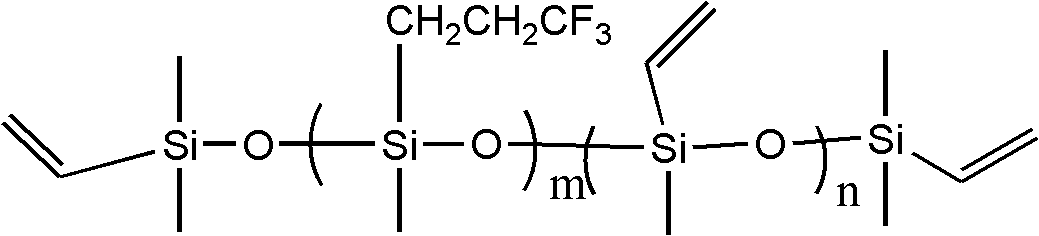

High-strength fluorinated silicone rubber gross rubber and preparation method thereof

A technology of fluorosilicone rubber and mixed rubber, which is applied in the field of rubber, and can solve problems such as unstable product performance and uneven vinyl distribution, and achieve high elongation at break, improved mechanical properties, and good tear strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

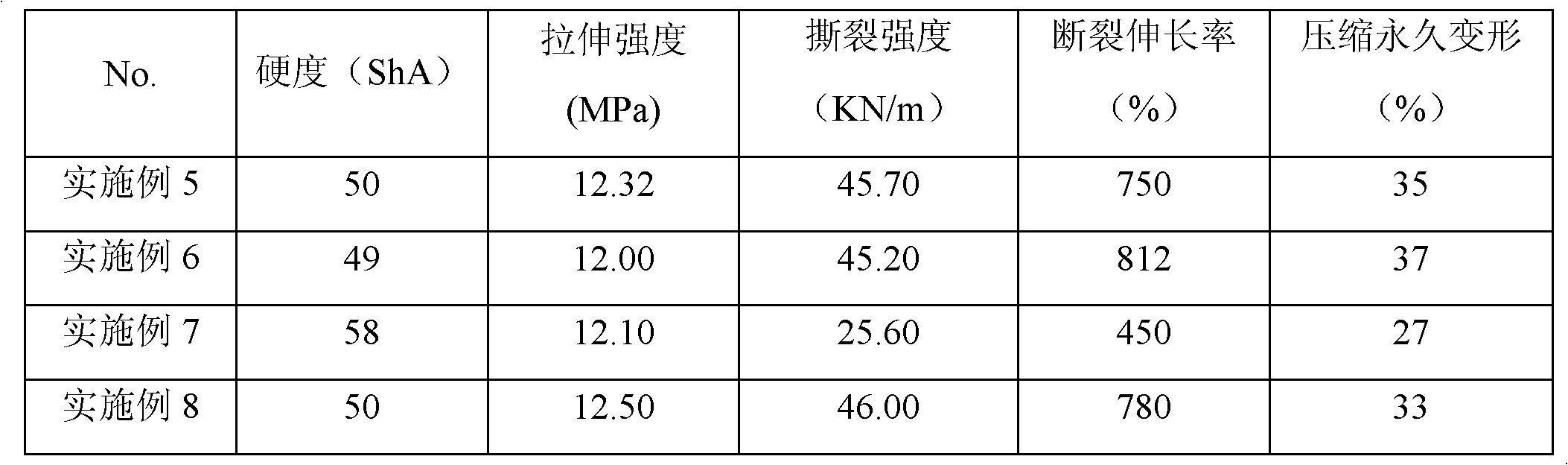

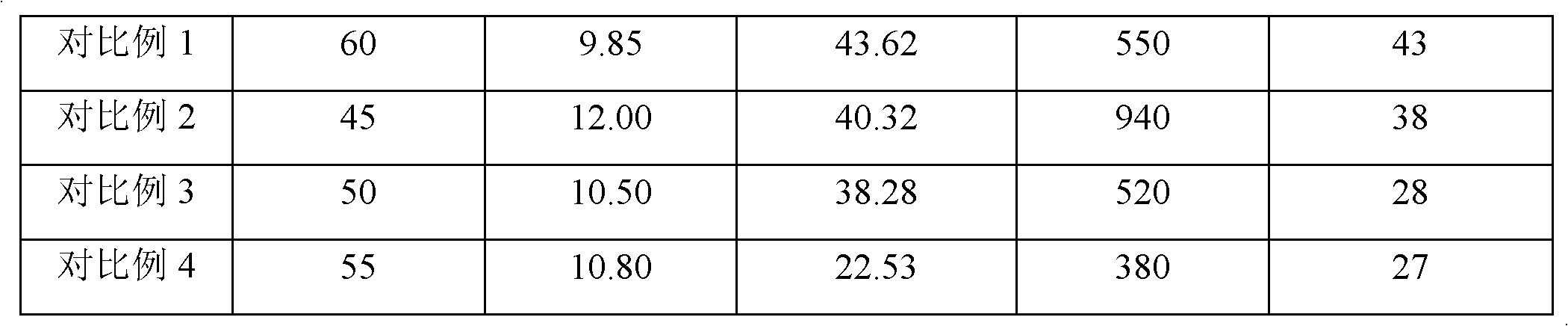

Examples

Embodiment 1

[0028] Preparation of fluorosilicone rubber crosslinking agent:

[0029] Mix 375g of 3,3,3-trifluoropropylmethyldichlorosilane and 125g of methylvinyldichlorosilane and slowly drop them into a reactor filled with 2000g of distilled water. Remove the water layer, wash the hydrolyzate with saturated sodium bicarbonate solution until neutral, dry it with anhydrous calcium chloride, add it to a four-necked flask, then add 10 g of potassium hydroxide, raise the temperature to 160°C, and collect fractions under a reduced pressure of 13.3 to 200 Pa. A ring body containing a methyltrifluoropropylsiloxane chain unit and a methylvinylsiloxane chain unit is obtained, which may be one or more of a tricyclic body, a tetracyclic body or a pentacyclic body, and the yield is 70% %.

[0030] Put 100g of the cyclic body obtained by cracking into the polymerization reactor for dehydration. The dehydration conditions are -0.01~-0.02MPa, 60~80℃, 0.5~2h, dry nitrogen and ventilate, then raise the ...

Embodiment 2

[0032] Preparation of fluorosilicone rubber crosslinking agent:

[0033] Mix 375g of 3,3,3-trifluoropropylmethyldichlorosilane and 125g of methylvinyldichlorosilane and slowly drop them into a reactor filled with 2000g of distilled water. Remove the water layer, wash the hydrolyzate with saturated sodium bicarbonate solution until neutral, dry it with anhydrous calcium chloride, add it to a four-necked flask, then add 10 g of potassium hydroxide, raise the temperature to 160°C, and collect fractions under a reduced pressure of 13.3 to 200 Pa. A ring body containing a methyltrifluoropropylsiloxane chain unit and a methylvinylsiloxane chain unit is obtained, which may be one or more of a tricyclic body, a tetracyclic body or a pentacyclic body, and the yield is 70% %.

[0034] The ring body 100g obtained by cleavage, D 3 F 200g is added to the polymerization reactor for dehydration. The dehydration conditions are -0.01~-0.02MPa, 60~80℃, 0.5~2h, dry nitrogen and ventilate, then...

Embodiment 3

[0036] Preparation of fluorosilicone rubber crosslinking agent:

[0037] Mix 375g of 3,3,3-trifluoropropylmethyldichlorosilane and 125g of methylvinyldichlorosilane and slowly drop them into a reactor filled with 2000g of distilled water. Remove the water layer, wash the hydrolyzate with saturated sodium bicarbonate solution until neutral, dry it with anhydrous calcium chloride, add it to a four-necked flask, then add 10 g of potassium hydroxide, raise the temperature to 160°C, and collect fractions under a reduced pressure of 13.3 to 200 Pa. A ring body containing a methyltrifluoropropylsiloxane chain unit and a methylvinylsiloxane chain unit is obtained, which may be one or more of a tricyclic body, a tetracyclic body or a pentacyclic body, and the yield is 70% %.

[0038] The ring body 50g obtained by cleavage, D 3F 200g is added to the polymerization reactor for dehydration. The dehydration conditions are -0.01~-0.02MPa, 60~80°C, 0.5~2h, dry nitrogen and ventilate, then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com