A method of preparation of natural bone repair materials

A technology for repairing materials and natural bone, applied in medical science, prosthesis, etc., can solve the problems of allograft bone graft rejection, few sources of autologous bone graft, poor osteogenesis ability, etc., and achieve good tissue compatibility, good mechanical The effect of improving the scientific characteristics and promoting the speed of repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

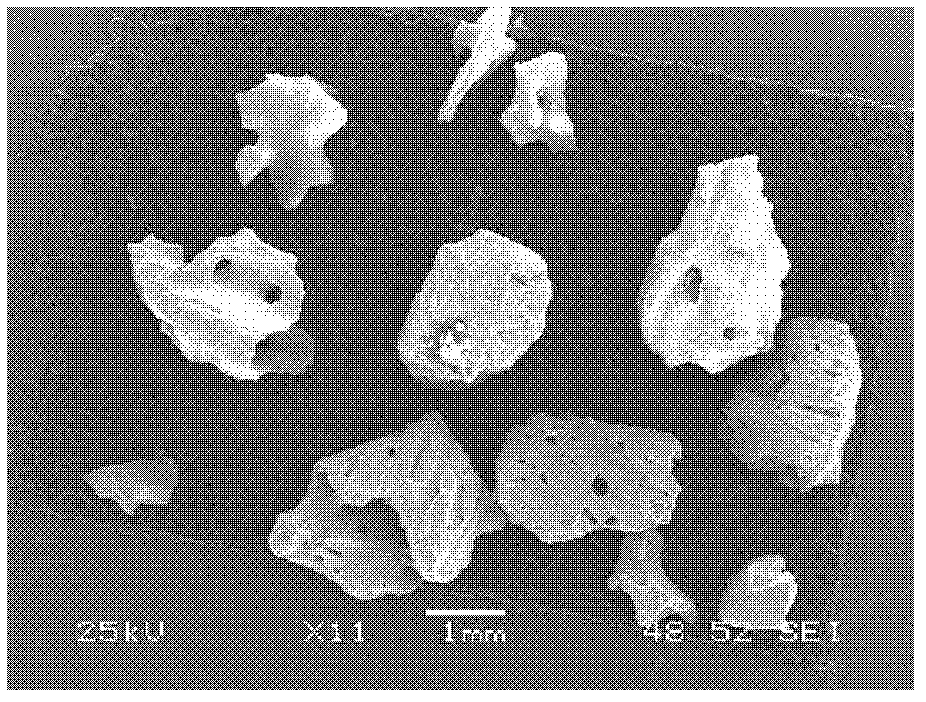

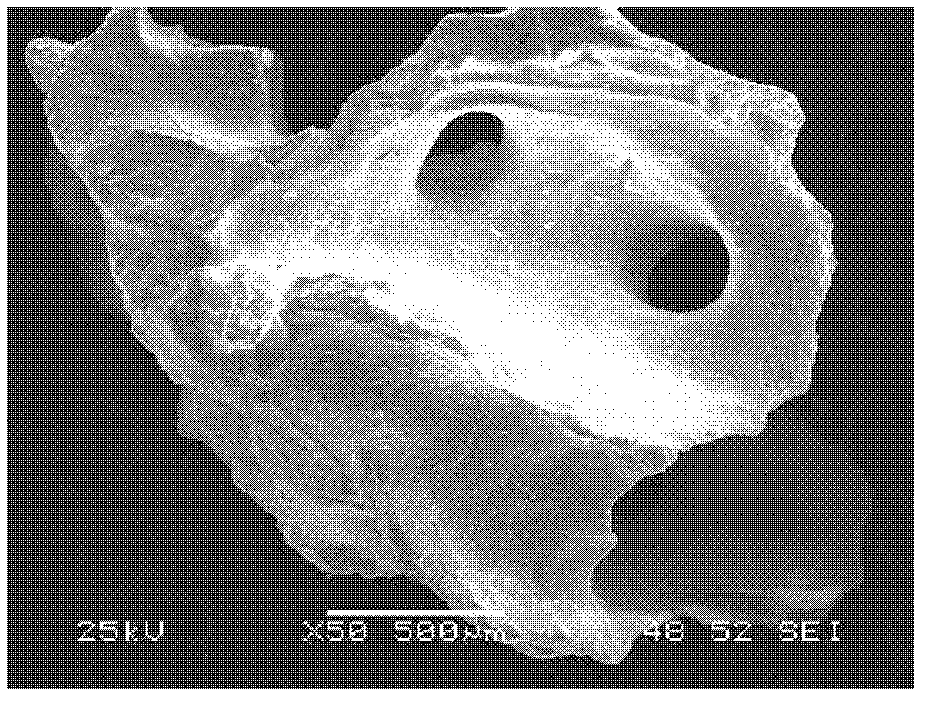

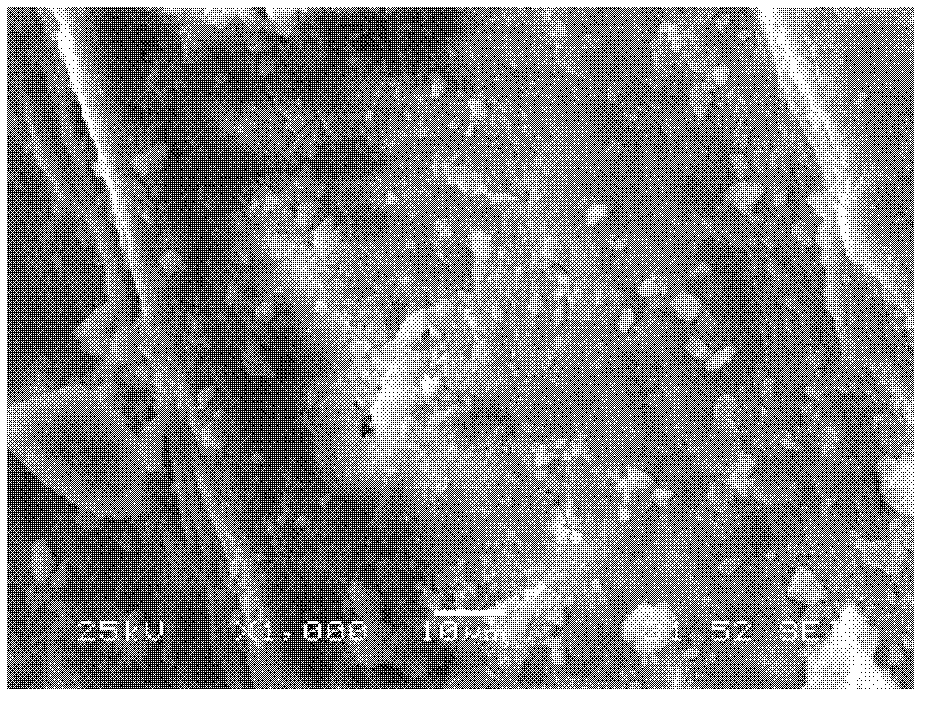

[0009] Specific embodiment one: the preparation method of a kind of natural bone repair material of this embodiment, carries out according to the following steps: one, remove the soft tissue and bone marrow attached on cancellous bone, then cut into blocks, then put in mass percent concentration and be 1.4 % ~ 1.6% glutaraldehyde sodium phosphate buffer solution for 3 ~ 5h, rinse with distilled water for 3 ~ 5 times, soak in 0.5 ~ 2mol / L NaOH solution for 3 ~ 5h, and then use 0.05 ~ 0.2mol / L of sodium phosphate buffer and washed 3 to 5 times, and the cancellous bone after washing with sodium phosphate buffer was placed in an aspartic acid solution with a pH value of 7.2 to 7.6 and a mass percent concentration of 0.4% to 0.6%. 1 to 2 hours, and then sterilized with cobalt 60 with a radiation dose of 25kGy for 1 to 3 hours to obtain the deantigenated cancellous bone; 2. Place the deantigenated cancellous bone in a heat treatment furnace and calcinate at 830 to 870°C for 1 to 3 h...

specific Embodiment approach 2

[0011] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is: in step 1, fix in 1.5% glutaraldehyde sodium phosphate buffer for 4 hours. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0012] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in Step 1, soak in 1 mol / L NaOH solution for 4 hours. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com