Semi-covalent molecularly imprinted polymer used for selectivity separating phenols, preparation method thereof, and application thereof

A technology of imprinting polymers and covalent molecules, which is applied in the direction of material separation, material analysis, and other chemical processes, to achieve the effect of weakening peak broadening and tailing, good selectivity, and good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

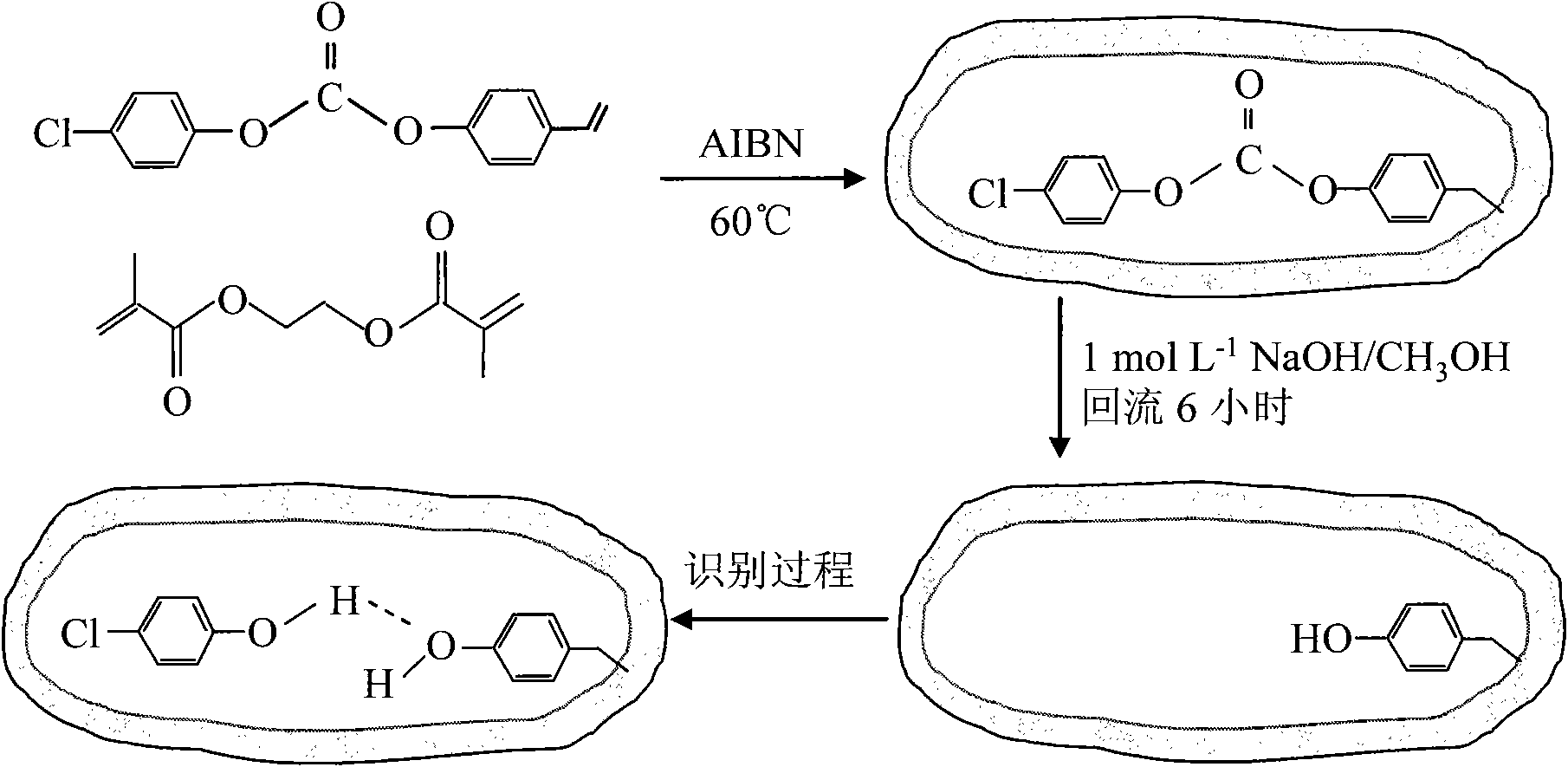

[0034] Preparation of template molecules 4-chlorophenyl(4-vinyl)phenyl carbonate and 4-methylphenyl(4-vinyl)phenyl carbonate.

[0035] Dissolve 16.6mmol of 4-vinylphenol in 60mL of dried tetrahydrofuran and 4mL of triethylamine solution, and add a small amount of 2,6-di-tert-butyl-4-methylphenol, and put the above solution in the circle The bottom flask was placed in an ice bath, and a solution of 16.6 mmol 4-chlorobenzochloroformate in tetrahydrofuran (40 mL) was gradually added dropwise for about 2 hours, and then the mixed solution was stirred overnight at room temperature. After the reaction was completed, it was filtered, and the supernatant was distilled under reduced pressure to obtain a crude product. Recrystallization from methanol gave colorless flaky crystals.

[0036] Dissolve 16.6mmol of 4-vinylphenol in 60mL of dried tetrahydrofuran and 4mL of triethylamine solution, and add a small amount of 2,6-di-tert-butyl-4-methylphenol, and put the above solution in the ci...

Embodiment 2

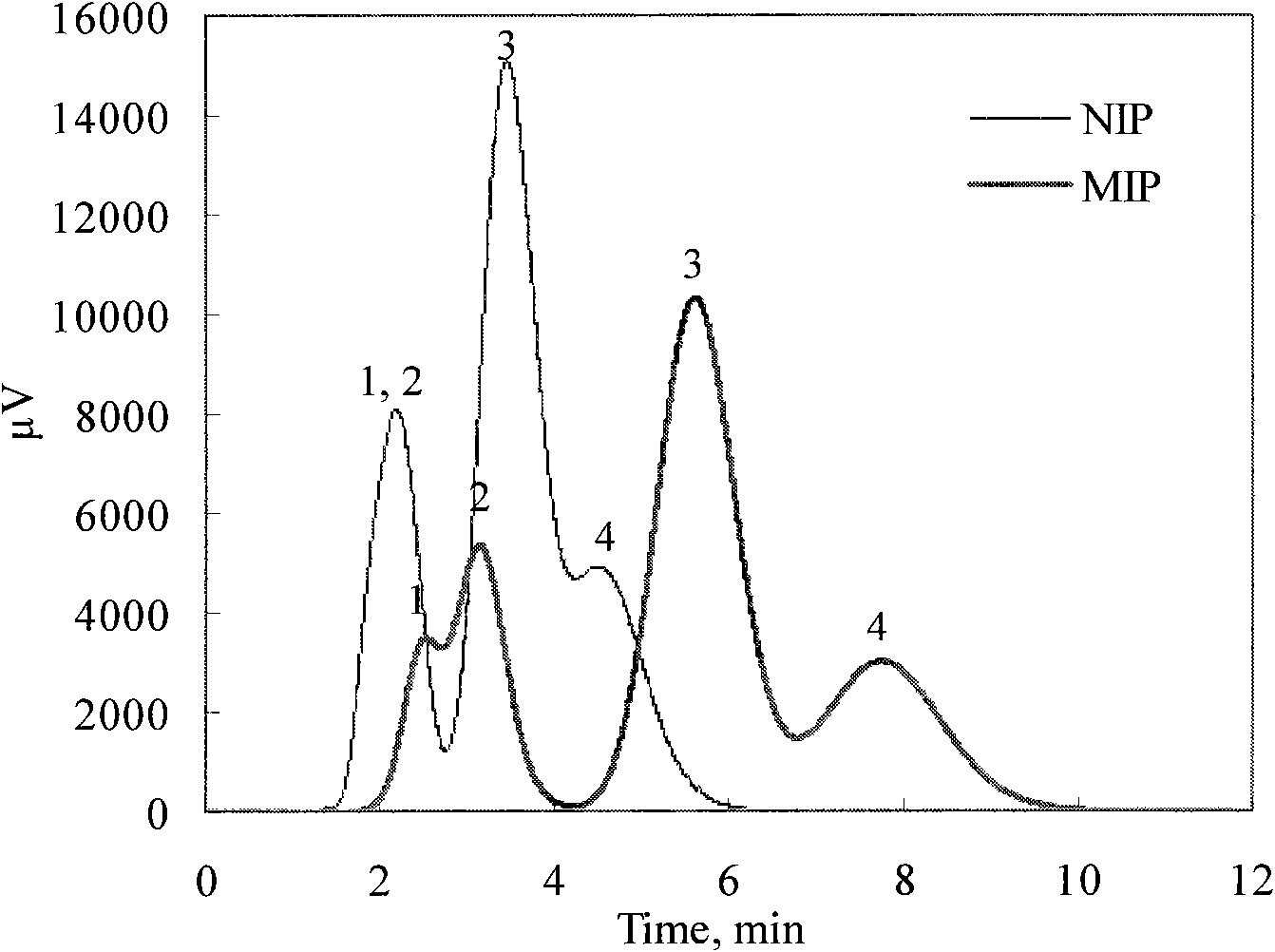

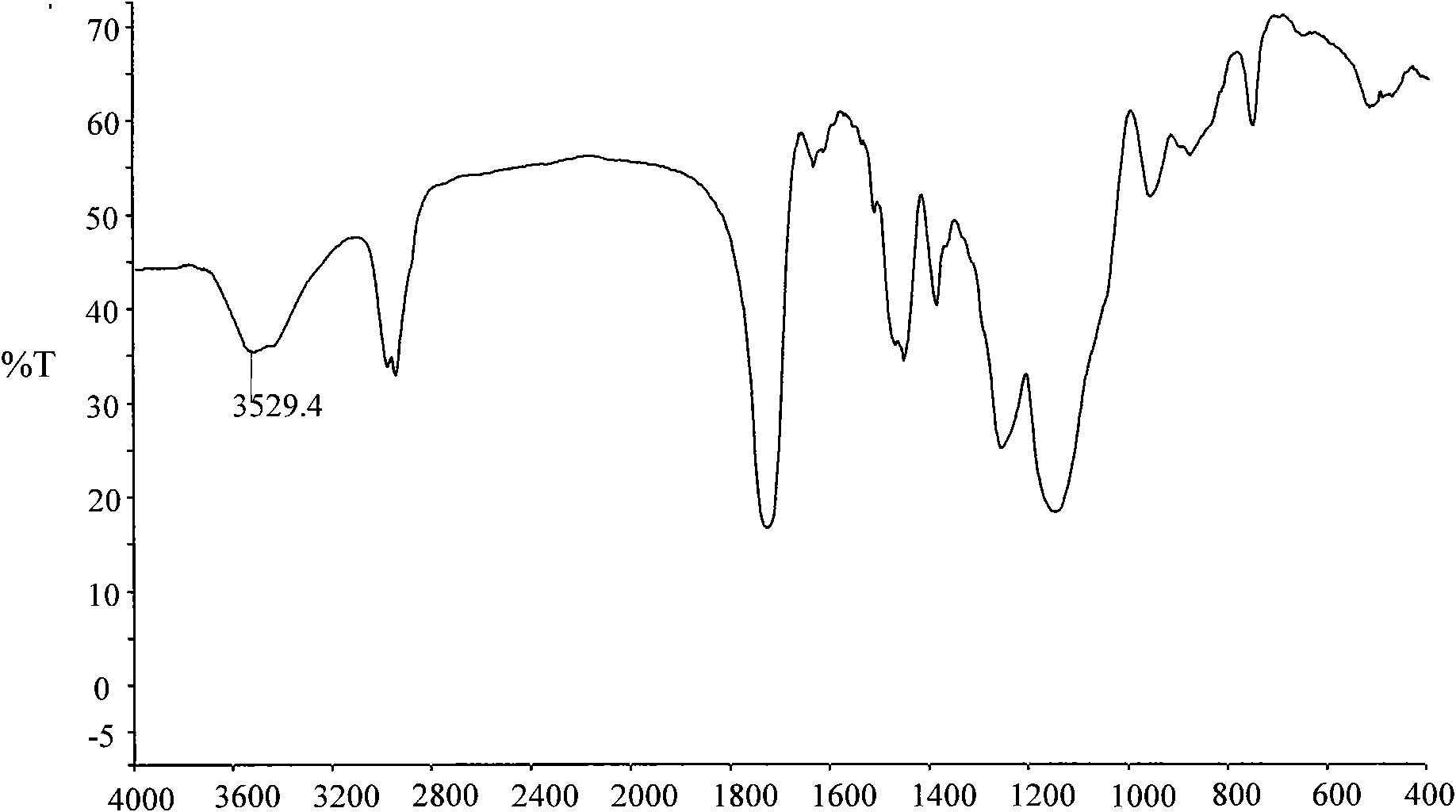

[0038] Dissolve 1 mmol of template molecule 4-chlorophenyl (4-vinyl) phenyl carbonate into a chloroform solution containing 20 mmol of crosslinker ethylene glycol dimethacrylate and 0.04 g of initiator azobisisobutyronitrile Prepare a mixed solution in an ice bath, put the mixed solution in an ice bath and ultrasonically mix for 10-15 minutes, pass nitrogen for 10 minutes to remove oxygen in the system, seal it and place it at 60°C for 24 hours. The white massive polymer formed by the reaction is crushed and ground, and sieved to obtain a polymer with a particle size of 45-63 μm. The obtained polymer adopts 1mol L -1 Sodium hydroxide methanol solution was hydrolyzed for 6 hours, washed with dilute hydrochloric acid to neutrality, washed with water and methanol in turn, then suction filtered to dryness, and then methanol acetic acid (9:1, v / v) and methanol were used as extraction solvents for extraction. The template molecules and interfering substances were removed by extract...

Embodiment 3

[0043] Dissolve 1 mmol of template molecule 4-methylphenyl(4-vinyl)phenyl carbonate into chloroform containing 20 mmol of crosslinker ethylene glycol dimethacrylate and 0.04 g of initiator azobisisobutyronitrile Prepare a mixed solution from the solution, place the mixed solution in an ice bath for 10-15 minutes and mix it with ultrasound, pass nitrogen for 10 minutes to remove oxygen in the system, seal it and place it at 60°C for 24 hours of reaction. The white massive polymer formed by the reaction is crushed and ground, and sieved to obtain a polymer with a particle size of 45-63 μm. The obtained polymer adopts 1mol L -1 Sodium hydroxide methanol solution was hydrolyzed for 6 hours, washed with dilute hydrochloric acid to neutrality, washed with water and methanol in turn, then suction filtered to dryness, and then methanol acetic acid (9:1, v / v) and methanol were used as extraction solvents for extraction. The template molecules and interfering substances were removed by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com