Alginate hydrogel microcarrier and preparation method thereof

An alginate and hydrogel technology, applied in bone/connective tissue cells, animal cells, vertebrate cells, etc., can solve problems such as adverse effects on karyotype stability of stem cells, effects on cell yield, and dangers of clinical use, etc. Achieve the effects of good cell compatibility, abundant raw material sources, and good mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

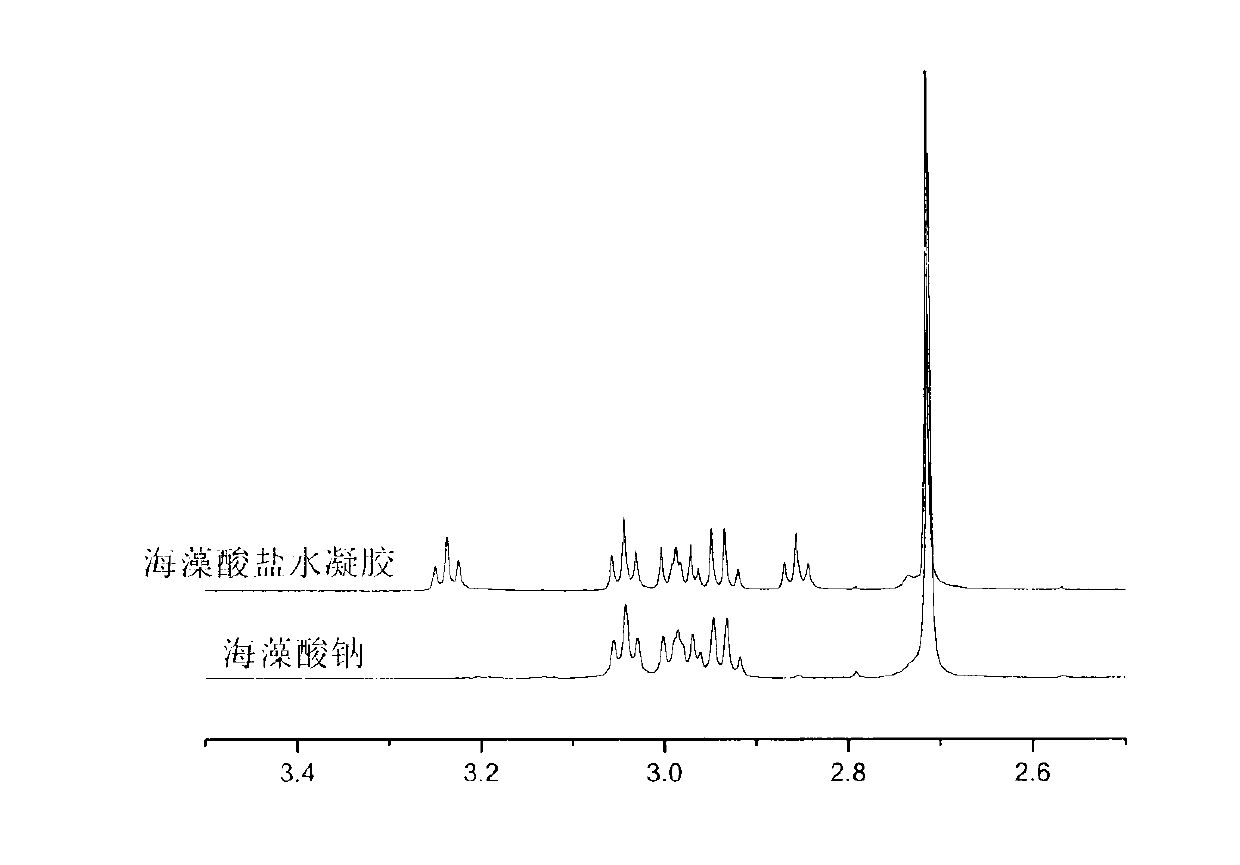

[0022] (1) Weigh 0.45 g of sodium alginate and add it to 10 mL of phosphate buffer solution with a pH of 5, and stir at room temperature until the sodium alginate is completely dissolved. Take 2g of sodium alginate solution, add 0.6g of EDC, and stir at 4°C for 30min.

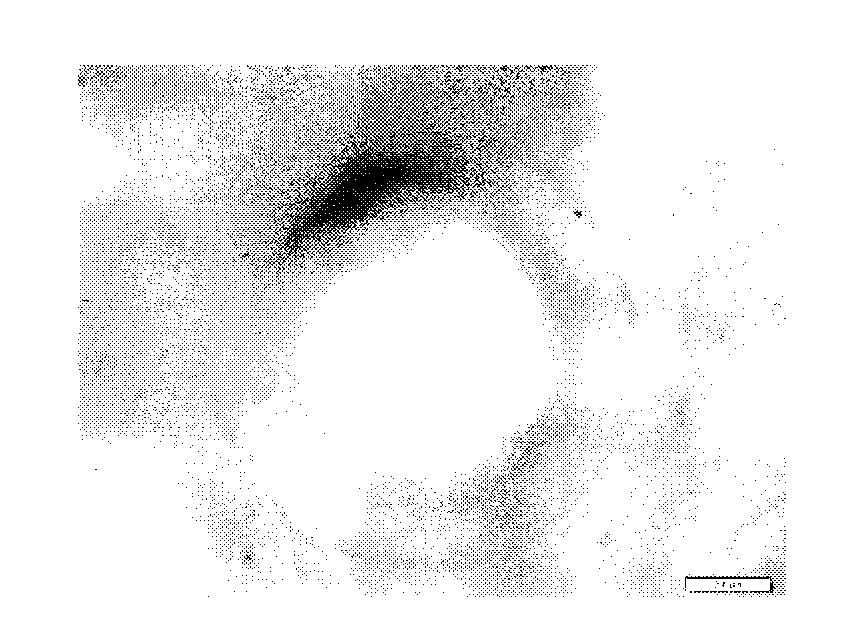

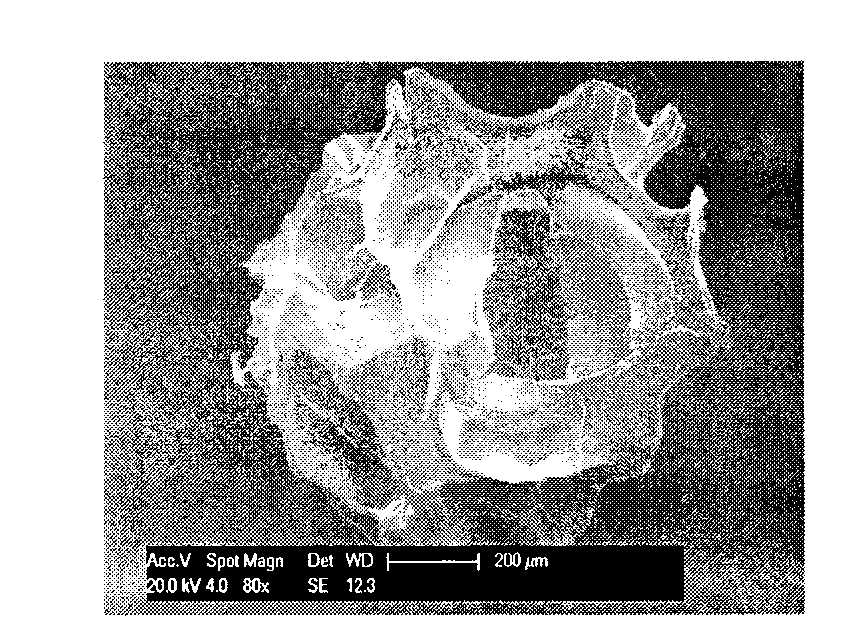

[0023] (2) Add 5 g of peanut oil and 0.25 g of Tween 80 aqueous solution with a mass concentration of 25% to the above solution, and stir at room temperature until a uniform suspension is formed. Then 1.5 ml of cystamine aqueous solution with a mass concentration of 37% was added, and the reaction was performed under constant temperature magnetic stirring at 40° C. and 500 rpm for 1 h. The product was suction filtered and washed with absolute ethanol at the same time to obtain alginate hydrogel microcarriers.

[0024] (3) Soak the alginate hydrogel microcarrier that step (2) obtains in the 20ml chitosan solution that the relative molecular mass is 5k, mass concentration is 0.3% for 5h, then in the 50ml phospha...

Embodiment 2

[0028] The raw materials and preparation method are similar to those in Example 1, except that the amount of sodium alginate is changed from 4.5g to 0.6g, and the prepared 0.1g alginate hydrogel microcarrier is 10ml, 20mmol / L at 37°C. The degradation time in cysteine solution is 25-28 hours.

Embodiment 3

[0030] The raw materials and preparation method are similar to Example 2, except that the amount of Tween 80 aqueous solution added is changed from 0.25g to 0.37g, and the prepared 0.1g alginate hydrogel microcarrier is 10ml, 20mmol at 37°C / L cysteine solution degradation time is 25 ~ 28h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com