Method for preparing series of high-purity silver nanometer materials

A high-purity, silver nanotechnology, applied in the field of preparation of a series of silver nanomaterials, can solve the problems of large diameter changes of nanowires, complex reflux reaction devices, poor dispersion of synthetic products, etc., to achieve a wide range of size control, uniform shape, Good effect of monodispersity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

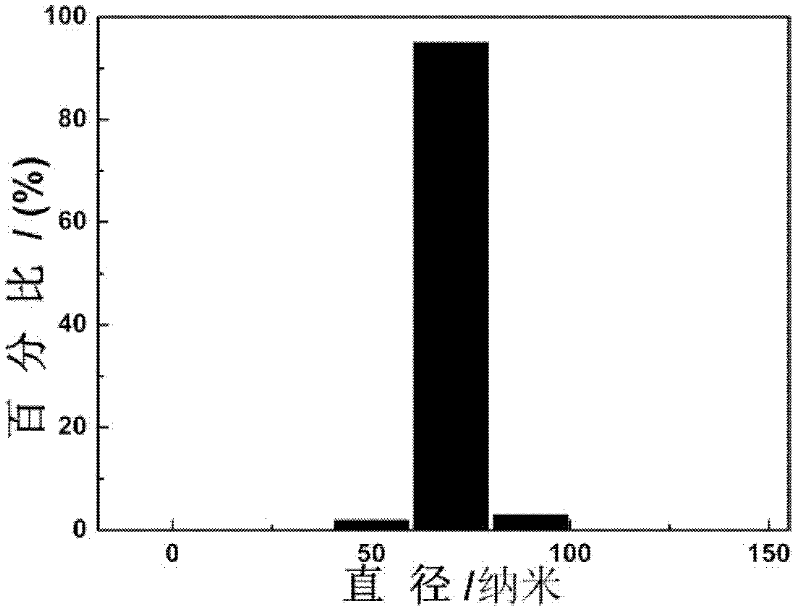

[0039]First prepare the mixed solution of ethylene glycol, polyvinylpyrrolidone and copper chloride: weigh 1 gram of polyvinylpyrrolidone and add it to 25 milliliters of ethylene glycol for stirring or ultrasonic dissolution, then add 6 mg of potassium bromide and 6 mg of copper chloride, Stir or ultrasonically dissolve evenly for later use. Then prepare the mixed solution of ethylene glycol and silver nitrate: weigh 1 gram of silver nitrate and add it to 25 ml of ethylene glycol, stir or oscillate to dissolve evenly and set aside. Then take 45 milliliters of ethylene glycol and add it to the reaction kettle, after ultrasonic heating for 30 minutes; then add 2 milliliters of water and continue ultrasonication for 15 minutes, then mix the prepared silver nitrate ethylene glycol solution, polyvinylpyrrolidone and copper chloride The ethylene glycol mixed solution was injected into the reaction kettle through a syringe pump at a speed of 1 ml / min at the same time. After the dropw...

Embodiment 2

[0041] Similar to the process of Example 1, but when preparing silver nanomaterials, the inorganic salt containing halide ions was replaced by potassium chloride by copper chloride, and the amount was reduced to 4 mg. The heating time of ethylene glycol ultrasonic heating was reduced to 15 minutes, and other conditions remained unchanged. After the reaction is finished, wash and centrifuge with ethanol and ultrapure water, and dry the precipitate at low temperature until it becomes a dry powder to obtain silver nanowires with a diameter of 40 nanometers. image 3 Scanning electron microscope image of a silver nanowire with a diameter of 40 nm, by image 3 It can be seen that the silver nanowires with a diameter of 40 nm still maintain an ultra-long axial length.

Embodiment 3

[0043] Similar to the process of Example 1, but when preparing silver nanomaterials, the dripping rate of the syringe pump was increased to 1.5 ml / min, and the addition was completed and heated at 160 degrees in a high-temperature furnace, and the heating time was reduced to 30 minutes, and other conditions remained constant. After the reaction is finished, wash and centrifuge with ethanol and ultrapure water, and dry the precipitate at low temperature until it becomes a dry powder, and silver nanowires with a diameter of 120 nanometers can be obtained. Figure 4 Scanning electron microscope image of a silver nanowire with a diameter of 120 nm, by Figure 4 , 5 It can be seen that while the diameter of silver nanowires increases, the axial length decreases slightly, but still maintains high purity and high monodispersity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com