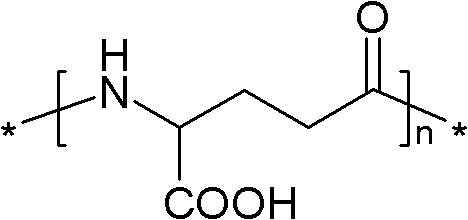

Drought-resisting and water-holding seed coating formulation containing gamma-polyglutamic acid and preparation method thereof

A technology of polyglutamic acid and insecticide, which is applied in the field of seed treatment, can solve the problems of low seed germination rate, abnormal germination, and waste of water resources in arid areas, so as to ensure the rooting and germination of crops, increase the effective water content, The effect of preventing pests and diseases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

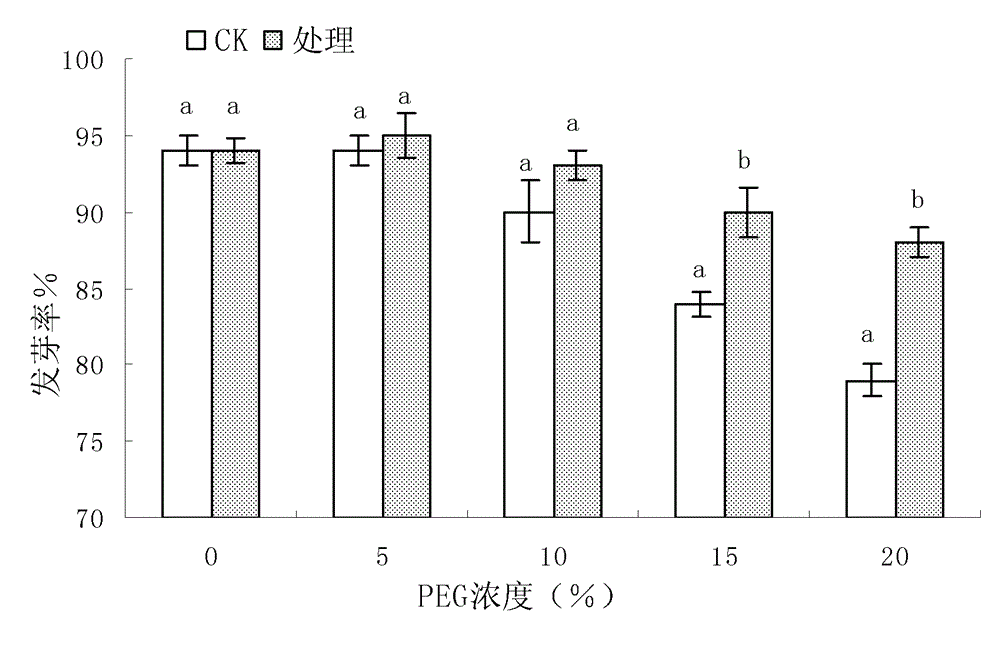

[0042]Example 1: Drought Resistant Maize Seed Coating.

[0043] The drought-resistant corn seed coating is composed of the following raw materials in mass percentage:

[0044] γ-polyglutamic acid 0.2%, polyacrylamide 2%, polyethylene glycol octylphenyl ether 1%, manganese sulfate 0.5%, zinc sulfate 0.1%, calcium carbonate 0.1%, copper sulfate 0.01%, triadimefon 1%, carbendazim 3%, carbofuran 2%, red pigment 0.5%, and the rest is water.

[0045] Add the above seed coating raw materials into a mixer and mix well to prepare the corn seed coating agent. When coating the seeds, 20 parts by mass of corn seeds and 1 part by mass of the seed coating agent were prepared into coated corn seeds in a granulator.

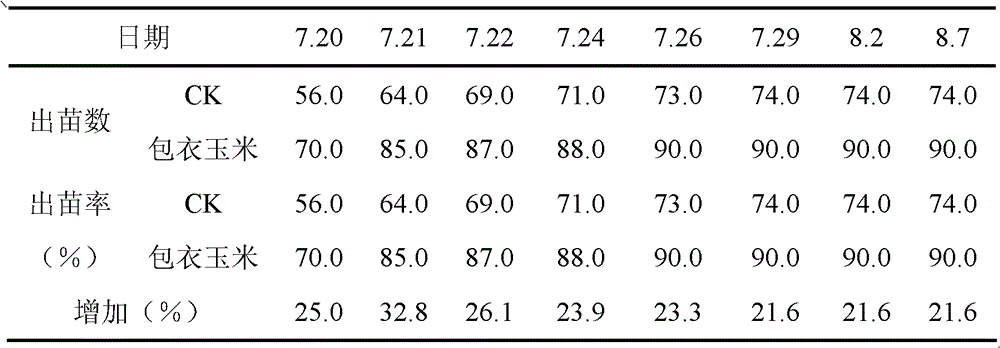

[0046] The prepared gamma-polyglutamic acid coated seeds were carried out in a field test in July-August 2010, and the uncoated corn seeds (CK) were used as a control test. 100 seeds were sown each, and the number of seedlings and the rate of emergence were listed below Table...

Embodiment 2

[0050] Example 2: Drought Resistant Cotton Seed Coating.

[0051] The drought-resistant cotton seed coating is composed of the following raw materials in mass percentage:

[0052] Gamma-polyglutamic acid sodium salt 0.8%, polyacrylamide 2%, polyoxyethylene alkyl ether 2%, manganese sulfate 0.1%, zinc sulfate 0.1%, ferrous sulfate 0.1%, triadimefon 2%, enemy grams Pine 3%, carbofuran 3%, red pigment 0.6%, and the rest is water.

[0053] Add the above seed coating raw materials into a mixer and mix well to make a cotton seed coating agent. The cotton seed of 25 mass parts and the seed coating agent of 1 mass part are made cotton coated seed in pelletizer.

[0054] The prepared gamma-polyglutamic acid coated seeds were carried out in a field test in April-May, 2010, and a control test was done with uncoated cotton seeds (CK). Table 2.

[0055] Table 2 Effect of γ-PGA seed coating agent on cotton seedling emergence rate

[0056]

[0057] As can be seen from the data in Tab...

Embodiment 3

[0058] Example 3: Drought-resistant rapeseed coating.

[0059] The drought-resistant rapeseed coating is composed of the following raw materials in mass percentage:

[0060] γ-polyglutamic acid wettable powder 2% (which contains 20% (w / w) γ-polyglutamic acid), gum arabic 5%, polyethylene glycol octyl phenyl ether 0.6%, manganese sulfate 0.05 %, zinc sulfate 0.15%, molybdenum sulfate 0.1%, copper sulfate 0.01%, chlorothalonil 3%, imidacloprid 0.5%, red pigment 0.9%, and the rest is water.

[0061] Add the above seed coating raw materials into a mixer and mix thoroughly to prepare a rapeseed coating agent. 30 parts by mass of rapeseed and 1 part by mass of the seed coating agent are used in a coating machine to make coated rapeseed seeds.

[0062] The experiment was carried out in Datang Village, Kunshan City in October 2010. Taking common rapeseed (CK) as a control, it was sown on October 15, 2010, transplanted on November 15, 2010, and the seedling quality was investigated ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com