A method for large-scale production of potassium titanate by utilizing ore-grade titanium-containing compounds

A technology of titanium compounds and potassium titanate, which is applied in the fields of titanium compounds, chemical instruments and methods, and inorganic chemistry, can solve the problems of complicated production procedures, high raw material costs, and difficulty in large-scale production, and reduce alkaline corrosion loss , reduce calcination time, reduce the effect of calcination temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

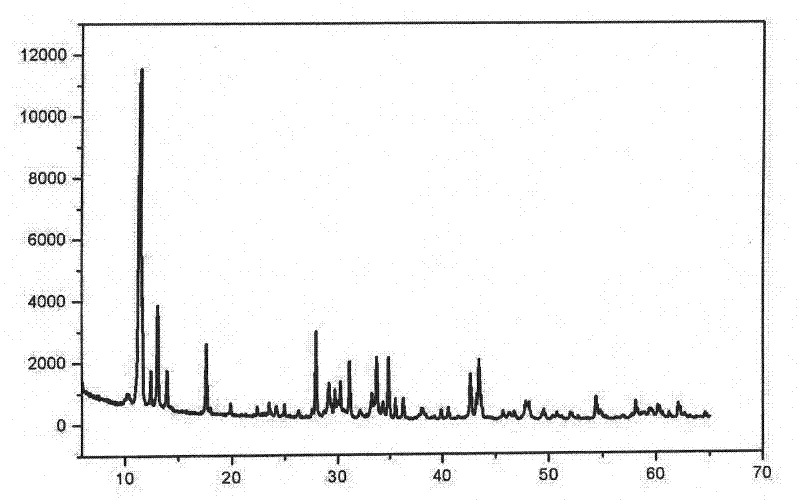

[0062] The crystalline rutile ore powder and potassium carbonate are TiO 2 And K 2 Based on O, according to the molar ratio of TiO 2 : K 2 O=5.5:1, fully mix the above two raw materials, add an appropriate amount of water during the mixing process, and the amount of water added to facilitate subsequent molding; then use a mold to press the above mixture into a three-dimensional channel structure with a height of 8cm, A cylindrical shape with a diameter of 10cm, the channel direction is parallel to the height direction, the channel diameter is 8mm, and the hole-to-hole spacing is 1cm; the above-mentioned cylindrical blank is heated to 1150℃ in a microwave shuttle kiln for 2 hours, and then cooled to 800 with the furnace After ℃, air-cooled to room temperature; the calcined product is crushed to 150 mesh with Raymond mill, and the product obtained is powdered potassium titanate. After X-ray diffraction analysis (such as figure 1 Shown) shows that the resulting product is potassium...

Embodiment 2

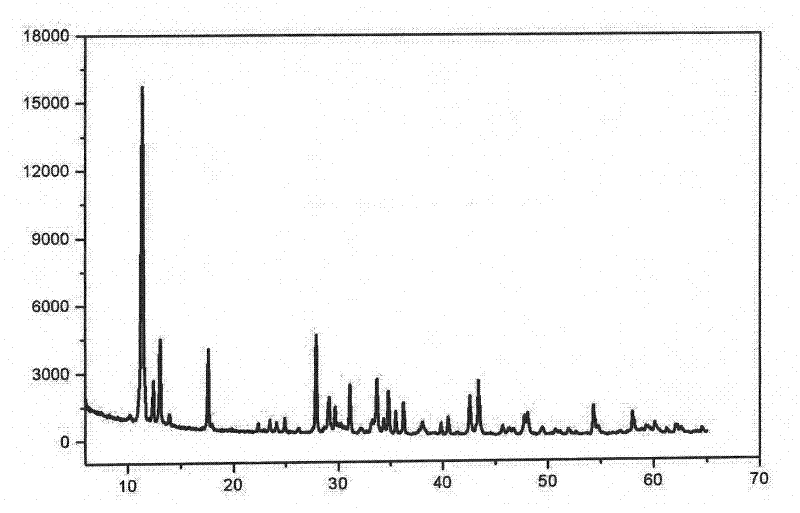

[0064] Amorphous titanium slag and potassium carbonate are TiO 2 And K 2 Based on O, according to the molar ratio of TiO 2 : K 2 O=5:1, fully mix the above two raw materials, add an appropriate amount of water during the mixing process, and the amount of water added to facilitate subsequent molding; then use a mold to press the above mixture into a three-dimensional channel structure with a height of 8cm, A cylindrical shape with a diameter of 10cm, the channel direction is parallel to the height direction, the channel diameter is 8mm, and the hole-to-hole spacing is 1cm; the above cylindrical blank is heated in a microwave shuttle kiln to 1050°C for 2 hours, and then cooled to 800 with the furnace After ℃, air-cooled to room temperature; the calcined product is crushed to 150 mesh with Raymond mill, and the product obtained is powdered potassium titanate. After X-ray diffraction analysis (such as image 3 Shown) shows that the resulting product is potassium hexatitanate (K 2 Ti...

Embodiment 3

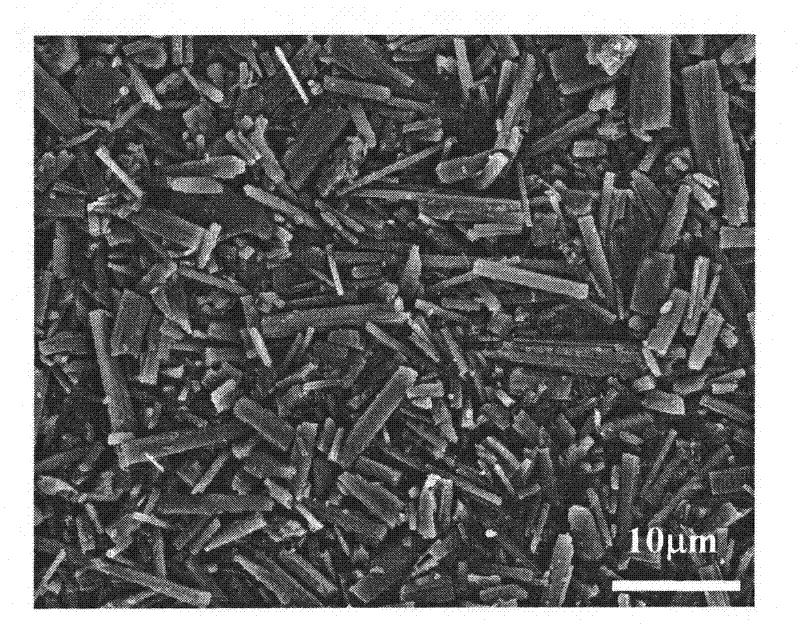

[0066] The crystalline anatase ore powder and potassium carbonate are TiO 2 And K 2 Based on O, according to the molar ratio of TiO 2 : K 2 O=4:1, fully mix the above two raw materials, add an appropriate amount of water during the mixing process, and the amount of water added to facilitate subsequent molding; then use a mold to press the above mixture into 10cm×10cm with a three-dimensional channel structure ×8cm rectangular parallelepiped, the channel direction is parallel to the height direction, the channel diameter is 1cm, and the hole-to-hole spacing is 1cm; the above cuboid blank is heated to 1050℃ in a microwave-assisted electric heating shuttle kiln, kept for 2 hours, and then cooled with the furnace After reaching 800°C, air-cooled to room temperature; the calcined product was pulverized to 100 mesh with a Raymond mill, then washed with water, stirred, filtered, and finally heat treated at 600°C for 5 hours. The resulting product was powdered potassium titanate. X-ray ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com