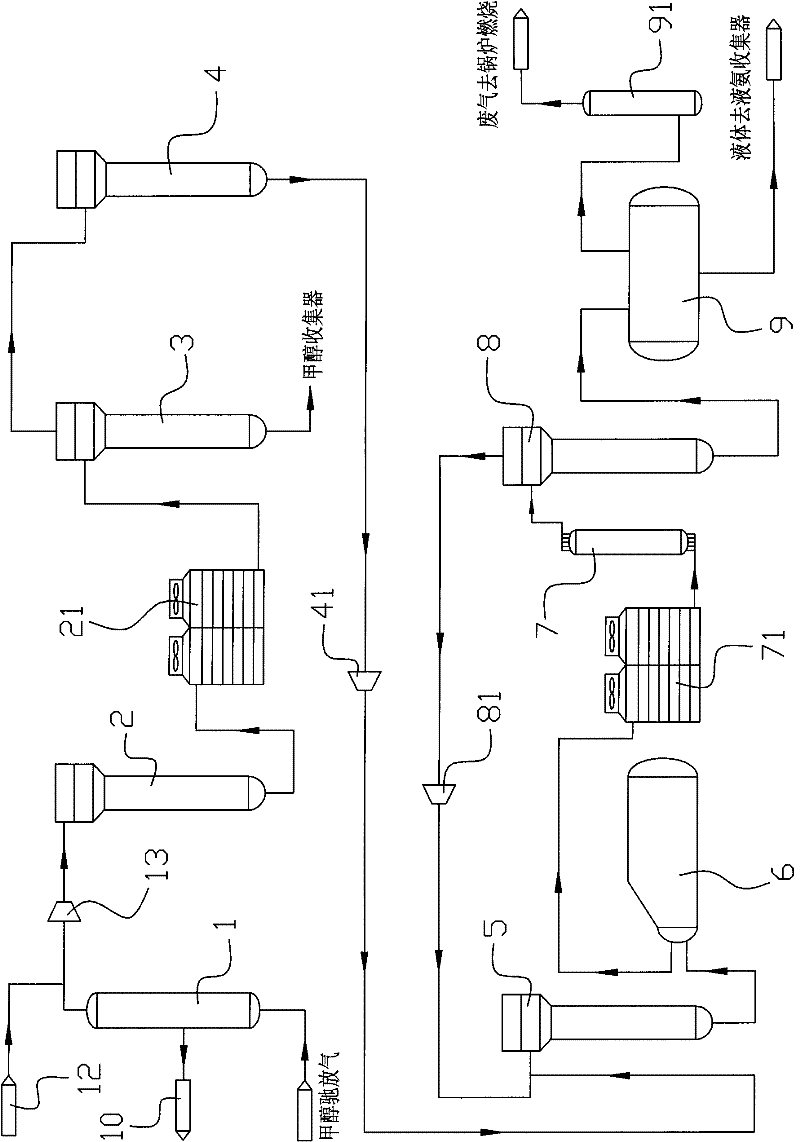

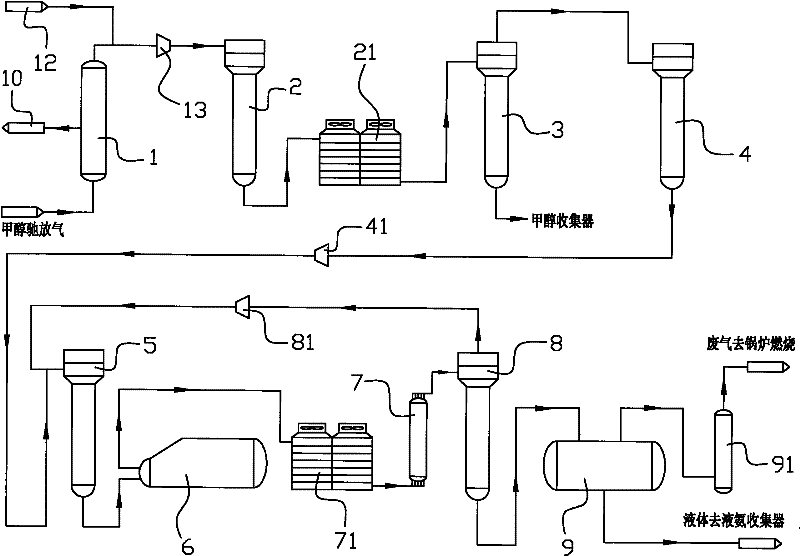

Apparatus for joint production of methanol and synthetic ammonia by using exhaust gas from methanol synthesis

A technology for methanol purge gas and combined production, which is applied in the preparation/separation of ammonia, preparation of organic compounds, chemical instruments and methods, etc., can solve the problems of waste of resources, increased production consumption, insufficient carbon elements, etc., to solve pollution problems. problems, improve the economic benefits of enterprises, and increase the effect of added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The coke output of a certain factory is 1.5 million tons / year, and the coke oven gas produced in the production process can produce 200,000 tons / year of methanol. Due to the high ratio of hydrogen to carbon in methanol synthesis gas, the purge gas produced in the process of methanol production is large, except for a small amount used as coking fuel, most of it is vented and burned. A new set of 80,000 tons of synthetic ammonia plant was launched, with a methanol discharge gas of 33,000Nm 3 / h, the gas composition is H 2 76.74% CH 4 1.18%N 2 9.75%CO6.59%CO 2 5.59% CmHn 2.1%, pressure 4.5MPa, temperature 35°C, decompression to 2.1MPa and then enter the decarburization section, the carbon dioxide gas produced by decarburization returns to the methanol synthesis unit after pressurization. The gases after decarburization mainly include hydrogen, nitrogen and a small amount of carbon monoxide, carbon dioxide and methane. In order to ensure the requirement of hydrogen-nit...

Embodiment 2

[0024] The coke output of a certain factory is 1.2 million tons per year, and the coke oven gas produced in the production process produces 150,000 tons of methanol per year. It is equipped with a 60,000-ton synthetic ammonia device and a 30,000-ton food carbon dioxide device. Methanol purge gas 26000Nm 3 / h, the gas composition is H 2 73.25%CH 4 1.38%N29.25%CO6.28%CO 25.86% CmHn 2.1%, gas pressure 4.2MPa, temperature 35°C, decompression to 2.0MPa and then enter the pressure swing adsorption decarburization section, the carbon dioxide gas produced by decarbonization is pressurized to produce 30,000 tons / year of food-grade carbon dioxide. The gas composition after decarburization is: 76.85% hydrogen, 9.73% nitrogen, and a small amount of carbon monoxide, carbon dioxide and methane. In order to ensure the requirement of 3:1 ratio of hydrogen to nitrogen in the production of synthetic ammonia, high-purity nitrogen (99.99% of the nitrogen comes from the air separation system) 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com