Chemical reaction method

A technology of chemical reaction and esterification reaction, applied in the field of chemical reaction, can solve the problems of high content of side reaction products and low selectivity, achieve the effects of shortening residence time, strengthening mass transfer process, and reducing the generation of by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

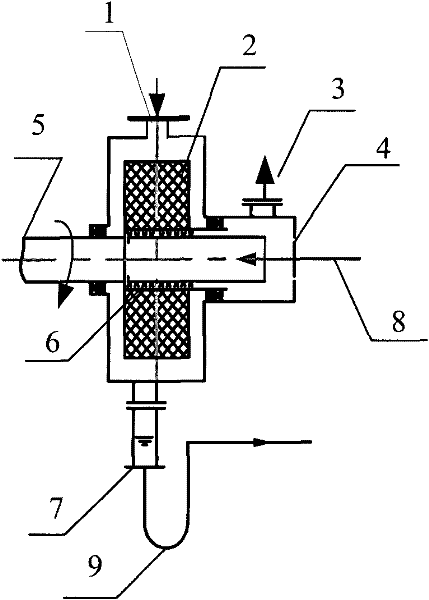

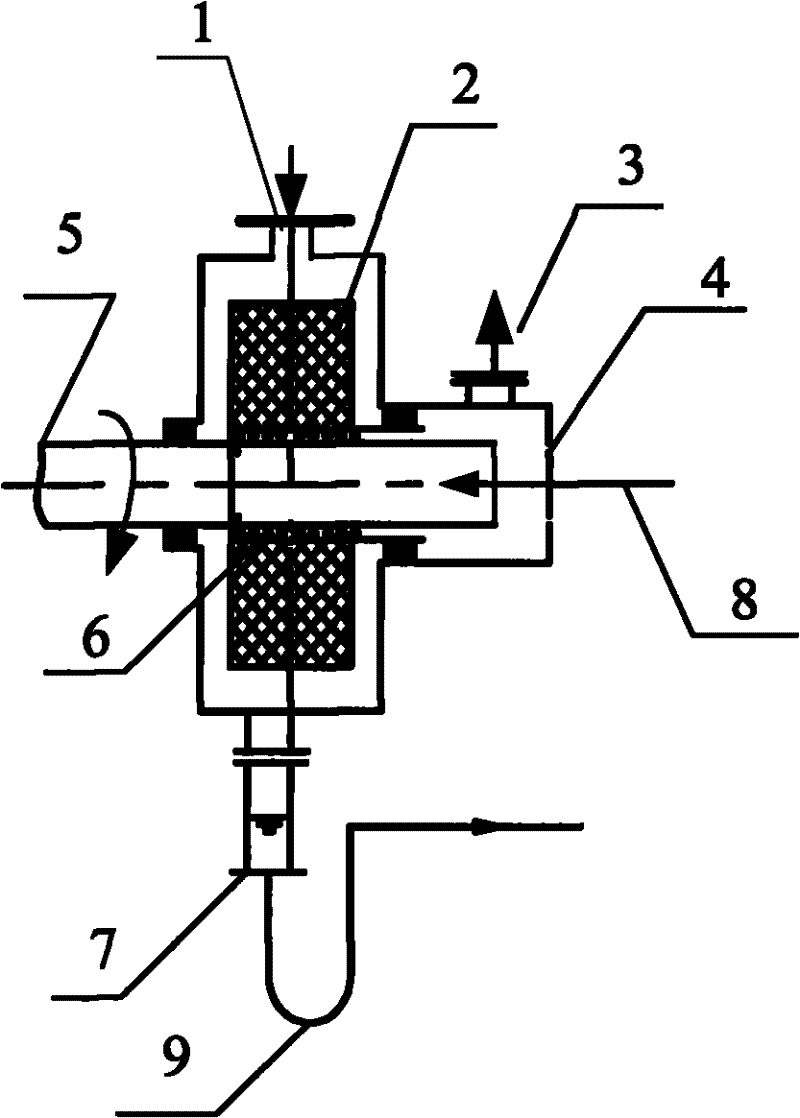

[0024] The esterification reaction of methanol, oxygen and NO is carried out in a high gravity reactor to produce methyl nitrite. Adopt attached figure 1 The supergravity reactor device shown.

[0025] The amount of raw material gas containing NO is 100m 3 / h, where the concentration of NO is 10%v (the rest is nitrogen), and the gas volume of oxygen is 2m 3 / h, the two gases enter the supergravity reactor through the gas inlet 1, and diffuse into the rotating packing 2 under the action of the pressure difference, and the rotating packing speed is adjusted to 2000 rpm. The methanol solution is introduced into the liquid distributor 6 and the inner side of the rotating packing 2 through the liquid inlet pipe 8 through the liquid inlet 4. The molar ratio of NO to methanol in the gas is 1:10, and the gas and liquid are in countercurrent contact in the packing, and the reaction product contains The gas effluent of methyl nitrite is discharged through the gas outlet 3, and the liquid e...

Embodiment 2

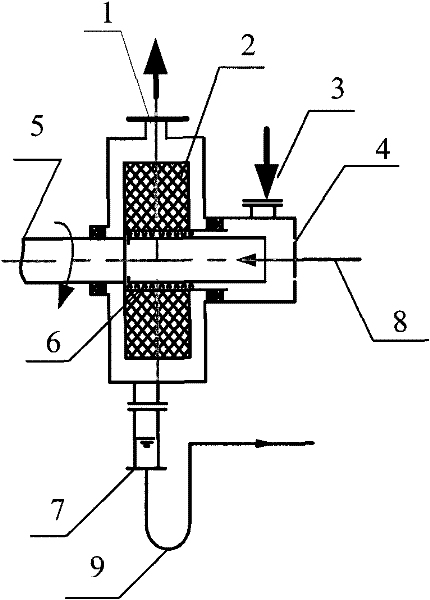

[0027] Esterification of ethanol, oxygen and NO is carried out in a high gravity reactor to produce ethyl nitrite. Adopt attached figure 2 The supergravity reactor device shown.

[0028] The amount of raw material gas containing NO is 100m 3 / h, where the concentration of NO is 15%v (the rest is nitrogen), and the gas volume of oxygen is 3m 3 / h, the two gases enter the high gravity reactor through the gas inlet 3, and diffuse into the rotating packing 2 under the action of the pressure difference, and the rotating packing speed is adjusted to 2000 rpm. The ethanol solution is introduced into the liquid distributor 6 and the inner side of the rotating packing 2 through the liquid inlet pipeline 8 through the liquid inlet 4. The molar ratio of NO to ethanol in the gas is 1:8, and the gas and liquid are in cocurrent contact in the packing, and the reaction product The gas effluent containing ethyl nitrite is discharged through the gas outlet 1, and the liquid effluent after the r...

Embodiment 3

[0030] Dehydrogenation of pyrolysis gasoline benzene acetylene is carried out in a high gravity reactor. Adopt attached figure 1 The supergravity reactor device shown.

[0031] Using theta alumina as the carrier, the nickel catalyst with a loading amount of 13% was prepared by the loading method. The liquid phase raw material is a carbon eight fraction containing 40% styrene, 10% ethylbenzene, and 0.1% phenylacetylene in terms of weight percentage. , The gas is hydrogen, and the catalyst is fixed on the rotating packing.

[0032] The hydrogen enters the high gravity reactor through the gas inlet 1, and diffuses into the rotating catalyst layer 2 under the action of the pressure difference, and the rotating speed of the rotating catalyst layer is adjusted to 3000 rpm. The carbon eight fraction solution containing phenylacetylene is introduced into the liquid distributor 6 and the inside of the rotating catalyst 2 through the liquid inlet line 8 through the liquid inlet 4. The hydro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com