Separation and purification method and immobilization method of papain, and product thereof

A papain, separation and purification technology, applied in the direction of immobilized enzymes, biochemical equipment and methods, enzymes, etc., can solve problems such as many steps, large impact on enzyme activity, and increased enzyme ash content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

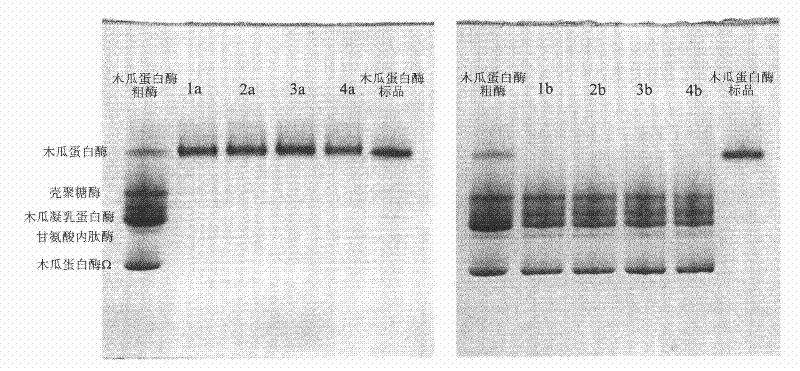

[0069] 1. Dissolve 40g papaya milk in 100ml 50mM cysteine solution (containing 5mM EDTA, pH 6.5) at 4°C, centrifuge (20,000×g, 4°C, 15min) to remove insoluble matter, and measure the supernatant protein concentration (measured by conventional Coomassie brilliant blue staining method), the protein concentration of the supernatant is adjusted to 10 mg / ml with 50 mM cysteine solution, and then the pH of the solution is adjusted to 6.5 (adjusted with 6M NaOH or HCl solution), which is the initial crude enzyme solution; meanwhile, configure 40% polyethylene glycol 2000 solution; configure 40% (w / w) ammonium sulfate solution, and adjust the pH to 6.5;

[0070] At 20°C, the initial crude enzyme solution, polyethylene glycol solution, ammonium sulfate solution and deionized water were mixed and dissolved together, wherein the mass percentage of the initial crude enzyme solution was 40%, and the mass percent of polyethylene glycol 2000 The percentage content is 30%, the mass percen...

Embodiment 2

[0075] At 4°C, 30g of papaya slurry was dissolved in 200ml of 25mM cysteine solution (containing 3mM EDTA, pH 6.0), centrifuged (20,000×g, 4°C, 15min) to remove insoluble matter, and the supernatant protein concentration was measured with 25mM cysteine solution to adjust the protein concentration of the supernatant to 10mg / ml, and then adjust the pH of the solution to 6.0 (adjusted by 6M NaOH or HCl solution), which is the initial crude enzyme solution; configure 40% polyethylene glycol 4000 solution; Simultaneously, configure 40% (w / w) sodium sulfate solution, adjust pH to be 6.0;

[0076]At 20°C, the initial crude enzyme solution, polyethylene glycol solution, sodium sulfate solution and deionized water were mixed and dissolved together, wherein the mass percentage of the initial crude enzyme solution was 35%, and the mass percent of polyethylene glycol 4000 The percentage content is 25%, the mass percentage content of sodium sulfate is 19%, and the mass percentage conte...

Embodiment 3

[0079] At 4°C, 20g of papaya powder was dissolved in 100ml of 30mM cysteine solution (containing 0.5mM EDTA, pH 5.8), centrifuged (20,000×g, 4°C, 15min) to remove insoluble matter, and the supernatant protein concentration was measured. Use 30mM cysteine solution to adjust the protein concentration of the supernatant to 15mg / ml, and then adjust the pH of the solution to 5.8 (adjusted by 6M NaOH or HCl solution), which is the initial crude enzyme solution; meanwhile, configure 40% polyethylene glycol 6000 solution; 40% (w / w) phosphate solution at pH 5.8 from 40% (w / w) K 2 HPO 4 and 40% (w / w) NaH 2 PO 4 Prepared.

[0080] At 20°C, the initial crude enzyme solution, polyethylene glycol solution, phosphate solution and deionized water were mixed and dissolved together, wherein the mass percentage of the initial crude enzyme solution was 30%, and the mass percent of polyethylene glycol 6000 The percentage content is 18%, the mass percentage content of phosphate is 10%, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com