Battery or capacitor packaging housing

A shell and capacitor technology, applied in capacitors, battery pack components, circuits, etc., can solve the problems of pinholes, large specific gravity, increase welding volume, etc., to prevent harmful explosions, small specific gravity, and improve strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

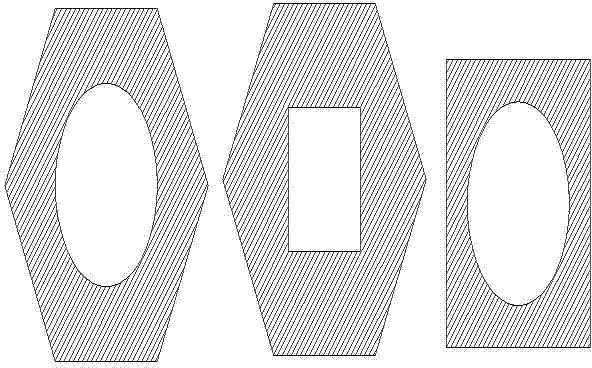

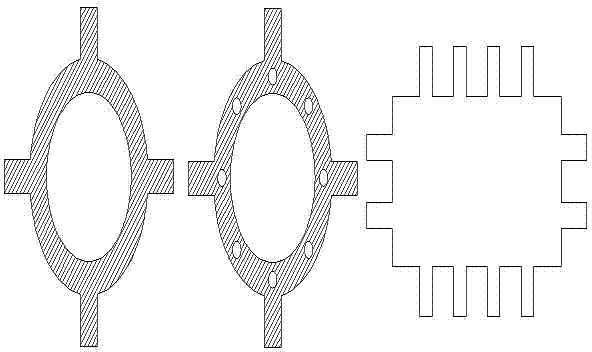

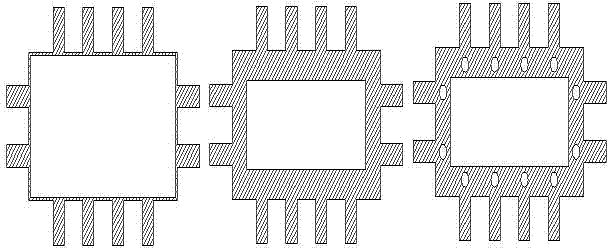

[0030] The purpose of the present invention is to provide a large-scale aluminum alloy (or magnesium alloy) housing for high-capacity and high-power energy storage batteries or capacitors used in the new energy industry and new energy automobile industry, which changes the existing simple mechanical stretching, Cutting and bending process, the aluminum alloy (or magnesium alloy) shell of the present invention is softened or melted at high temperature, and then manufactured through extrusion, drawing, die-casting, shaping and other processes. Compared with the simple mechanical stamping and bending manufacturing process, the shape and size of the shell body 01 are diversified, such as figure 2 , Figure 1-1 to Figure 1-5 , is a schematic diagram of the structural shapes of 15 shell bodies 01 manufactured by extrusion, drawing, die-casting, shaping and other processes.

[0031] refer to figure 2 , Figure 3-1 , Figure 3-2 and Figure 4 , The casing of the battery or capa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com