Preparation method of high efficient sulfonated carbon solid acid catalyst

A solid acid catalyst, sulfonated carbon technology, applied in the preparation of organic compounds, catalysts for physical/chemical processes, preparation of carboxylate, etc. High and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

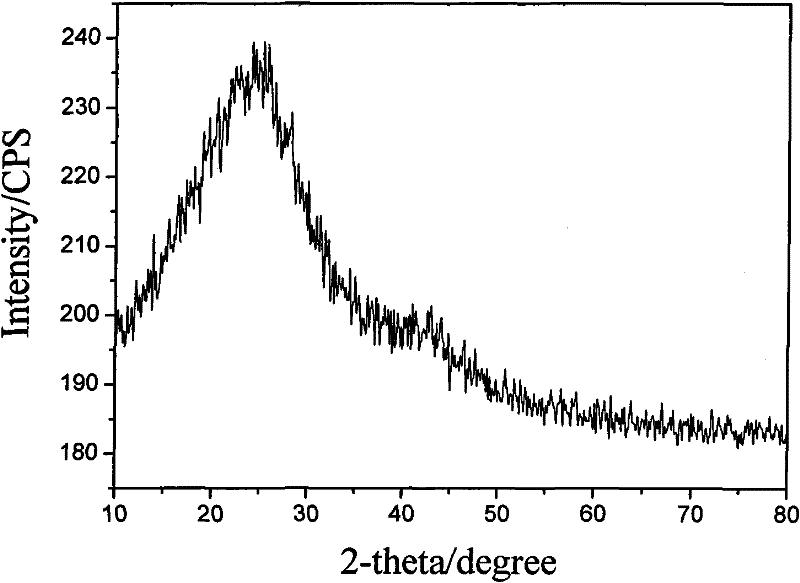

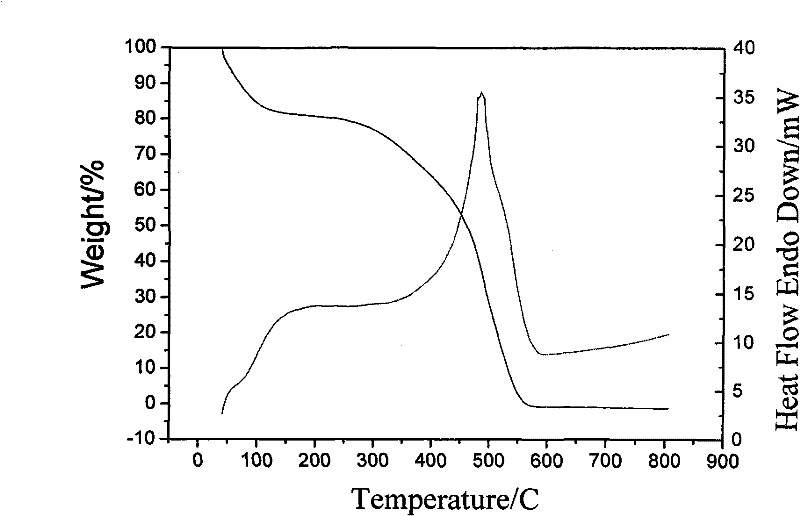

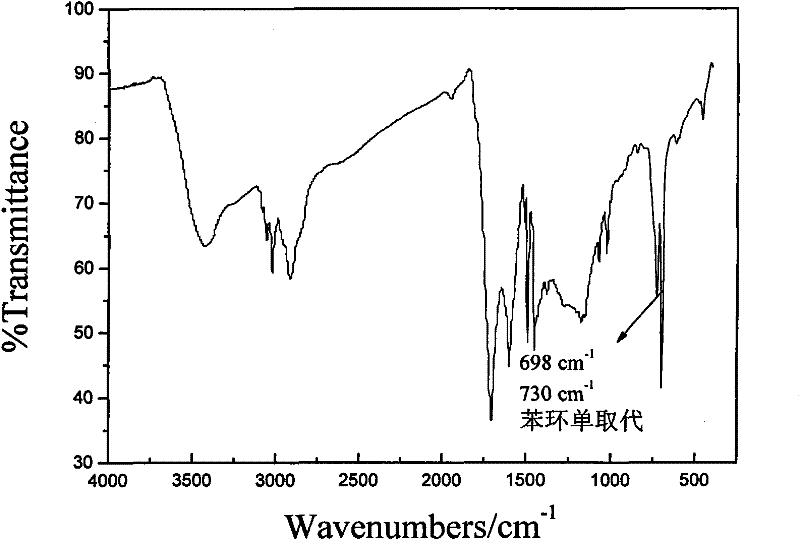

Method used

Image

Examples

Embodiment 1

[0017] Weigh the cellulose and benzyl chloride at a mass ratio of 4:1, place them in a stainless steel pressure vessel lined with polytetrafluoroethylene, stir and mix them evenly, react in an oven at 160°C for 24 hours, take them out and cool them, and grind them , filtered and washed with deionized water and ethanol, and the obtained solid was dried in an oven at 90°C; the solid and concentrated sulfuric acid were placed in a stainless steel pressure vessel with a polytetrafluoroethylene liner at a mass ratio of 1:10, and evenly After stirring and mixing, sulfonate in an oven at 160°C for 24 hours, take it out and cool it, grind it, wash it with deionized water and ethanol at 90°C, and dry it in an oven at 90°C to obtain the required catalyst. The surface acid content measured by acid-base titration is 4.59mmol / g, and the sulfonate group content is 1.38mmol / g.

Embodiment 2

[0019] After weighing glucose and phenol according to the mass ratio of 4:2, add a small amount of N,N-dimethylformamide as a solvent, place it in a stainless steel autoclave lined with polytetrafluoroethylene, stir and mix it evenly, and heat it at 160°C React in the oven for 24 hours, take it out to cool, after grinding, filter and wash with deionized water and ethanol, and dry the obtained solid in an oven at 90°C; take this solid and concentrated sulfuric acid in a mass ratio of 1:10 and place it in a belt polymer In a stainless steel autoclave lined with tetrafluoroethylene, after uniform stirring and mixing, react in an oven at 160°C for 24 hours, take it out and cool it, after grinding, wash it with 90°C deionized water and ethanol, and then put it in an oven at 90°C for drying After drying, the desired catalyst is obtained. The surface acid content measured by acid-base titration is 4.18mmol / g, and the sulfonate group content is 1.25mmol / g.

Embodiment 3

[0021] Weigh sucrose and diphenylchloromethane in a mass ratio of 4:2, place them in a stainless steel autoclave lined with polytetrafluoroethylene, stir and mix evenly, react in an oven at 160°C for 24 hours, take them out and cool them, and grind them , filtered and washed with deionized water and ethanol, and the obtained solid was dried in an oven at 90°C; the solid and concentrated sulfuric acid were placed in a stainless steel pressure vessel with a polytetrafluoroethylene liner at a mass ratio of 1:10, and evenly After stirring and mixing, react in an oven at 160°C for 24 hours, take it out and cool it, grind it, wash it with deionized water and ethanol at 90°C, and dry it in an oven at 90°C to obtain the required catalyst. The surface acid content measured by acid-base titration is 4.25mmol / g, and the sulfonate group content is 1.43mmol / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com