Manganese-cerium composite oxide catalyst for removing medium-low concentration benzene series in air and preparation method thereof

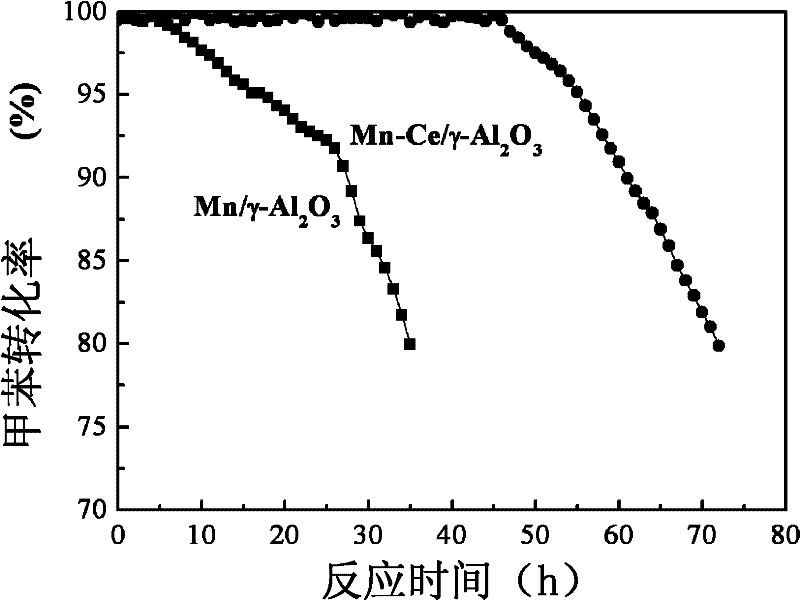

A technology of composite oxides and catalysts, applied in the direction of metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of low concentration of manganese oxides on the surface, incomplete oxidation, Rapid deactivation and other issues, to achieve uniform distribution, good support and dispersion, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

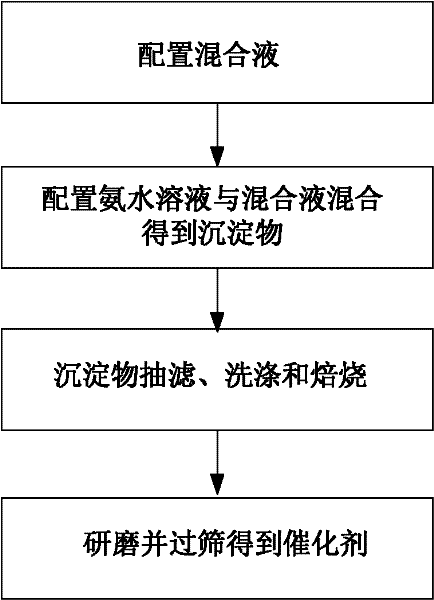

[0024] The invention provides a manganese-cerium composite oxide catalyst for removing low-concentration benzene series in the air and a preparation method thereof. The process flow of the preparation method is as follows image 3 As shown, it is specifically prepared by the following steps:

[0025] The first step is to configure the mixture. Al(NO 3 ) 3 , Mn(NO 3 ) 2 and Ce(NO 3 ) 3 The solution is mixed according to the ratio of the Mn / Al atomic ratio of 1:110 to 3:11 and the Mn / Ce atomic ratio of 1:10 to 10:1 to obtain a mixed solution;

[0026] The second step is to prepare an ammonia solution and prepare a precipitate. Prepare NH with a mass fraction of 20% to 30% 3 ·H 2 O solution, and the mixed solution obtained in the first step was added dropwise to NH at a constant rate (1-3 drops / second). 3 ·H 2 O solution (pH titration end point is 8-9), keep stirring at a constant speed during the dropwise addition process to obtain a precipitate.

[0027] The third s...

Embodiment 1

[0032] Catalyst preparation: Al(NO with a concentration of 0.5mol / L 3 ) 3, 0.5mol / L Mn(NO 3 ) 2 and 0.5mol / L Ce(NO 3 ) 3 Fully mix according to the ratio of Mn / Al atomic ratio of 1:11 and Mn / Ce atomic ratio of 5:1 to obtain a mixed solution; prepare a mass percent concentration of 20% NH 3 ·H 2 O solution, and the aforementioned mixed solution was added dropwise to NH at a constant rate (1 drop / second) 3 ·H 2 In O solution (pH titration end point is 8.0), the dropwise addition process keeps stirring at a constant speed, and a precipitate is obtained. After the precipitation is complete, age the precipitate in a water bath at 50°C for 2 hours, then filter the precipitate with suction, wash with deionized water for 3 times, dry at 100°C for 10 hours, and roast in a muffle furnace at 300°C for 3 hours to grind the obtained sample and sieved to 40-60 mesh to obtain the manganese-cerium composite oxide catalyst.

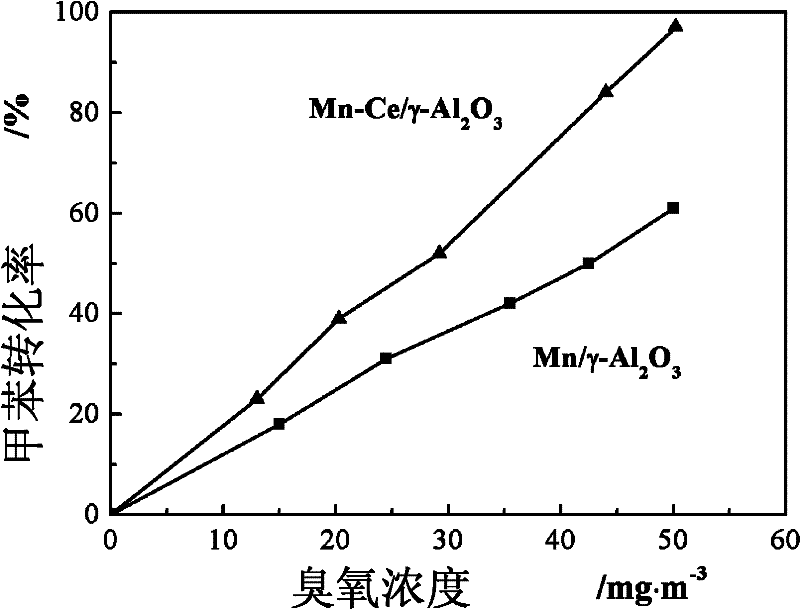

[0033] Perform a performance test on the catalyst obtained ...

Embodiment 2

[0035] Catalyst preparation: Al(NO with a concentration of 1.0mol / L 3 ) 3 , 0.5mol / L Mn(NO 3 ) 2 and 0.1mol / L Ce(NO 3 ) 3 Fully mix according to the ratio of Mn / Al atomic ratio of 3:11 and Mn / Ce atomic ratio of 1:5 to obtain a mixed solution; prepare NH with a mass percentage concentration of 30%. 3 ·H 2 O solution, and the aforementioned mixed solution was added dropwise to NH at a constant rate (2 drops / sec) 3 ·H 2 O solution (pH titration end point is 8.3), keep constant stirring during the dropwise addition process, and precipitates are constantly precipitated; after the precipitation is complete, age the precipitates in a 50°C water bath for 3 hours, then filter the precipitates with suction, and wash them with deionized water for 4 hours. Next, dry at 110° C. for 11 h, bake in a muffle furnace at 400° C. for 4 h, grind the obtained sample and sieve it to 40-60 meshes to obtain the manganese-cerium composite oxide catalyst of the present invention.

[0036] Cataly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com