Ultraviolet avalanche photodetector with PIN inverted structure and preparation method thereof

A photodetector and ultraviolet avalanche technology, applied in the field of ultraviolet detectors, can solve the problems of complex process, difficult testing, large lattice and thermal mismatch, etc., to simplify the process, reduce the difficulty of testing, and improve the detection sensitivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below with reference to the accompanying drawings.

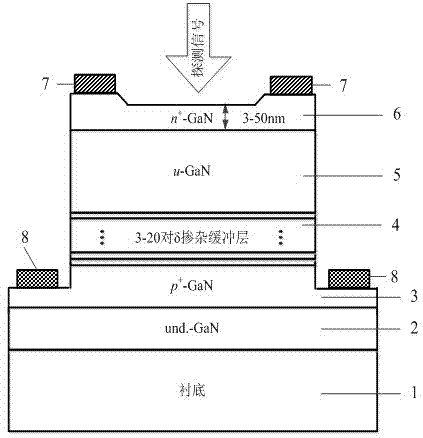

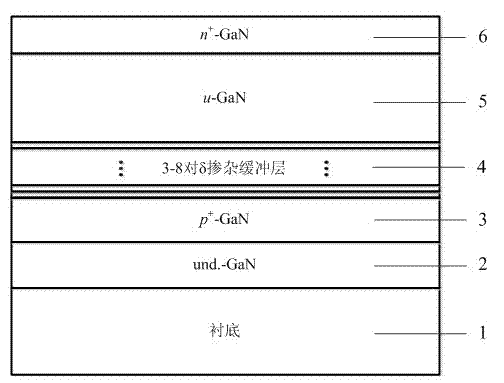

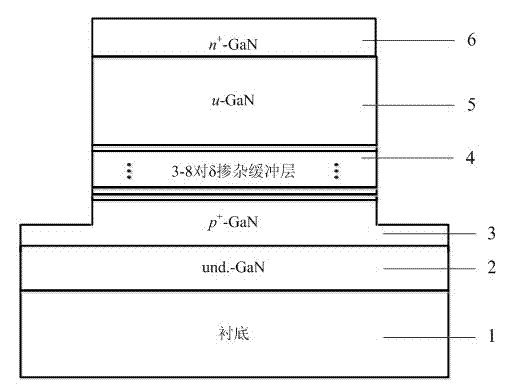

[0035] This example figure 1 A UV avalanche photodetector with a PIN inverted structure is presented, which includes: a sapphire substrate 1 and a low-temperature and high-temperature Ga N buffer layer 2, a p-type GaN layer 3, and a 3-8 pair of delta-doped buffer layer grown on it. GaN layer 4, non-doped or low-doped GaN active layer 5, n-type GaN layer 6; and n-type ohmic contact electrode 7 fabricated on n-type GaN, and p-type ohmic contact electrode 8 of p-type GaN . Taking advantage of the GaN material's characteristic of triggering holes in the avalanche process, the inverted PIN structure is adopted in the structural design. When the light signal is incident from the n-type layer, the holes are accelerated under the action of the avalanche electric field, which will maximize The gain path can greatly improve the avalanche gain of the device and suppress the dark n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com