Phase change microcapsules and preparation method thereof

A phase-change microcapsule and capsule wall technology, which is applied in microcapsule preparations, microsphere preparation, chemical instruments and methods, etc., can solve the problems of low adjustability of paraffin phase change temperature, restricting the application of phase change microcapsules, etc. Good thermal and solvent stability, easy operation, high enthalpy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The present invention also provides a preparation method of phase change microcapsules, comprising the following steps:

[0032] dissolving chitosan in an aqueous acetic acid solution to obtain an aqueous chitosan solution;

[0033] Add molten fatty alcohol to the chitosan aqueous solution, and obtain primary emulsion after emulsification;

[0034] adding the primary emulsion into liquid paraffin, and stirring to obtain a double emulsion;

[0035] Glutaraldehyde is added into the double emulsion to obtain phase change microcapsules after reaction.

[0036] Firstly, chitosan is dissolved in acetic acid aqueous solution to obtain chitosan aqueous solution. In the present invention, the chitosan is preferably a chitosan with a deacetylation degree of 70% to 95%, more preferably a chitosan with a deacetylation degree of 75% to 90%. The mass concentration of the aqueous acetic acid solution is preferably 0.05%-2%, more preferably 0.1%-1.5%, most preferably 0.3%-0.6%. The...

Embodiment 1

[0050] 3g of chitosan with deacetylation degree of 85% is dissolved in 200mL mass concentration of 0.5% acetic acid aqueous solution to obtain chitosan aqueous solution; the chitosan aqueous solution is heated to 55°C, and 6g of melting point is added dropwise thereto. Melted n-hexadecanol at 52°C was stirred at a speed of 1000 rpm for 2 hours to obtain a white viscous primary emulsion;

[0051] Add 50 mL of primary emulsion dropwise to 200 mL of liquid paraffin and stir for 1 h to obtain a double emulsion; add 5 g of glutaraldehyde aqueous solution with a mass concentration of 25% to the double emulsion for cross-linking reaction, suction filter the obtained reaction product, dilute NaOH After solution washing, water washing and drying, dark yellow phase-change microcapsules are obtained.

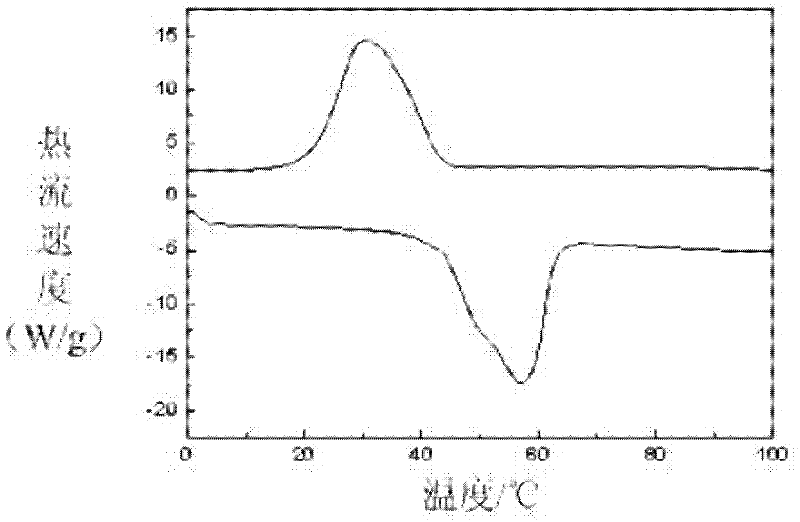

[0052] The phase-change microcapsules were observed with an optical microscope, and the results can be found in figure 1 , figure 1 The photomicrograph of the phase change microcapsule p...

Embodiment 2

[0058] The phase-change microcapsules were prepared according to the raw materials, steps and methods provided in Example 1, with the difference that when preparing the primary emulsion, the stirring speed was 400 rpm.

[0059] The DSC scanning of the phase change microcapsules showed that the crystallization enthalpy was 120 J / g, and the melting enthalpy was 130 J / g.

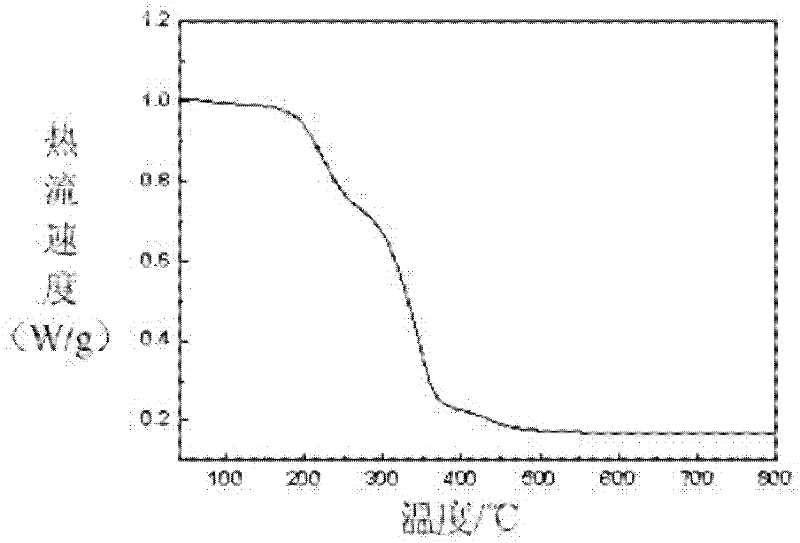

[0060] The TGA analysis of the phase change microcapsules shows that it has good thermal stability and can be used below 200°C.

[0061] The phase-change microcapsules were added to ethanol, chloroform, tetrahydrofuran, acetone, dimethyl sulfoxide, N,N-dimethylformamide and ether, and the results showed that they had good solvent resistance and were insoluble in Common solvents such as ethanol, chloroform, tetrahydrofuran, acetone, dimethyl sulfoxide, N,N-dimethylformamide and ether.

[0062] The phase-change microcapsules were added to an aqueous solution of acetic acid with a mass concentration of 1.5%, soak...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com