Preparation method of amino functionalized micron gold and anion exchange resin composite material

A technology of amino functionalization and resin exchange, which is applied in anion exchange, ion exchange, chemical instruments and methods, etc. It can solve the problems of no clear public report on extraction technology, shortened service life, difficult resin regeneration, etc., and achieve high yield High, strong anti-pollution ability, easy regeneration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

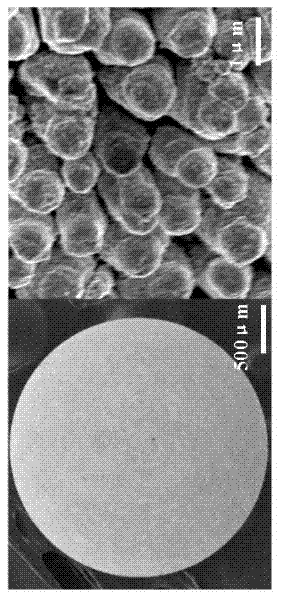

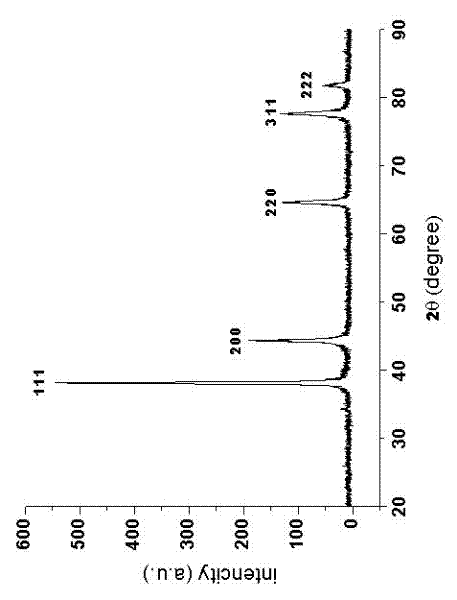

[0018] Dissolve 1 g of chloroauric acid in 45 g of deionized water, then put 8 g of hydroxyl type 201×7 strong basic anion exchange resin into standstill for 24 hours, take out the resin and wash it repeatedly with deionized water until neutral pH=7; Fully dissolve 6 g of sodium in 50 g of deionized water, then put the resin in, control the temperature at 25 ° C for 11 hours, take out the resin, wash it alternately with 100 g of deionized water and 50 g of absolute ethanol for 5 times, and wash it with 11 After natural soaking in g aminoethanethiol for 5 hours, the resin was taken out and washed (5 times) with absolute ethanol (50 g) to obtain the composite material of amino-functionalized micron gold and strongly basic anion exchange resin. figure 1 It is the field emission scanning electron micrograph of the obtained composite material, as can be seen from the figure, there are gold particles with a size in the micron range on the resin surface; figure 2 It is the X-ray dif...

Embodiment 2

[0020] Take 1.5 g of potassium chloroaurate and dissolve it in 40 g of deionized water, then put 6 g of D201 strongly basic anion exchange resin and let it stand for 24 hours, then take out the resin and wash it repeatedly with deionized water until neutral pH=7; take hydrazine hydrate 6 g fully dissolved in 50 g of deionized water, then put the resin in, and react at a controlled temperature of 15°C for 10.5 hours, then take out the resin, wash it alternately with 100 g of deionized water and 50 g of absolute ethanol for 5 times, and wash it with 11 g of amino After naturally soaking in thiophenol for 8 hours, the resin was taken out and washed (5 times) with absolute ethanol (50 g) to obtain the composite material of amino-functionalized micron gold and strongly basic anion exchange resin.

Embodiment 3

[0022] Take 2 g of sodium chloroaurate and dissolve it in 50 g of deionized water, then put 10 g of 201×2 strong basic anion exchange resin into it and let it stand for 24 hours, then take out the resin and wash it repeatedly with deionized water until neutral pH=7; Dissolve 3 g of ethylene glycol (average molecular weight 12,000) in 50 g of deionized water, then put the resin in, control the temperature at 15°C and react for 10.5 hours, take out the resin, and alternately use 100 g of deionized water and 50 g of absolute ethanol After washing 5 times, soak naturally with 11 g aminothiophenol for 8 hours, take out the resin and wash it (5 times) with absolute ethanol (50 g) to obtain the product amino-functionalized micron gold and strong basic anion exchange resin composite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com