Treatment method of exhaust gas from ultrapure ammonia purification device

A purification device and exhaust gas treatment technology, applied in chemical instruments and methods, separation methods, and dispersed particle separation, etc., can solve problems such as high ammonia content, high cost, and non-compliance with emission standards, so as to reduce production costs and improve production efficiency , the effect of saving the consumption of auxiliary materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

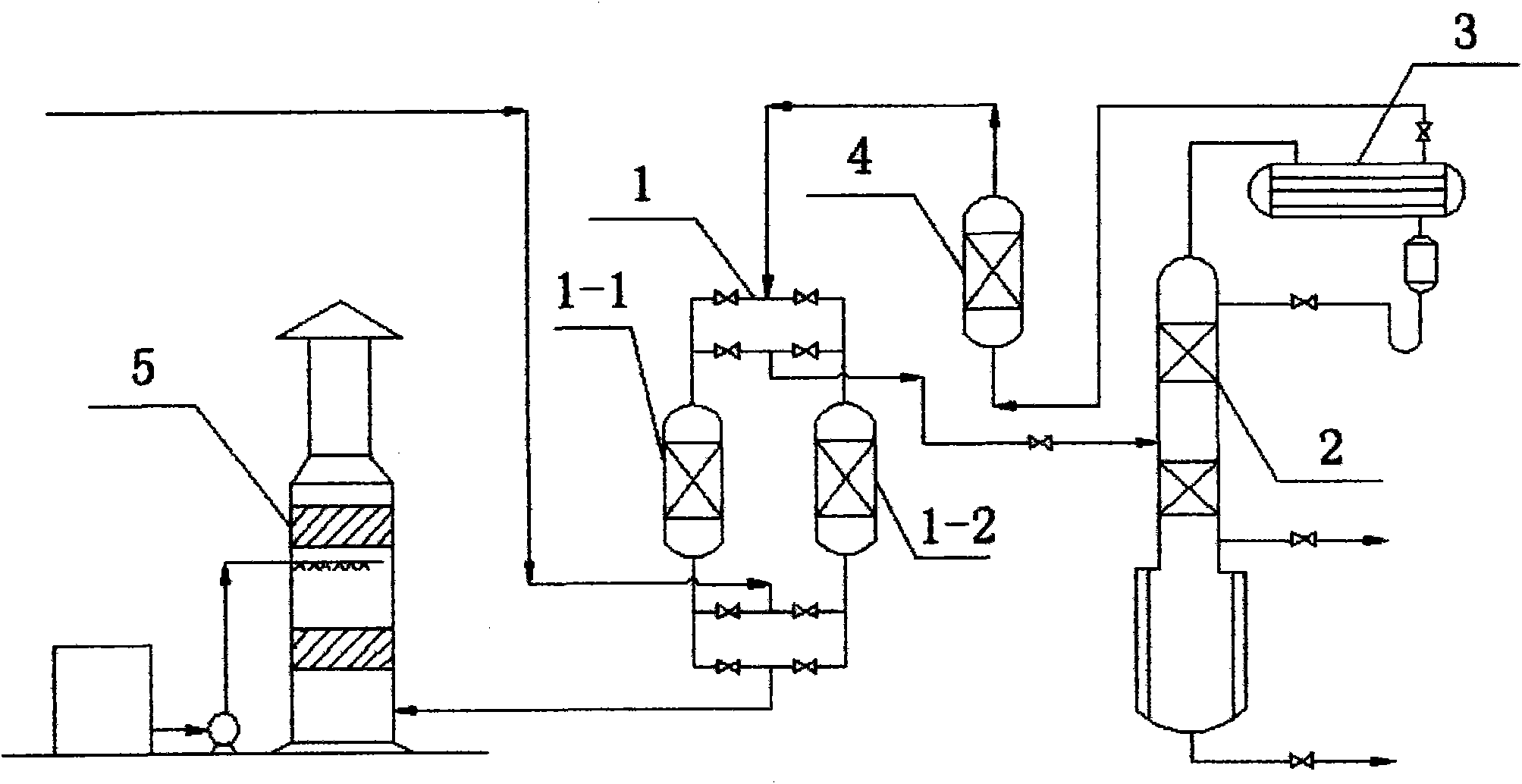

[0020] Taking the ammonia purification unit with an annual output of 500 tons of ultra-pure ammonia as an example, the consumption of raw material liquid ammonia is 65kg / h, and the amount of light component waste gas in the rectification tower is 2-4Nm 3 / h or so, the ammonia decomposition furnace contains 10kg of nickel catalyst, the furnace heating temperature is 850°C, and the hydrogen gas is 3-6Nm through the ammonia decomposition furnace 3 / h and nitrogen 1~2Nm 3 / h. It can be used as the regeneration gas of the catalytic adsorption system of the ammonia purification unit to ensure the purification effect of ammonia.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com