Starch and polycaprolactone blend and preparation method and application thereof

A polycaprolactone and blend technology, which is applied in the field of preparation of starch and polycaprolactone blends, can solve the problems of lack of economical applicability, high denitrification cost, etc., and can overcome the dosage of carbon sources. It is not easy to control, the cost of denitrification is reduced, and the effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] After mixing 55 parts of cornstarch, 30 parts of polycaprolactone (molecular weight 60000), 14 parts of water and 1 part of KH-550 silane coupling agent, extrude and granulate in a twin-screw extruder at 130-170°C .

Embodiment 2

[0026] After stirring 40 parts of cornstarch, 40 parts of polycaprolactone (molecular weight 40000), 15 parts of water, 3 parts of wood flour and 2 parts of KH-560 silane coupling agent, in a twin-screw extruder at 130 to 170 ℃ extrusion granulation.

Embodiment 3

[0028] After stirring 30 parts of tapioca starch, 50 parts of polycaprolactone (molecular weight: 80000), 15 parts of water and 5 parts of wood flour evenly, extrude and granulate in a twin-screw extruder at 130-170°C.

[0029] Denitrification applications of starch / polycaprolactone blends:

[0030] 1. The hanging film of denitrifying microorganisms. The reactor is a packed bed mode, and the prepared blend particles (0.4 cm in diameter) are filled in the reactor, the filling height is two-thirds of the reactor, and water is fed in an upflow mode. The activated sludge from the aeration tank of the sewage treatment plant is added to the nitrate-containing raw water to domesticate the denitrifying microorganisms. After the denitrification effect is stable, the domestication ends.

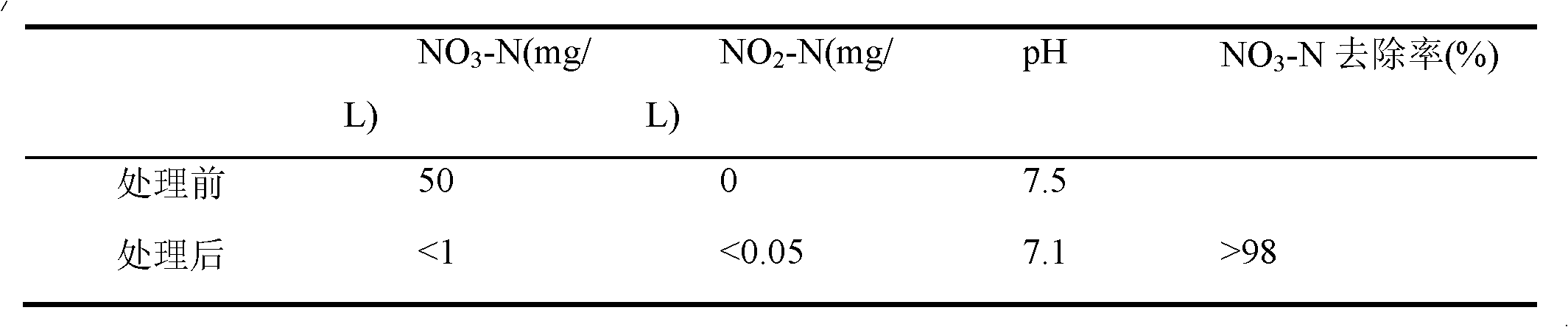

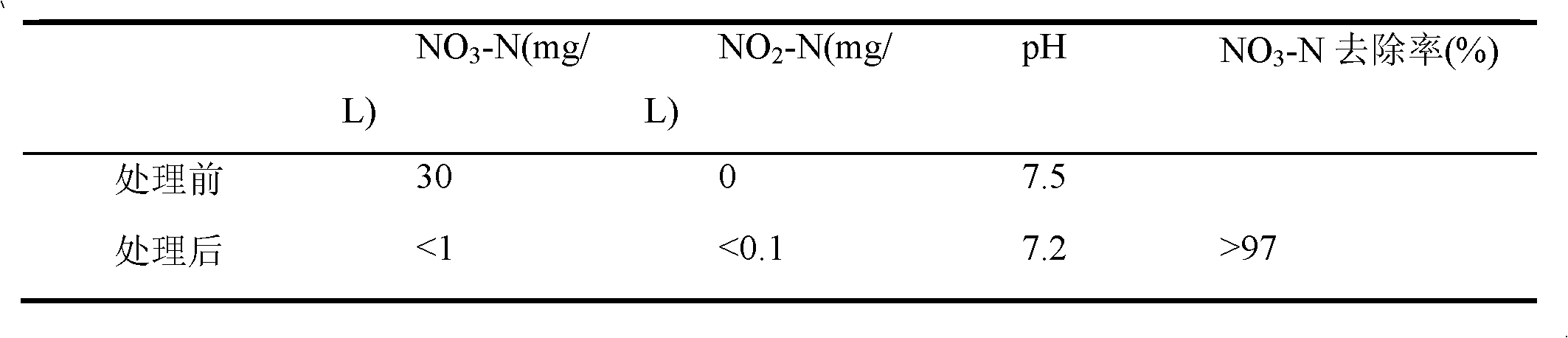

[0031] 2. Denitrification and denitrification. After the acclimatization is over, the normal operation of the reactor starts. The optimum temperature for acclimatization and operation is 25-30°C. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com