Process for machining electric spark small hole by using compound electrode

A composite electrode and processing technology, applied in electric processing equipment, electrode manufacturing, metal processing equipment, etc., can solve the problems of rising processing costs, no very effective solutions, affecting finishing, etc. Realize the effect of mature electroplating process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0019] The brass tubular composite electrode plated with chrome on the surface is prepared by electroplating, the degreased brass tubular electrode and the lead plate are placed in the plating tank filled with chromic acid plating solution, and the brass tubular electrode is connected to the negative pole of the DC power supply as Cathode; the lead plate is connected to the positive pole of the DC power supply as the anode, and the chromium ions in the chromic acid plating solution are electron-reduced to metal chromium atoms on the brass cathode, and the surface of the brass electrode is chromium-plated to form a chromium-plated brass Tubular composite electrode, the concentration of chromic acid plating solution used in the plating tank is 250g / L, and the current density of direct current is 60A / dm 2 , the area ratio of the cathode and anode plates is 1:10; the electroplating temperature is 60°C, and the coating thickness is 0.04mm;

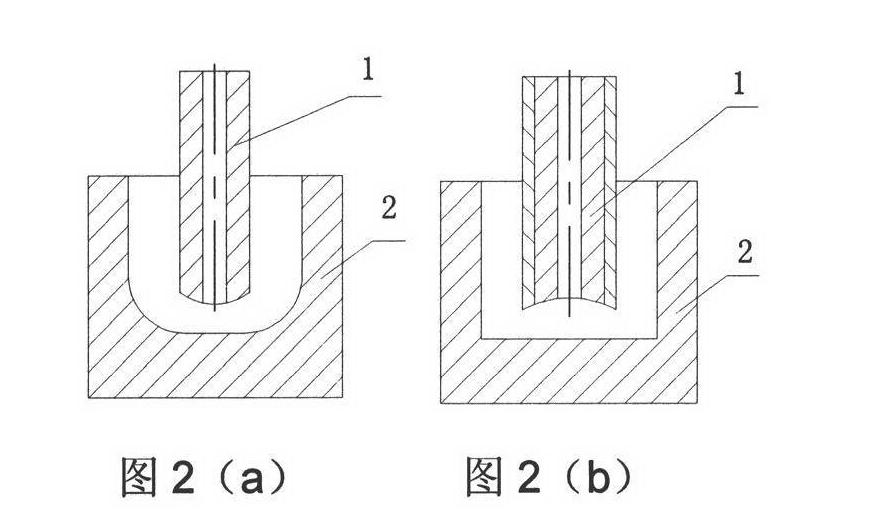

[0020] Use a brass tubular electrode wit...

Embodiment approach 2

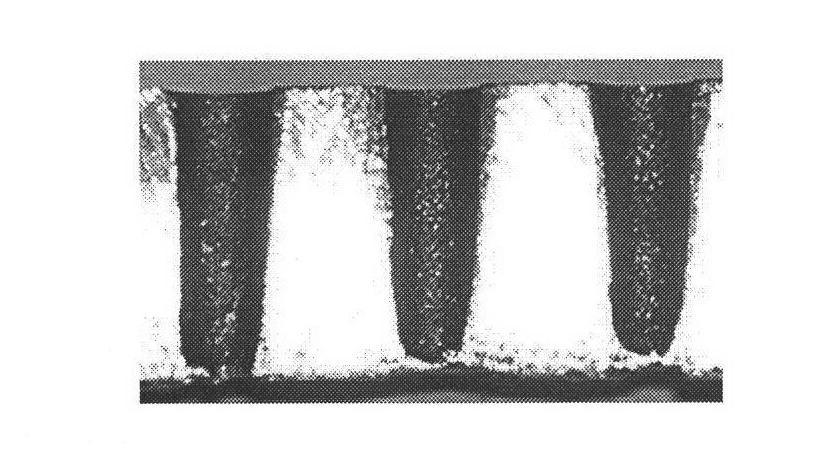

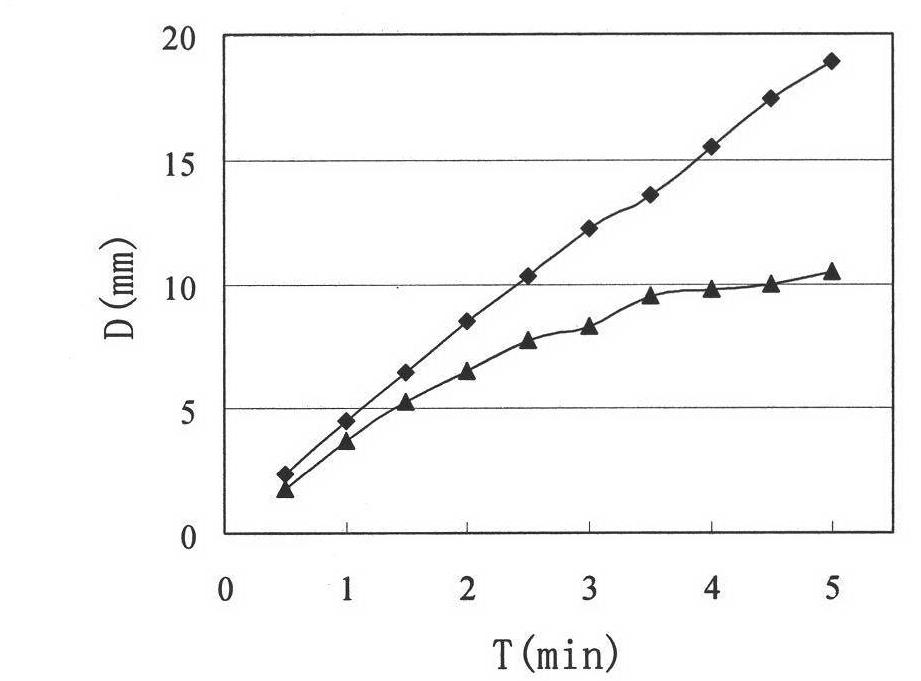

[0026] The concentration of the chromic acid plating solution used in the plating tank is 250g / L, and the current density of the direct current is 30A / dm 2, the area ratio of the cathode and anode plates is 1:5; the electroplating temperature is 40°C, and a new brass tubular electrode with an outer diameter of φ1.5mm and an inner diameter of φ0.3mm and a new brass tubular electrode with an outer diameter of φ1.54mm and an inner diameter of After processing the new chrome-plated brass tubular electrode of φ0.3mm for 5 minutes, the processed end of the comparison electrode is as attached Figure 5 shown. attached by Figure 5 It is obvious that after processing for a certain period of time, the processed end face of the composite electrode still maintains good cylindricity, while the processed end of the single brass electrode has a large taper, and there are obvious erosion gaps, which fully shows that the composite electrode can Improve the bell mouth problem of EDM. Others...

Embodiment approach 3

[0028] The concentration of the chromic acid plating solution used in the plating tank is 250g / L, and the current density of the direct current is 40A / dm 2 , the area ratio of the cathode and anode plates is 1:8; the electroplating temperature is 50°C, and the brass tubular electrode with an outer diameter of φ3.0mm and an inner diameter of φ0.47mm and a brass tubular electrode with an outer diameter of φ3.04mm and an inner diameter of φ0. The 47mm chrome-plated brass tubular electrode is used for small hole EDM processing on a D703F high-speed small hole EDM machine tool. During processing, the positive electrode of the pulse power supply is connected to the workpiece to be processed, the negative electrode is connected to the tool electrode, the working fluid is tap water, the pressure is 4Mp, the workpiece to be processed is a stainless steel plate with a thickness of 7.8mm, the rotation speed of the tool electrode is 120 rpm, and the processing voltage is 25V. The current ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com