Silver nano superstructure array, and preparation method and application thereof

A superstructure and silver nanotechnology, which is applied in the field of chemical materials, can solve the problems of poor effective specific structure control and poor order control, and achieve the effect of enhancing photoelectric conversion efficiency and high positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] The silicon wafers in this embodiment were purchased from Beijing Zhongjing Keyi Technology Co., Ltd., the product name is monocrystalline silicon wafer, and the product number is P556359.

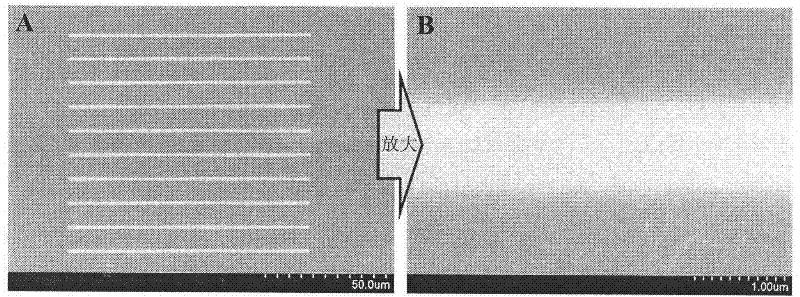

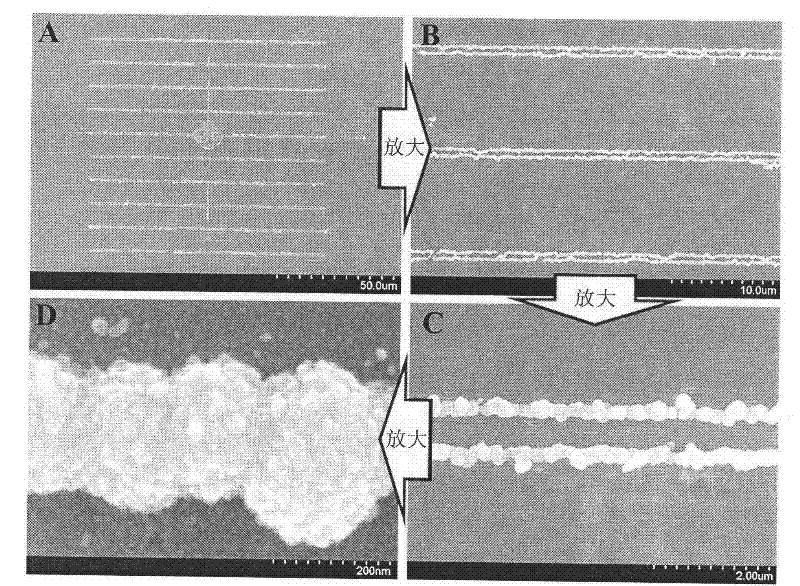

[0065] Silver nano-superstructure arrays on silicon wafer surface composed of one-dimensional necklace-like silver nano-superstructure lines preparation.

[0066] (1) Cut the commercial polished silicon wafer of P type 4 into small pieces of 1.5cm×1.5cm with a dicing machine.

[0067] (2) The cut silicon wafers were ultrasonically cleaned with acetone, ethanol and secondary water for 5 minutes in sequence, and then blown dry with nitrogen after removing surface pollutants.

[0068] (3) Glue the clean silicon wafers sequentially in the ultra-clean room according to the pre-designed line array pattern (the coating material is polymethyl methacrylate, and the coating amount is 1-2 μm thick). The silicon wafer is exposed under the SEM electron beam. During the exposure, the compute...

Embodiment 2

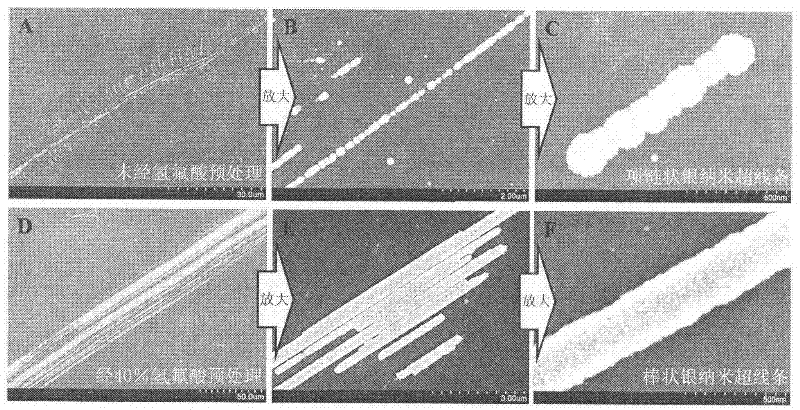

[0077] Fabrication of silver nanosuperstructure arrays on silicon wafer surface composed of one-dimensional rod-like silver nanosuperwires.

[0078] Step (1)-(8) is the same as embodiment 1

[0079] (9) immerse the patterned silicon wafer pretreated by electron beam exposure and reactive ion beam etching in hydrofluoric acid with a volume concentration of 40% for 1 hour and then immerse in the silver ion-cysteine complex solution, Then put them into a 37°C electric incubator and cultivate them for 2 days.

[0080] (10) Take out the cultured silicon chip, wash it repeatedly with secondary water to remove the residual solution on the surface, and then blow it dry with nitrogen to obtain a silver nano-superstructure array on the surface of the silicon chip composed of one-dimensional rod-shaped silver nano-superstructure lines.

[0081] Example 1 Steps (1)-(4) The surface of the silicon wafer after electron beam exposure and reactive ion beam etching surface patterning pretr...

Embodiment 3

[0083] SERS detection

[0084] (1) p-aminothiophenol (abbreviated as PATP in English) is dissolved in the mixed solvent of methanol and water with a volume ratio of 1:1 to form a concentration of 10 -10 M's solution.

[0085] (2) Dilute 100μL concentration to 10 -10 The PATP solution of M is added in the specially-made SERS sample groove, then the silicon wafer with the silver nanometer superstructure array that embodiment 1 prepares is immersed, carries out SERS signal collection (laser 633nm; Power about 2mW; Exposure time 10s), the result shows that this The PATP detection limit of silver nano-superstructure array on the surface of a silicon wafer can reach 10 -10 M.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com