Amino-acid-containing biological compound fertilizer

A bio-compound fertilizer and amino acid technology, which is applied in the treatment of bio-organic parts, organic fertilizers, fertilization devices, etc., can solve the acute problems of landfill reconstruction and reuse, threats to human survival and health, and inability to find suitable sites, etc. problems, to achieve the effect of being conducive to sustainable development and utilization, preventing the occurrence of soil-borne diseases, and improving the environment of the production area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

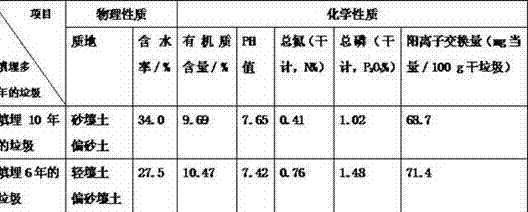

Image

Examples

Embodiment 1

[0032] Example 1: Amino acid-containing biological compound fertilizer includes the product prepared by the steps in the following order: A, manufacturing bio-organic fertilizer: raw materials used are: modified zeolite powder 5kg, brown sugar 0.8 kg, rice bran 10 kg, phosphate rock powder 8.5 kg, lignite fine The final 52 kg, chicken manure 23.7 kg. Mix the above raw materials evenly in proportion, compost, keep the temperature between 60-70°C on the first and second days, keep the temperature between 30-40°C on the third and fourth days, keep the normal temperature on the fifth and sixth days , and then get organic fertilizer.

[0033] B. Manufacture of amino acid-containing liquid fertilizer: 3 kg of enzyme bacteria, 90 kg of discarded vegetable leaves and 7 kg of organic fertilizer obtained in step A are prepared in proportion and put into the compost pond in the field, and the mouth of the compost pond is sealed with a plastic film Live and ferment for 13 days, when th...

Embodiment 2

[0037] Example 2: Amino acid-containing biological compound fertilizer comprises the product prepared by the steps in the following order: A, manufacturing bio-organic fertilizer: raw materials used are: modified zeolite powder 6kg, brown sugar 0.6 kg, rice bran 8.5 kg, phosphate rock powder 8 kg, lignite fine The final 50 kg, chicken manure 26.9 kg. The bio-organic fertilizer is prepared from the above raw materials according to the following method: grind the zeolite into a powder with a particle size of 180-220 mesh, ferment at 290° C. for 5-6 hours to obtain a modified zeolite powder, and set aside. Mix the above-mentioned modified zeolite powder with other ingredients evenly, compost, keep the temperature between 60-70°C on the first and second days, keep the temperature between 30-40°C on the third and fourth days, and keep the temperature between 30-40°C on the fifth and fourth days. Keep the normal temperature for six days, and then get bio-organic fertilizer.

[00...

Embodiment 3

[0042] Example 3: Amino acid-containing biological compound fertilizer comprises the product prepared by the steps in the following order: A, manufacturing bio-organic fertilizer: the raw materials used are: 8 kg of modified zeolite powder, 1 kg of brown sugar, 9 kg of rice bran, 9 kg of phosphate rock powder, fine lignite 45 kg at the end, 28 kg of duck manure. The bio-organic fertilizer is prepared from the above raw materials according to the following method: grind the zeolite into a powder with a particle size of 180-220 mesh, ferment at 300° C. for 5-6 hours to obtain a modified zeolite powder, and set aside. Mix the above-mentioned modified zeolite powder with other ingredients evenly, compost, keep the temperature between 60-70°C on the first and second days, keep the temperature between 30-40°C on the third and fourth days, and keep the temperature between 30-40°C on the fifth and fourth days. Keep the normal temperature for six days, and then get bio-organic fertil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com