Process for production of vaccines

A vaccine and toxin technology, applied in chemical instruments and methods, biochemical equipment and methods, pharmaceutical formulations, etc., can solve problems such as affecting the effectiveness of vaccines, costing, and loss of antigenic epitopes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1: Manufacture of Clostridium difficile vaccine

[0029] C. difficile samples are available from public collections such as the American Type Culture Center (ATCC), Manassas, VA, USA, numbers ATCC 9689, ATCC 43255. It was grown in the fermenter of BHI medium (brain heart infusion, Becton Dickinson, Heidelberg, Germany; see American Pharmaceutical Association, 1950, The national formulary, 9th edition, APA, Washington, D.C.) , fermented under anaerobic conditions at 37°C for 3 to 4 days. Two large cytotoxins, TcdA and TcdB, are released during the stable phase. At this time point, the culture was harvested and the bacteria were pelleted by centrifugation at 8000 xg for 10 minutes. The supernatant is used directly, or the toxin can be enriched by gel permeation chromatography (eg, on S300 Sephacryl), affinity chromatography, anion exchange chromatography and / or ultrafiltration. The reducing agent dithiothreitol is then added to the supernatant or toxin-enriched...

Embodiment 2

[0031] Embodiment 2: activity test

[0032] CHO cells (Chinese hamster ovary, e.g. DSMACC110, Deutsche Sammlungvon Mikroorganismen und Zellkulturen GmbH, Braunschweig, Germany) are inoculated in e.g. Ham's F10 medium containing e.g. 5% FCS (fetal calf serum) into 96- or 24-well microplates (100 μl per well), and incubated overnight at 37°C in a humid environment until they reached confluence. Rinse with Ringer's solution without divalent ions such as magnesium or calcium, then add 100 μl (96 well plate) or 400 μl (24 well plate) Ringer's solution without Mg and Ca into the well. Draw the vaccine preparation of 100 or 400 μ l embodiment 1 respectively with pipette subsequently, and each dilution series (10 -1 to 10 -8 ) to the well, and each sample was repeated twice. The BHI medium was treated in the same way as the vaccine preparation as a negative control. Untreated C. difficile supernatant was used as a positive control. The plates were incubated for 3 to 24 hours in a...

Embodiment 3

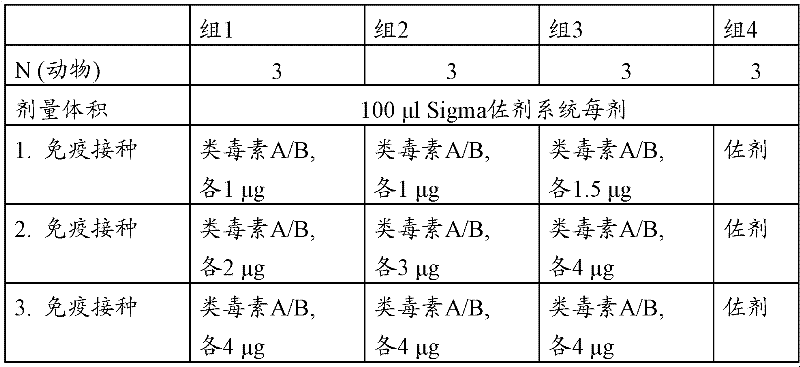

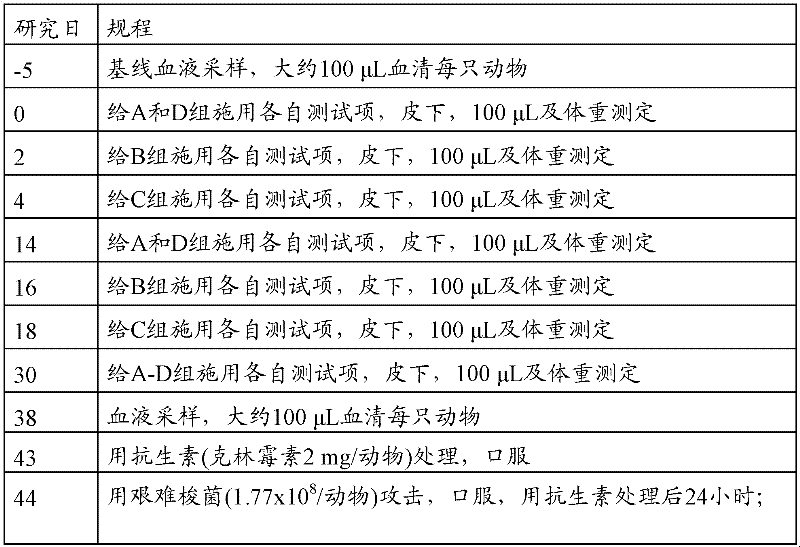

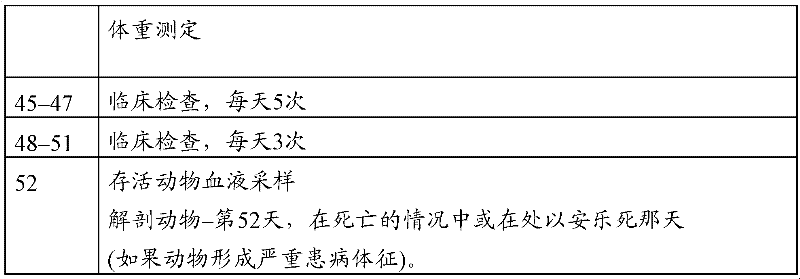

[0034] Example 3: Vaccination of Animals

[0035] The Syrian golden hamster can be used as a standardized animal model for C. difficile infection. Animals weighing 60 to 100 g were used in the experiments. The animals received vaccine formulations at different concentrations (1 to 100 μg) by intraperitoneal or subcutaneous injection. The vaccine was adjuvanted or contained complete Freund's adjuvant (1:1 with the vaccine formulation) or Ribi (emulsion of monophosphoryl lipid A and trehalose dicorynomycolate) as adjuvants. BHI medium treated with the same method as the vaccine was used as a negative control. Two weeks after the last vaccination, the animals received 10 to 100 mg / kg clindamycin intraperitoneally or orally. After 24 hours, each animal was inoculated with at least 10 4 Viable Clostridium difficile or 100 c.f.u (colony forming units). The protective efficacy of the vaccine is determined by clinical monitoring of diarrhea or mortality.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com