an N-type silicon substrate, and the resistivity of the N-type silicon substrate is 0.3??cm;

[0080] (b) Use potassium hydroxide solution to texture the surface of the N-type single crystal silicon substrate, prepare a pyramid-shaped light-trapping structure on the surface of the N-type silicon substrate, and perform chemical cleaning with a mixed solution of hydrochloric acid and hydrofluoric acid The concentration of potassium hydroxide solution is 0.5%; in hydrochloric acid and hydrofluoric acid mixed solution, hydrochloric acid: hydrofluoric acid ratio is 1:3; the concentration of hydrochloric acid and hydrofluoric acid mixed solution is 0.8%;

[0081] (c) Deposit intrinsic amorphous silicon and P-type amorphous silico...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com