Beneficiation method for comprehensive recovery of valuable metals from sulfuric acid residues through chlorination and segregation

A valuable metal and ore dressing method technology, applied in the direction of flotation, solid separation, process efficiency improvement, etc., to achieve comprehensive recovery, resource utilization, and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

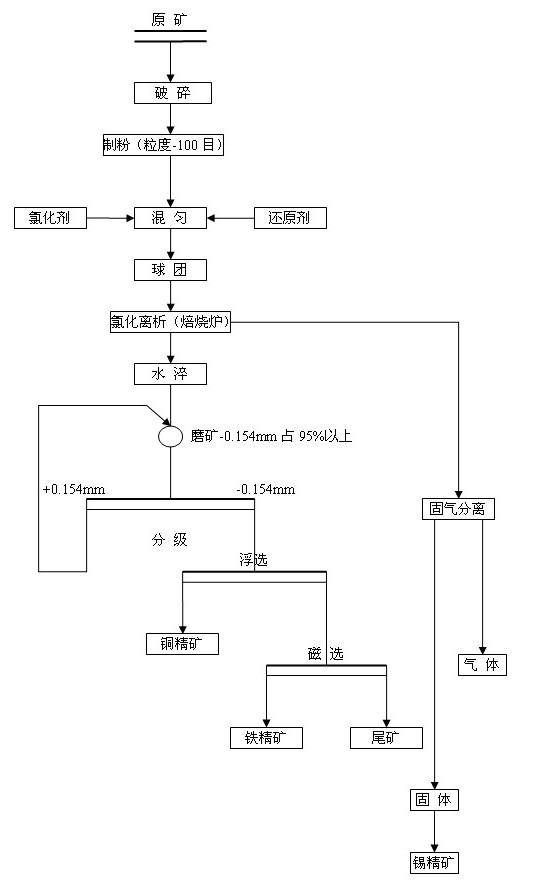

Method used

Image

Examples

Embodiment 1

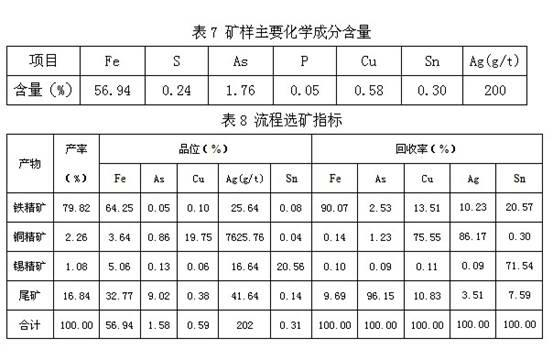

[0019] The ore sample (sulfuric acid slag) comes from a certain place in Yunnan. The raw ore contains 56.94% iron, 2.14% sulfur, and 1.96% arsenic. It belongs to the high-sulfur, high-arsenic and copper-containing sulfuric acid slag. Crush the ore sample until the particle size is less than 5mm, and prepare the ore sample with a particle size of -100 mesh through pulverizing equipment. The amount of coke is 6% (relative to the mass fraction of the ore, the same below), and the amount of calcium chloride is 8% (relative to The mass fraction of the ore, the same below), the coke particle size is -0.5mm, the ore sample, coke, and calcium chloride are mixed, and the pellets are prepared by pelletizing equipment; the pellets are placed in a roaster for chlorination and segregation Roasting, the roasting temperature is 1050°C, and the roasting time is 50 minutes; the chlorinated and separated products in the roasting furnace are quenched in water, and the time is less than 15 seconds...

Embodiment 2

[0022] The ore sample comes from a certain place in Sichuan. The raw ore contains 46.94% iron, 0.34% sulfur, 1.96% arsenic, 0.6% copper and 0.40% tin. Crush the ore sample until the particle size is less than 5mm, and prepare the ore sample with a particle size of -100 mesh through pulverizing equipment. The amount of coke is 5%, the amount of calcium chloride is 8%, and the particle size of coke is -0.5mm. Calcium chloride is mixed evenly, and pelletizing equipment is used to prepare pellets; the pellets are placed in a roaster for chlorination and segregation roasting, the roasting temperature is 900 ° C, and the roasting time is 120 minutes; the products chlorinated and isolated in the roaster are quenched in water , the time is less than 15 seconds; the grinding machine grinds the segregated product to a particle size of -0.154mm, flotation recovers copper to obtain copper concentrate, magnetic separation process recovers iron to obtain iron concentrate, and tail gas recove...

Embodiment 3

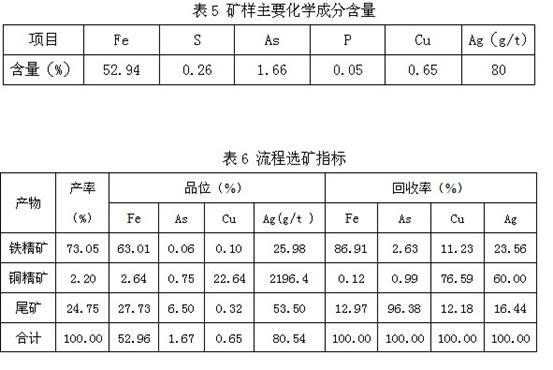

[0025] The ore sample comes from a certain place in Guizhou. The raw ore contains 52.94% iron, 1.66% arsenic, 0.6% copper, and 80g / t silver. It belongs to high-arsenic copper-silver sulfate slag. Crush the ore sample until the particle size is less than 5mm, and prepare the ore sample with a particle size of -100 mesh through pulverizing equipment. The amount of coke is 2%, the amount of calcium chloride is 3%, and the particle size of coke is -0.5mm. Calcium chloride is mixed evenly, and pelletizing equipment is used to prepare pellets; the pellets are placed in a roaster for chlorination and segregation roasting, the roasting temperature is 1000 ° C, and the roasting time is 80 minutes; the products chlorinated and isolated in the roaster are quenched in water , the time is less than 15 seconds; the ore mill grinds the segregated product to a particle size of -0.154mm, the flotation recovers copper to obtain copper-silver mixed concentrate, and the magnetic separation process...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com