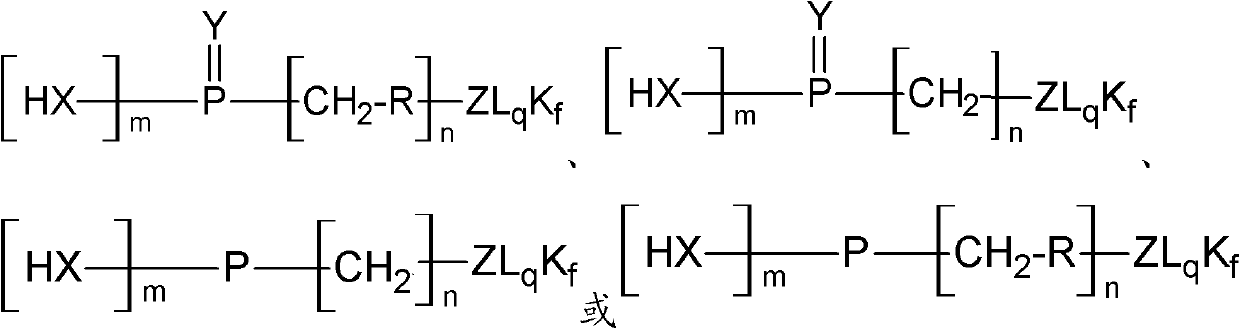

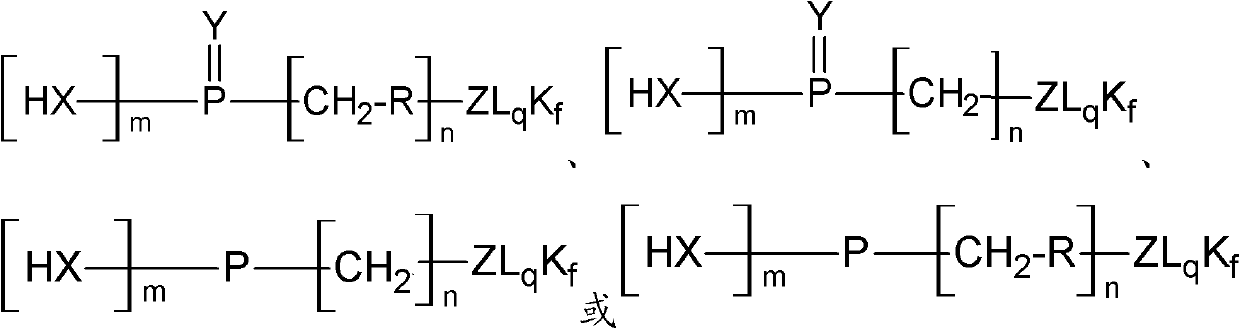

Hydrolysis-resistant phosphorus-containing polyhydric alcohol acrylic ester and preparation method thereof

An alcohol acrylate, hydrolysis-resistant technology, applied in the field of polymerizable functional monomers and preparation, can solve problems such as corrosion of metal substrates, damage to electronic devices, alkali resistance of cured films, and effects of weather resistance, and achieve water resistance. Excellent solution performance, improved performance, adjustable phosphorus content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: Preparation of trihydroxymethylphosphine oxide triacrylate

[0029] In a reaction kettle equipped with temperature control equipment, agitator, and reflux condenser, add 140Kg of trishydroxymethylphosphine oxide, 250Kg of acrylic acid, 150Kg of toluene, 5.2Kg of catalyst p-toluenesulfonic acid, and 2.5 kg of polymerization inhibitor p-methoxyphenol Kg, then stirred and heated to reflux, reflux reaction for 7h, and continuously discharged the water generated in the reaction system, so that the reaction proceeded in a direction that was conducive to the formation of the product; after calculating the amount of water to the theoretical value, the reaction was terminated; the reaction mixture was cooled To 30°C, add 250Kg mass concentration of 10% sodium hydroxide solution to wash once, separate the water phase, filter the organic phase and the middle layer together, then wash the organic phase with deionized water until neutral, dry the organic phase; Organic s...

Embodiment 2

[0030] Embodiment 2: Preparation of trihydroxyethylphosphine oxide triacrylate

[0031] In the reaction kettle equipped with temperature control equipment, agitator, and reflux condenser, add 182Kg of trihydroxyethylphosphine oxide, 255Kg of acrylic acid, 150Kg of cyclohexane, 5.4Kg of catalyst p-toluenesulfonic acid, and 5.4Kg of polymerization inhibitor p-methoxy Phenol 2.5Kg, then stirred and heated, rapid reflux reaction for 15h, and the water generated in the reaction system was continuously discharged, so that the reaction proceeded in a direction that was conducive to the generation of products; the reaction was terminated after the amount of water was calculated to the theoretical value; the reaction mixture was Cool to 30°C, add 250Kg mass concentration of 10% sodium hydroxide solution to wash once, separate the water phase, filter the organic phase and the middle layer together, then wash the organic phase with deionized water until neutral, dry the organic phase; Th...

Embodiment 3

[0032] Embodiment 3: Preparation of trihydroxymethylphosphine trimethacrylate

[0033] In a stainless steel reaction kettle equipped with temperature control equipment, agitator, and reflux condenser, add 124Kg of refined trihydroxymethylphosphine, 300Kg of methacrylic acid, 150Kg of cyclohexane, 5.5Kg of catalyst p-toluenesulfonic acid, and a pair of polymerization inhibitors Hydroquinone 3.6Kg, then stir and heat, reflux reaction 10h, and constantly discharge the water that generates in the reaction system, so that the reaction is carried out to the direction that is conducive to generating product; Calculate the water amount to finish the reaction after reaching the theoretical value; Mixture is cooled to 30 ℃, add 500Kg mass concentration and be that 5% sodium hydroxide solution washes once, keep system and maintain neutral environment, divide and remove water phase, organic phase and middle layer are filtered together, then organic phase is washed with deionized water unti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com