Catalysis technique for high-efficiency, moisture-resistance and room-temperature formaldehyde removal

A catalytic technology, a room temperature technology, is applied in the above-mentioned nanomaterials, nanomaterial preparation, and high-efficiency moisture-resistant room temperature removal of formaldehyde in the field of catalysis, which can solve the problems of expensive catalysts, and achieve excellent economy, good long-term performance, and excellent removal ability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

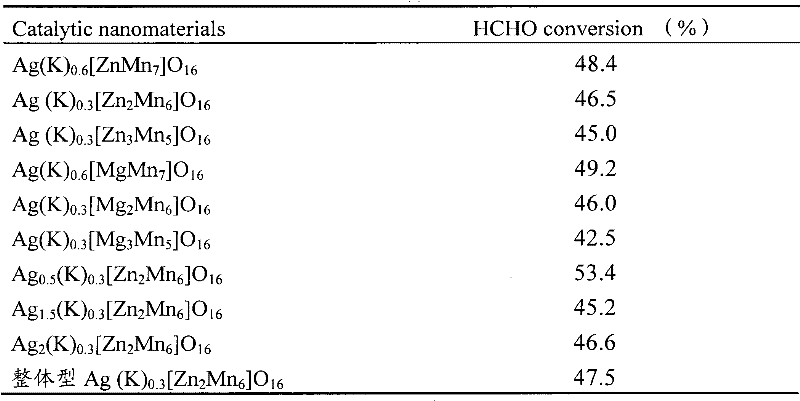

[0037] Hollandite-type MnO with Ag-containing channels 2 Matrix (Ag x (A) y [M z mn 8-z ]O 16 , A=K + , M=Zn 2+ or Mg 2+ ) preparation.

[0038] Powdered MnO 2 (P25), M salt (Zn(NO 3 ) 2 or Mg(NO 3 ) 2 ), template potassium nitrate (KNO 3 ) and organic matter P123 were mixed according to a certain amount, vigorously stirred and mixed evenly, dried at 100-150°C for 1-24h, then calcined at 900°C for 36h, washed after cooling, dried and calcined at 500°C for 24h to obtain skeleton-doped hollandite-type MnO 2 matrix.

[0039] The above hollandite type MnO 2 The matrix is added to a certain amount of aqueous solution to form a suspension. Add a certain concentration (≤25wt.%) of ammonia water to the silver nitrate solution (AgNO 3 ) to form silver ammonia (Ag(NH 3 ) 2 + ) solution. Under vigorous stirring, a certain concentration (≤30wt.%) of hydrogen peroxide (H 2 o 2 ) and silver ammonia (Ag(NH 3 ) 2 + ) solution was added dropwise to the above-mention...

Embodiment 2

[0043] Ag(K) 0.3 [Zn 2 mn 6 ]O 16 Preparation of monolithic catalytic materials. Weigh a certain amount of Ag(K) 0.3 [Zn 2 mn 6 ]O 16 , add a certain proportion of deionized water and 30% silica gel adhesive, stir at high speed for 10h, and obtain a certain concentration of doped Ag(K) 0.3 [Zn 2 mn 6 ]O 16 slurry. The doped Ag(K) 03 [Zn 2 mn 6 ]O 16 The slurry was coated on the pre-treated honeycomb ceramics, and fired at 500 °C for 12 hours to obtain doped Ag(K) 0.3 [Zn 2 mn 6 ]O 16 monolithic catalytic material. Recorded as "integral Ag(K) 0.3 [Zn 2 mn 6 ]O 16 ".

[0044] The formaldehyde performance test of monolithic catalytic materials was carried out on a fixed bed. The three-dimensional of monolithic catalyst is 150*150*40mm 3 , and then put it into a glass tube, at room temperature (20°C) and relative humidity of 50%, pass through a solution containing 5.0mg / m 3 For formaldehyde air, the wind speed is 1.5m / s. The air purifier uses FMNR infra...

Embodiment 3

[0046] doped Ag(K) 0.3 [Zn 2 mn 6 ]O 16 The matrix-loaded Pt was prepared by gas phase reduction method: the above-mentioned loaded Ag(K) 0.3 [Zn 2 mn 6 ]O 16 Monolithic material (prepared by claim 6) is impregnated in nitrosodiamine platinum (Pt(NH 3 ) 2 (NO 2 ) 2 ) or chloroplatinic acid (H 2 PtCl 6 ) in the mixed solution, baked at 300°C for 4h after drying, and then in H 2 Reduction at 300°C for 4 hours in the atmosphere, or irradiating with a certain 254nm UV for 36 hours. Prepared by liquid phase reduction method: loading Ag(K) 0.3 [Zn 2 mn 6 ]O 16 The monolithic material is impregnated in a certain concentration of AgNO 3 and Pt(NH 3 ) 2 (NO 2 ) 2 or H 2 PtCl 6 mixed solution, and then add the reducing agent NaBH 4 , reacted at room temperature for 4h, dried and baked at 300°C for 4h, recorded "Pt / Ag(K) 0.3 [Zn 2 mn 6 ]O 16 ". The content of the metal was analyzed by ICP, where Pt and doped Ag(K) 0.3 [Zn 2 mn 6 ]O 16 The matrix ratio is 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com