Method for treating organic dyestuff in wastewater

A technology for organic dyes and wastewater treatment, applied in water/sewage treatment, chemical instruments and methods, oxidized water/sewage treatment, etc., can solve the problems of low treatment efficiency, high cost, complicated preparation, etc., and achieve good degradation effect, pH The effect of stable value and complete degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

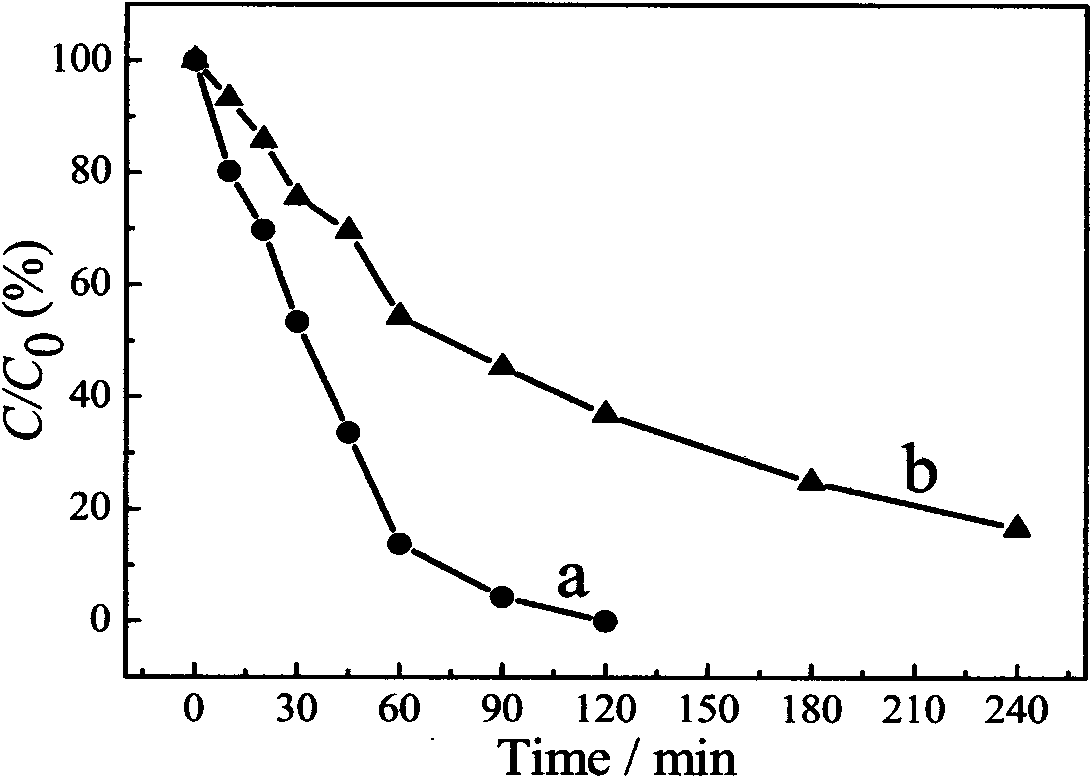

Embodiment 1

[0031] A kind of electro-Fenton's method that treats methyl orange in wastewater with nanometer zero valent iron as iron source, comprises the following steps:

[0032] S1: Preparation of nano-sized zero-valent iron

[0033] Prepare 0.27mol·L-1 FeSO 4 ·7H 2 O solution and an equal volume of 0.54molL-1 NaBH 4 solution. FeSO 4 ·7H 2 O solution is moved into the reactor, and then use a constant flow pump to add NaBH at a constant speed of 40-60rpm (preferably 50rpm) 4 solution. During the reaction process, a mechanical stirrer was used to stir, and high-purity nitrogen was continuously fed into the reactor for protection. NaBH 4 After the solution is completely added, let it stand and age for 15-25min (preferably 20min) until no bubbles are generated in the solution. At this time, the FeSO in the solution 4 was fully restored. Suction filter the prepared iron powder, wash with distilled water and absolute ethanol successively until the iron powder is loose without obvio...

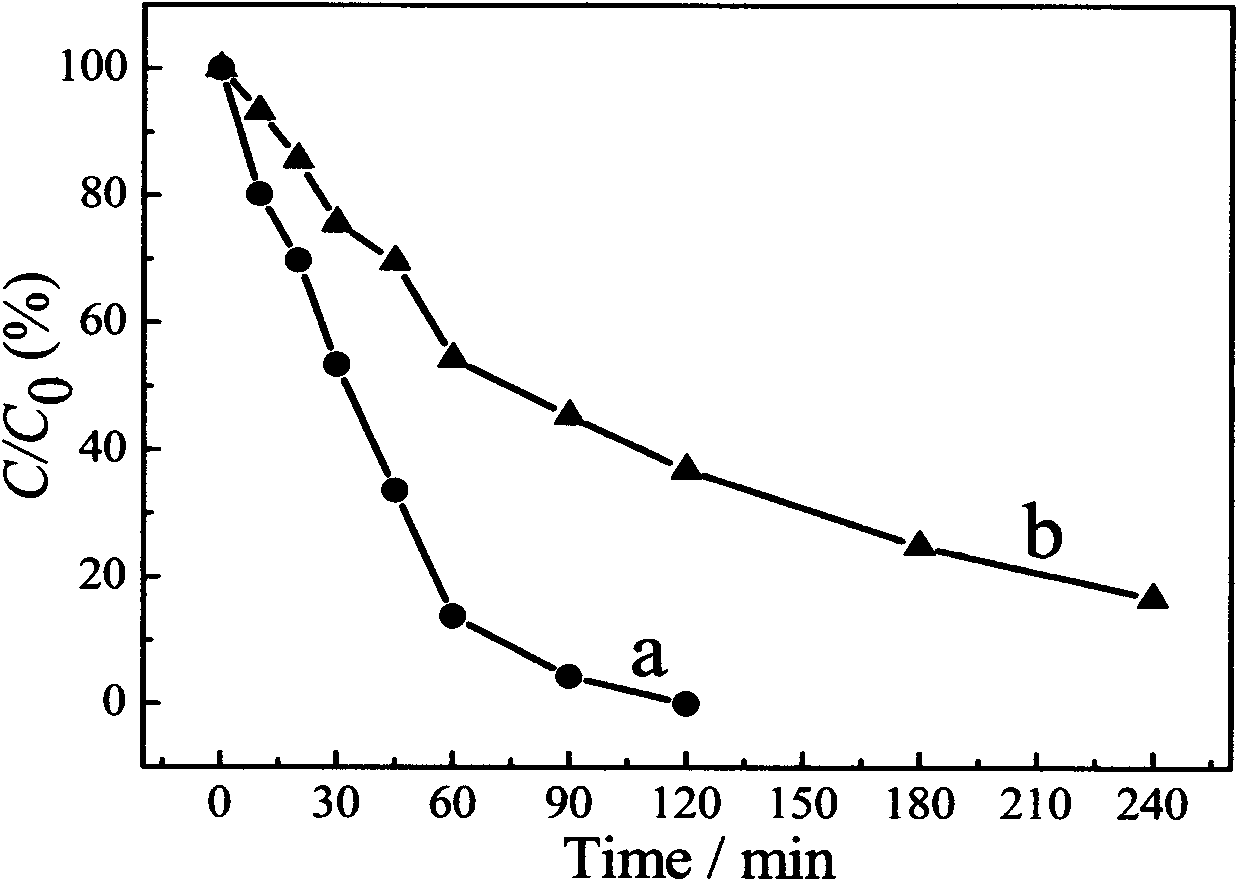

Embodiment 2

[0038] A kind of electro-Fenton method processing dimethyl phthalate in waste water with nanometer zero valent iron as iron source, comprises the following steps:

[0039] S1: Preparation of nano-sized zero-valent iron

[0040] Prepare 0.27mol·L-1 FeSO 4 ·7H 2 O solution and an equal volume of 0.54molL-1 NaBH 4 solution. FeSO 4 ·7H 2 O solution was moved into the reactor, and NaBH was added at a constant speed of 50rpm using a constant flow pump. 4 solution. During the reaction process, a mechanical stirrer was used to stir, and high-purity nitrogen was continuously fed into the reactor for protection. NaBH 4 After the solution is completely added, let it stand and age for about 20 minutes until no bubbles are generated in the solution. At this time, the FeSO in the solution 4 was fully restored. Suction filter the prepared iron powder, wash with distilled water and absolute ethanol successively until the iron powder is loose without obvious moisture. During suction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com