Hot oil circulating and cold quenching fixed bed Fischer-Tropsch synthesis reactor and application thereof

A fixed-bed reactor, Fischer-Tropsch synthesis technology, which is applied in the petroleum industry, chemical instruments and methods, preparation of liquid hydrocarbon mixtures, etc., can solve the limitation of the amplification structure of a single reactor, increase the transfer limitation, and increase the resistance of the reactor and other problems, to achieve the effect of solving the limitation of catalyst production capacity, solving the problem of recycling and improving production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

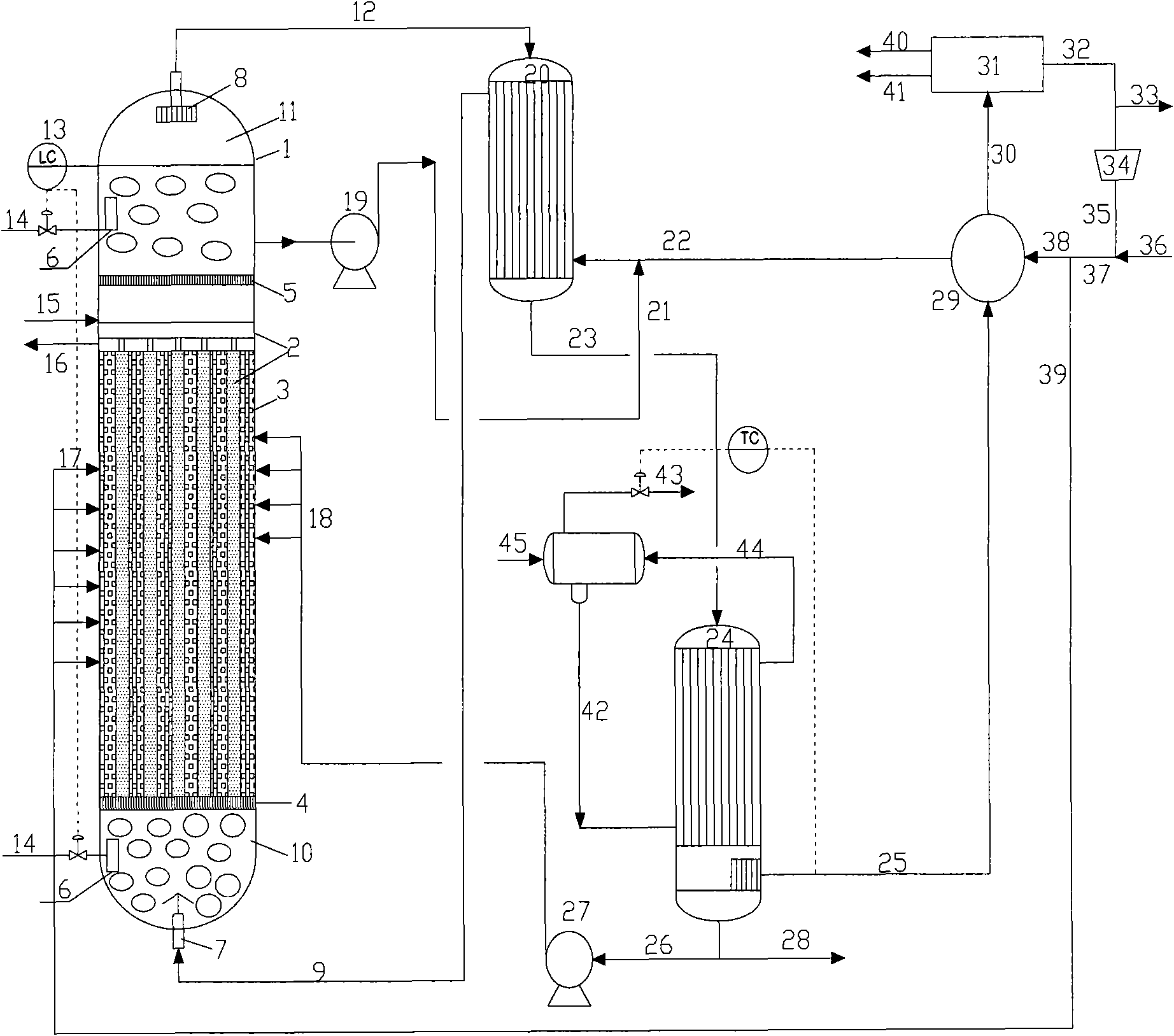

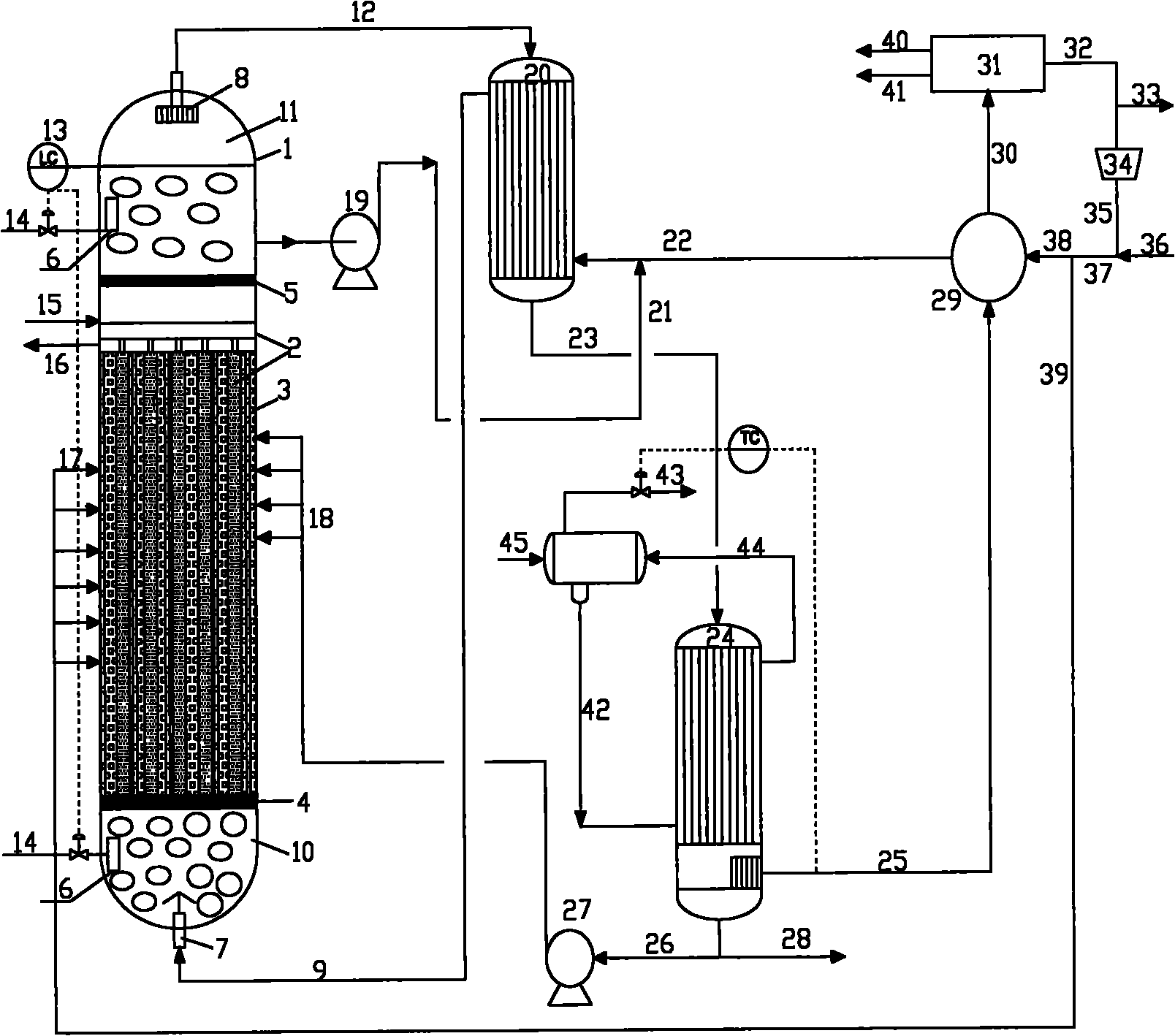

[0055] In the above-mentioned Fischer-Tropsch synthesis method of the present invention, in order to effectively regulate and control the temperature of the catalyst bed, a variety of enhanced heat removal measures have been adopted, including:

[0056] (1) apply the chilled gas chilling system provided in the reactor, and use the chilled gas as the chilling medium to carry out staged chilling of the catalyst bed;

[0057] (2) apply the light oil quenching system provided in this reactor, carry out segmental quenching to catalyst bed layer with light oil as quenching medium; With

[0058] (3) Use the hot oil circulation system installed in the reactor to extract part of the heavy liquid hydrocarbons from the fixed bed reactor, mix them with the synthesis gas mixture and exchange heat, and then enter the reactor through the bottom inlet of the reactor , so that the catalyst bed is completely immersed in the liquid state, so as to strengthen the indirect heat transfer of the hea...

Embodiment

[0072] Adopt the fixed-bed reactor system of the present invention, this reactor internal diameter is 5 meters, bed height 12 meters (height after expansion) during reaction, fills catalyst 180m altogether 3 . The catalyst used is a known cobalt-based catalyst 20wt% Co / HMS (Chinese patent ZL01111583.1) carried by industrial pure silicon mesoporous molecular sieves for fixed-bed Fischer-Tropsch synthesis. The cobalt-based catalyst is clover Columnar particles with an equivalent diameter of 1.8mm, a column length of 3mm, and a catalyst specific surface area of 420m 2 / g, pore volume 0.35cm 3 / g, bulk density 0.81g / cm 3 .

[0073] The Fischer-Tropsch synthesis reaction conditions are: reaction temperature 215°C, reaction pressure 50bar, feed gas H 2 / CO is 2.0, and the space velocity of feed gas is 722Nm 3 / m 3 catalyst / hour. According to the reaction data of the catalyst, its Thiele modulus is estimated to be 6.2. Reactor bed pressure drop 3-5bar, fresh gas volume 1300...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Equivalent diameter | aaaaa | aaaaa |

| Column length | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com