Method for preparing alkyl nitrite

A technology of alkyl nitrite and alkanol, applied in the preparation of nitrite, organic chemistry, etc., can solve the problem of low selectivity of alkyl nitrite, achieve simple structure, improve conversion rate, and ensure residence time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

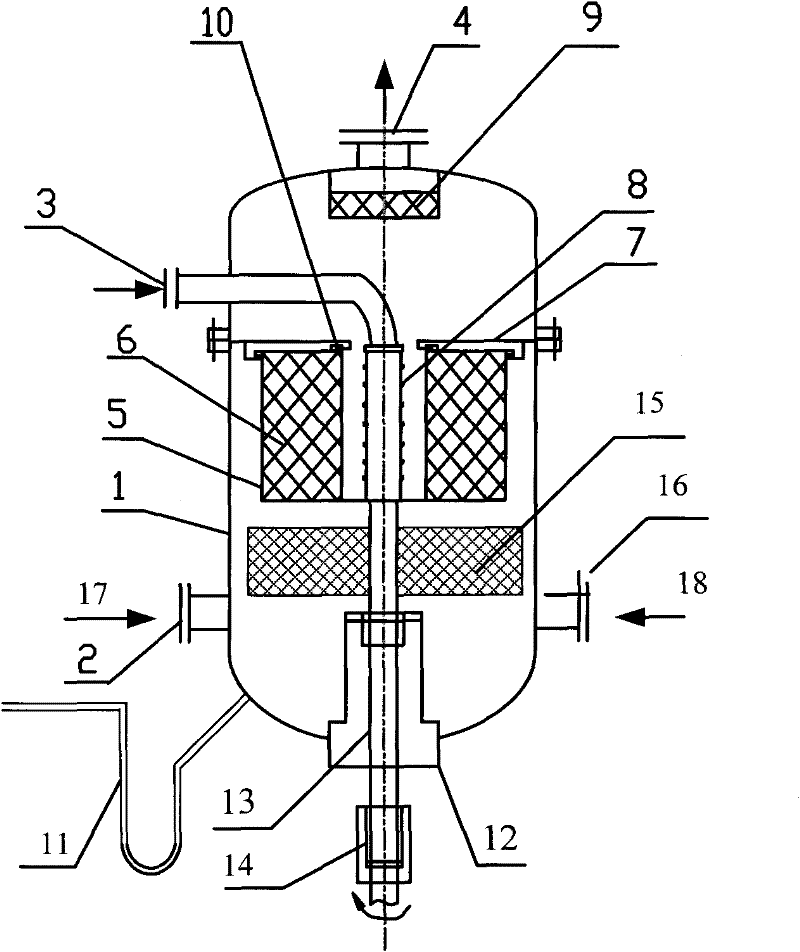

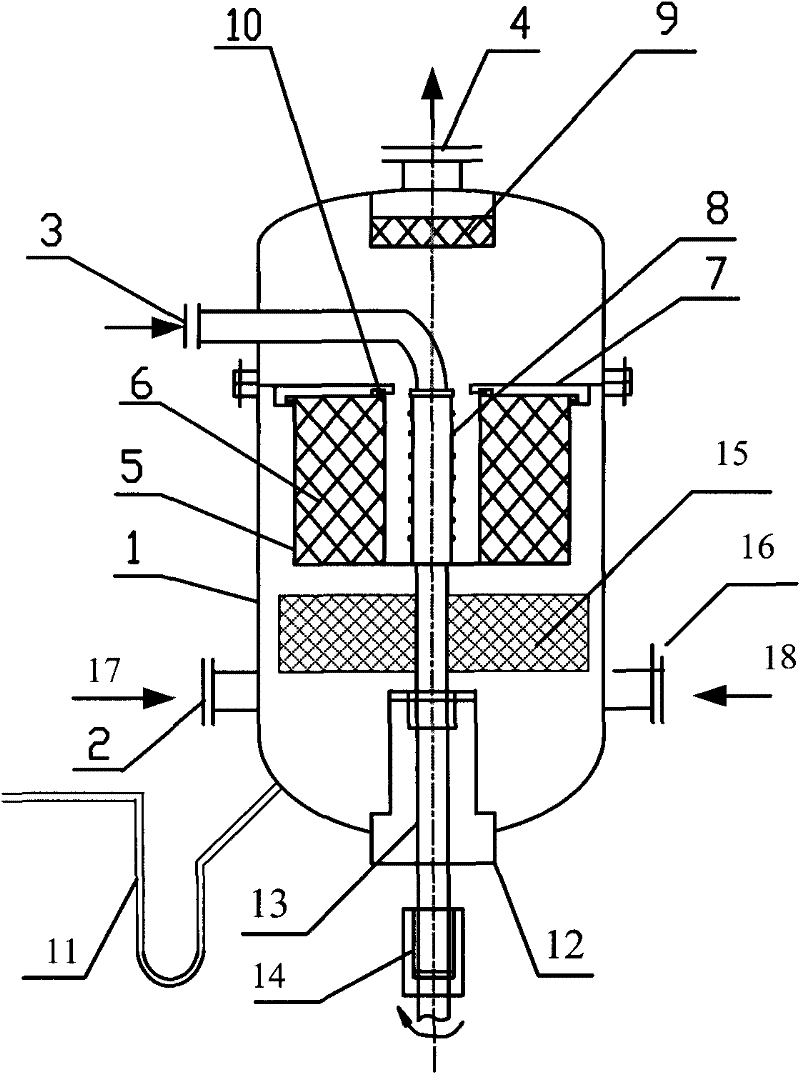

[0024] Below in conjunction with accompanying drawing, the equipment of the method for preparing alkyl nitrite of the present invention is described in detail.

[0025] The supergravity reactor in the method for preparing alkyl nitrite of the present invention adopts and comprises reactor housing 1, rotor 5, gas partition 7, liquid inlet 3 and gas outlet 4, wherein the upper gravity reactor is set The packing layer 6 and the lower packing layer 15, the lower side of the lower packing layer 15 is also provided with a first gas inlet 2 and a second gas inlet 16, the two gas inlets respectively enter the nitrogen oxide gas raw material and oxygen, and the liquid inlet 3 tubes A liquid distributor 8 is arranged in the road, and the liquid inlet 3 enters C1-C4 alkyl alcohol. The upper packing layer 6 and the lower packing layer 15 in the high gravity reactor are two layers of coaxial packing layers, and the gas outlet 4 of the high gravity reactor is provided with a foam catcher 9 ...

Embodiment 1

[0030] The gas volume of the first gas containing nitrogen oxide raw material is 100m 3 / h, wherein the concentration of NO is 10% v (the rest is nitrogen), and the gas volume of the second gas oxygen is 2m 3 / h, the two gases enter the supergravity reactor from the first gas inlet 2 and the second gas inlet 16 respectively, and diffuse into the lower packing 15 under the action of the pressure difference, and the rotating packing speed is adjusted to 2000rpm. The methanol solution enters the liquid distributor 8 of the supergravity reactor through the liquid inlet 3 and is sprayed to the inner side of the packing. The molar ratio of nitrogen oxides and methanol liquid in the gas is 1:30, and the gas and liquid are in the upper packing layer 6 of the supergravity reactor. In countercurrent contact, the reaction generates gaseous effluent I and liquid effluent II containing methyl nitrite. The gas effluent I containing methyl nitrite is sent to the follow-up system through the...

Embodiment 2

[0032] The gas volume of the first gas containing nitrogen oxide raw material is 100m 3 / h, wherein, the concentration of NO is 21% v (the rest is nitrogen), the gas volume of the second gas oxygen is 3.8m 3 / h, the two gases enter the supergravity reactor from the first gas inlet 2 and the second gas inlet 16 respectively, and diffuse into the lower packing 15 under the action of the pressure difference, and the rotating packing speed is adjusted to 4000rpm. The methanol solution enters the liquid distributor 8 of the supergravity reactor through the liquid inlet 3 and is sprayed to the inner side of the packing. The molar ratio of nitrogen oxides and methanol liquid in the gas is 1:15, and the gas and liquid are in the upper packing layer 6 of the supergravity reactor. In countercurrent contact, the reaction generates gaseous effluent I and liquid effluent II containing methyl nitrite. The gas effluent I containing methyl nitrite is sent to the follow-up system through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com