Zinc-nickel battery negative electrode active material, cable-stayed mesh negative electrode substrate, negative electrode and preparation method thereof

A negative electrode active material, zinc-nickel battery technology, applied in the direction of electrode manufacturing, battery electrodes, nickel storage batteries, etc., can solve the problems of increasing battery production cost and preparation difficulty, battery performance degradation, easy introduction of impurities, etc., to achieve inhibition of negative electrode deformation and Migration of negative electrode active material, low battery internal resistance, and the effect of avoiding failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0108] The present invention also provides a method for preparing a negative electrode of a zinc-nickel battery, comprising the following steps:

[0109] Al 2 o 3 pretreatment in the glue solution, the Al 2 o 3 Glue includes Al 2 o 3 , polyvinyl alcohol and water;

[0110] Coating the negative electrode active material composition described in the above technical solution on the pretreated negative electrode substrate, drying and rolling, and then shearing along the symmetry axis of the pretreated two sides of the negative electrode substrate to obtain a negative electrode semi-finished product ;

[0111] After immersing the symmetrical plane of the cut surface of the negative electrode semi-finished product in the glue solution to obtain the negative electrode of the zinc-nickel battery, the glue solution includes Al 2 o 3 , MgO, polyvinylidene fluoride emulsion, styrene-butadiene rubber emulsion, polyvinyl alcohol and water.

[0112] First, put the opposite sides of...

Embodiment 1

[0141] Example 1 Preparation of negative electrode active material slurry for zinc-nickel battery

[0142] First, heat the water bath to 60°C, add PVA and HPMC according to the mass ratio of water, PVA, and HPMC in a ratio of 93:4.5:2.5, and stir for 4 hours to obtain an adhesive;

[0143] Add 0.12g of nylon short fibers to 29g of binder, stir for 45min; continue to add 7.3g of Zn, stir for 15min; continue to add 5.91g of calcium hydroxide, zinc hydroxide and water with a mass ratio of 1:2:2, and stir for 3min; Continue to add 0.008gIn(OH) 2 , stirred for 30min; continue to add 1.35gBi 2 o 3 , stirred for 5min; continue to add 6.1g mass concentration of 60% polytetrafluoroethylene (PTFE) emulsion, stir for 5min; continue to add 0.0372g sodium dodecylbenzenesulfonate (SDBS), stir for 5min; continue to add 0.19gNa 2 HPO 4 , stirred for 5 min; finally, 50 g of ZnO was added, and after stirring for 1.5 h, a negative electrode active material composition slurry was obtained.

...

Embodiment 2

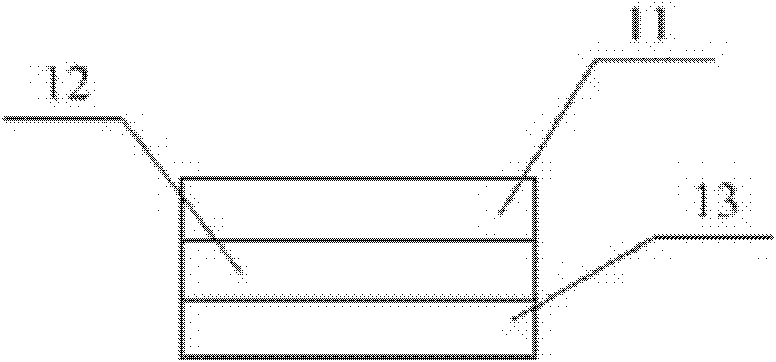

[0145] Example 2 Preparation of Negative Electrode Matrix

[0146] The first 0# zinc foil strip with a thickness of 0.05mm, the T2 pure copper foil strip with a thickness of 0.05mm and the second 0# zinc foil strip with a thickness of 0.05mm were subjected to oil storage, rust removal and drying treatment Finally, compound in a closed metal compound machine filled with nitrogen, and the compound temperature is 407°C to obtain a compound metal strip with the structure of the first zinc foil / copper foil / second zinc foil;

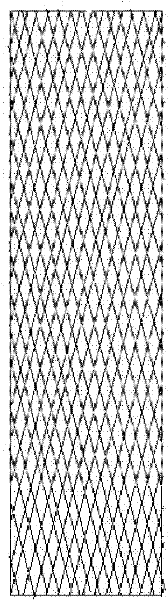

[0147] The composite metal strip is stamped and cut into a cable-stayed mesh metal strip through metal cutting and pulling equipment, and the surface density of the cable-stayed mesh metal strip is 300g / m 2 ;

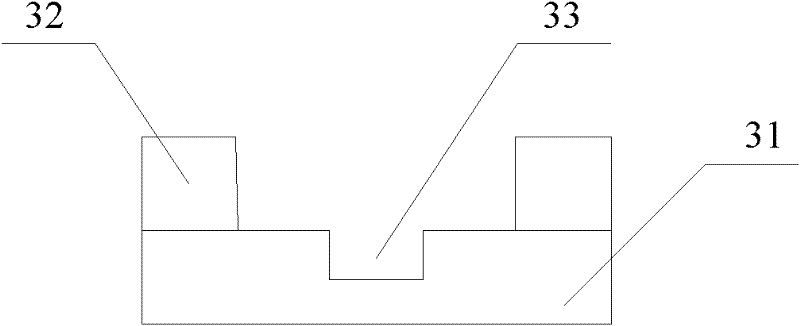

[0148] The sides of the cable-stayed mesh metal strip with a width of 3mm on both sides are symmetrically bent, folded and flattened to obtain a cable-stayed mesh metal strip with protrusions; a strip with a width of 3mm, After a groove with a depth o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com