Transparent acrylic acid silicone resin nano composite material and preparation method thereof

A technology of acrylic silicone resin and nano-composite material, which is applied in the field of transparent acrylic-silicon resin nano-composite material and its preparation, and can solve the problem of speeding up the transmission speed, no visible light transmittance and ultraviolet shielding effect of composite materials, and no media attention. Electrical properties and other issues, to achieve the effect of reducing interaction enthalpy, excellent UV shielding performance, and high visible light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

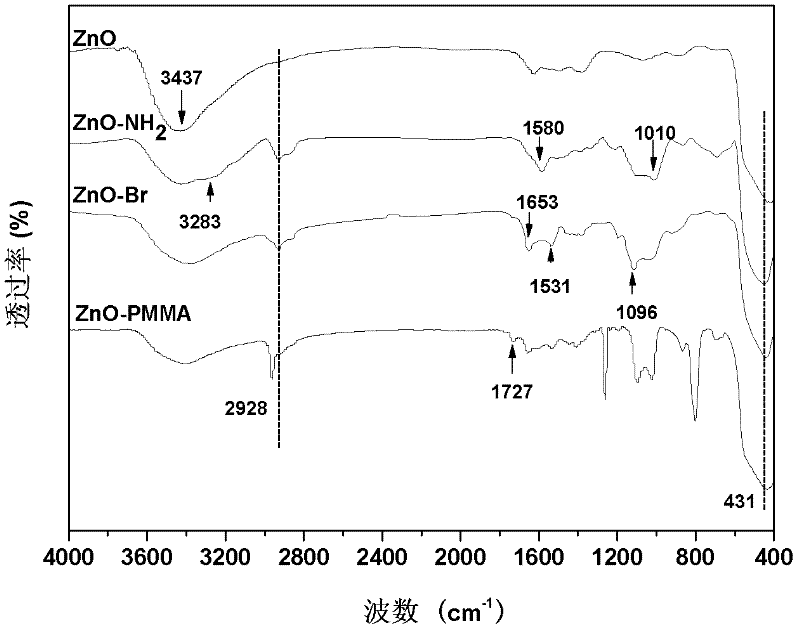

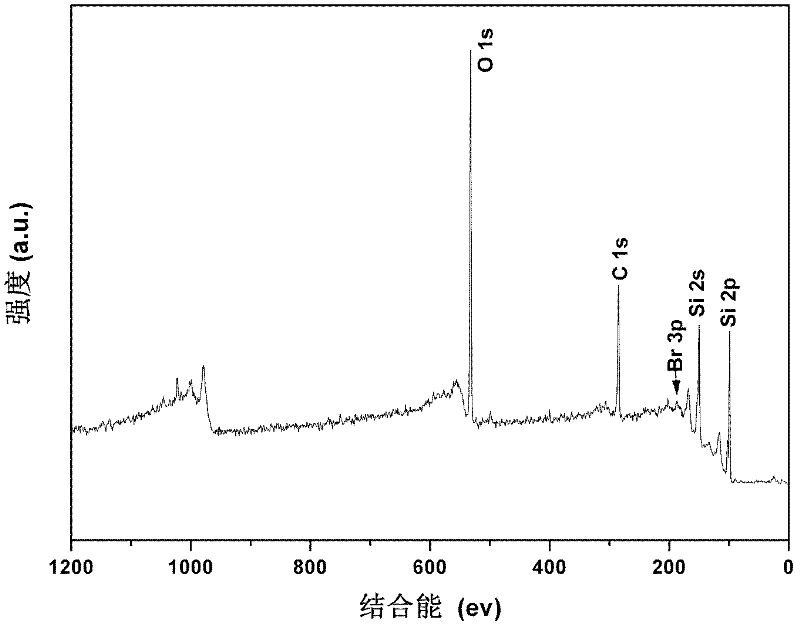

[0035] After mixing 3.6g of distilled water and 24.84g of γ-methacryloxypropyltrimethoxysilane evenly, add 0.04g of sodium hydroxide and 5ml of acetone at room temperature, and reflux at 50°C for 2h. Then tartaric acid equivalent to sodium hydroxide was added, filtered, vacuum-dried, and the solvent was evaporated to obtain transparent and viscous organosiloxane with methacryloyloxy as the terminal group.

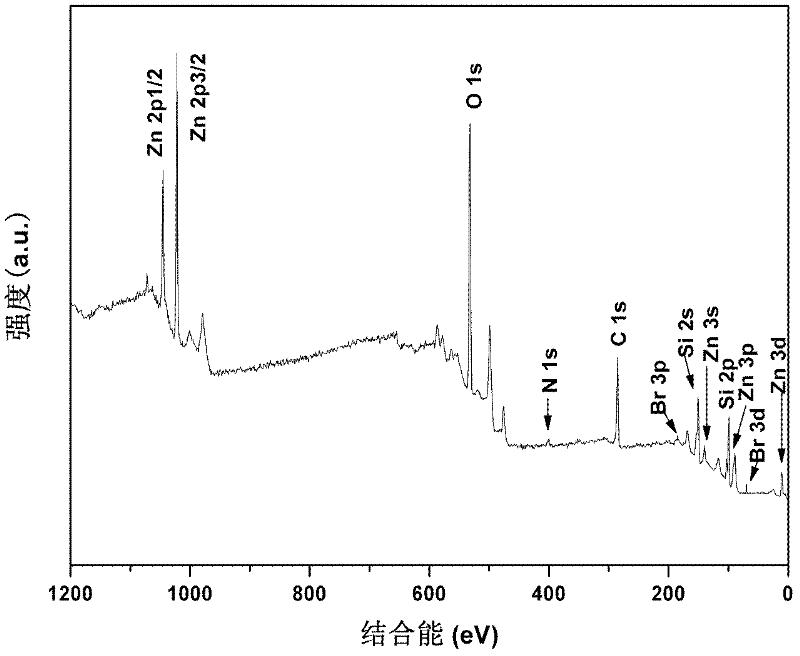

[0036] Take 2g of dried zinc oxide nanoparticles, mix with 100ml of toluene, 0.06g of γ-aminopropyltriethoxysilane ultrasonically, and then reflux and stir for 24h. centrifuged, washed and dried to obtain ZnO-NH 2 .

[0037] Take 1g of ZnO-NH prepared above 2 Mix with 100ml tetrahydrofuran ultrasonically, then add 0.97g triethylamine at 0°C, and slowly add 1.86g 2-bromoisobutyryl bromide dropwise to mix with it, continue to react for 1h, then react at room temperature for 24h, and centrifuge , and vacuum-dried to obtain ZnO-Br.

[0038] Take 0.5g of ZnO-Br obtained abov...

Embodiment 2

[0044] After mixing 3.6g of distilled water and 24.84g of γ-methacryloxypropyltrimethoxysilane evenly, add 0.04g of sodium hydroxide and 5ml of acetone at room temperature, and reflux at 50°C for 2h. Then tartaric acid equivalent to sodium hydroxide was added, filtered, vacuum-dried, and the solvent was evaporated to obtain transparent and viscous organosiloxane with methacryloyloxy as the terminal group.

[0045] Take 2g of dried zinc oxide nanoparticles, mix with 100ml of toluene, 0.06g of γ-aminopropyltriethoxysilane ultrasonically, and then reflux and stir for 24h. centrifuged, washed and dried to obtain ZnO-NH 2 .

[0046] Take 1g of ZnO-NH prepared above 2 Mix with 100ml tetrahydrofuran ultrasonically, then add 0.97g triethylamine at 0°C, and slowly add 1.86g 2-bromoisobutyryl bromide dropwise to mix with it, continue to react for 1h, then react at room temperature for 24h, and centrifuge , and vacuum-dried to obtain ZnO-Br.

[0047] Take 0.5g of ZnO-Br obtained abov...

Embodiment 3

[0062] After mixing 3.6g of distilled water and 24.84g of γ-methacryloxypropyltrimethoxysilane evenly, add 0.04g of sodium hydroxide and 5ml of acetone at room temperature, and reflux at 50°C for 2h. Then tartaric acid equivalent to sodium hydroxide was added, filtered, vacuum-dried, and the solvent was evaporated to obtain transparent and viscous organosiloxane with methacryloyloxy as the terminal group.

[0063] Take 2g of dried zinc oxide nanoparticles, mix with 100ml of toluene, 0.06g of γ-aminopropyltriethoxysilane ultrasonically, and then reflux and stir for 24h. centrifuged, washed and dried to obtain ZnO-NH 2 .

[0064] Take 1g of ZnO-NH prepared above 2 Mix with 100ml tetrahydrofuran ultrasonically, then add 0.97g triethylamine at 0°C, and slowly add 1.86g 2-bromoisobutyryl bromide dropwise to mix with it, continue to react for 30min, then react at room temperature for 24h, and centrifuge , and vacuum-dried to obtain ZnO-Br.

[0065] Take 0.5g of ZnO-Br obtained a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com