Photopolymerizable chitosan derivative as well as preparation method and application thereof

A chitosan derivative, photopolymerization technology, applied in the field of biopolymer materials, can solve the problems of difficult control of reaction conditions, complicated post-processing, long gel time, etc., and achieves environmental protection, good biocompatibility, simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Add chitosan (deacetylation degree DD=70%, weight average molecular weight Mw=50,000) into 2wt% acetic acid solution, stir at room temperature for 0.5h, and prepare 1% by weight chitosan solution. Adding methacryloylglycine, EDC and NHS added to 15mL deionized water with an amount of 2 times the amino molar number on the chitosan, the mol ratio of methacryloylglycine, EDC, NHS is 1: 2: 2, The carboxyl group was activated by magnetic stirring for 2 h. It was slowly added dropwise to the acetic acid solution of chitosan, and reacted at room temperature for 6h. Adjust the pH value to 8 with 1mol / L NaOH solution, dialyze with deionized water, and freeze-dry to obtain photopolymerizable chitosan derivatives. The product structure is as follows:

[0039]

[0040] Wherein, n=0.7, m=0.3, 0

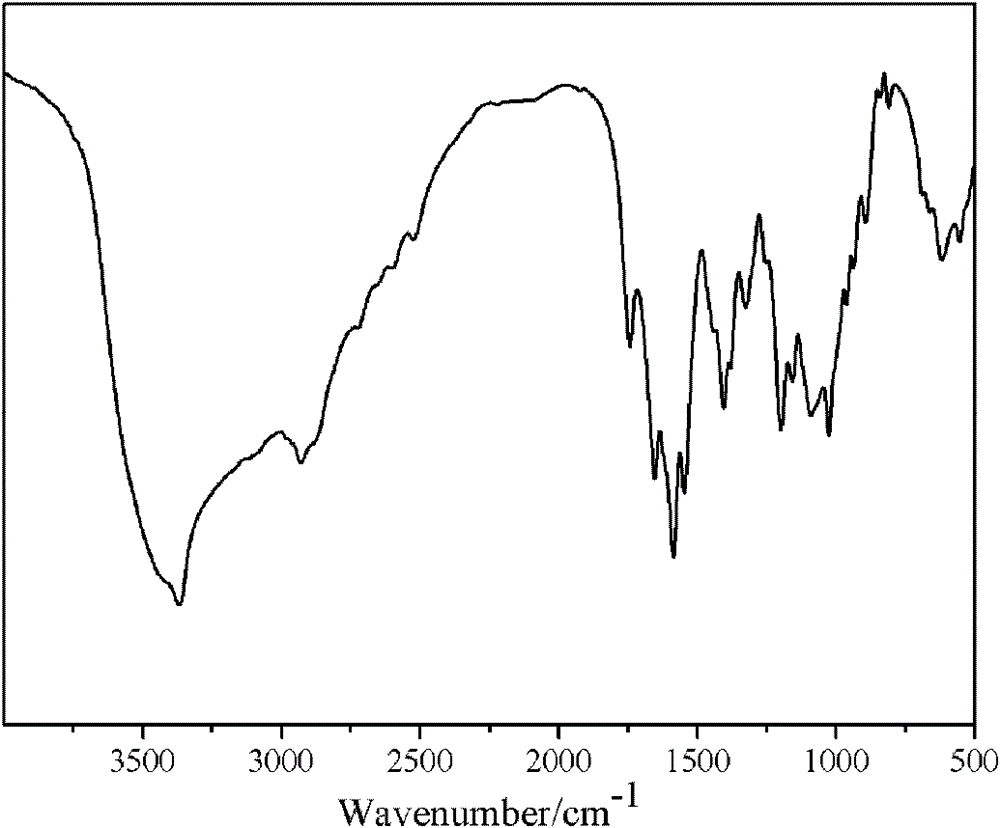

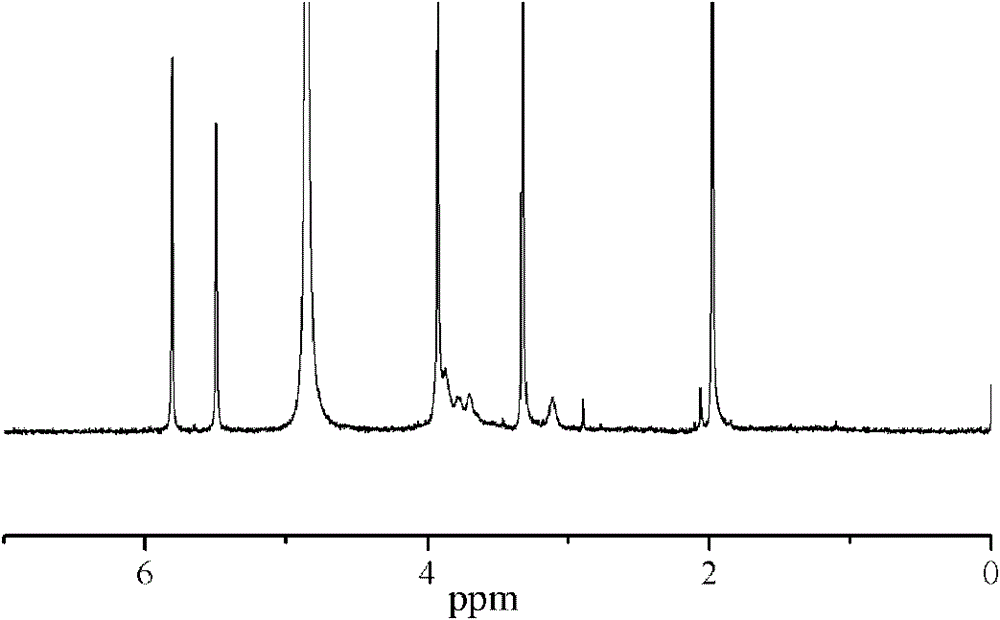

[0041] Figure 1A with 1B The IR spectrum and H NMR spectrum of the product methacryloylglycyl chitosan are given respectively.

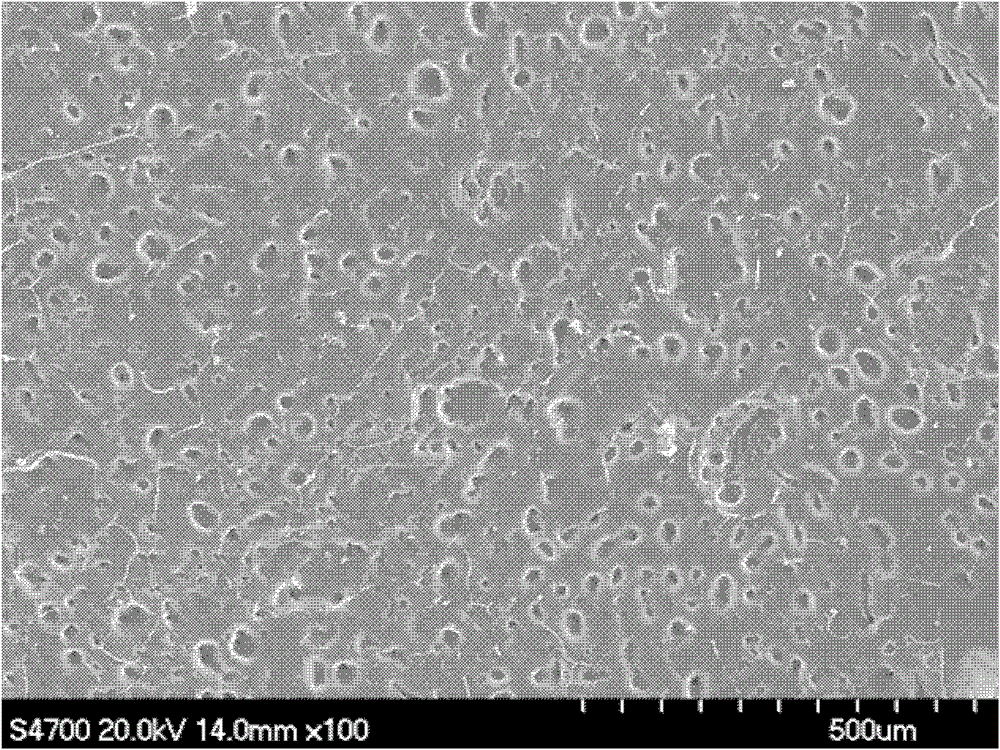

[0042] The prepared photopolymerizable chito...

Embodiment 2

[0044] Add chitosan (deacetylation degree DD=90%, weight average molecular weight Mw=100,000) into 2wt% acetic acid solution, stir at room temperature for 1 hour, and prepare chitosan solution with a weight percentage of 1%. Adding methacryloylglycine, EDC and NHS added to 15mL deionized water with an amount of 2 times the molar amino group on the chitosan, the mol ratio of methacryloylglycine, EDC, NHS is 1: 4: 4, The carboxyl group was activated by magnetic stirring for 2 h. It was slowly added dropwise to the acetic acid solution of chitosan, and reacted at room temperature for 8h. Adjust the pH value to 8 with 1mol / L NaOH solution, dialyze with deionized water, and freeze-dry to obtain photopolymerizable chitosan derivatives. The product structure is as follows:

[0045]

[0046] Wherein, n=0.9, m=0.1, 0

[0047] The prepared photopolymerizable chitosan derivative is dissolved in 2wt% acetic acid solution to form a solution of 85% by weight, adding 1% of photopo...

Embodiment 3

[0049] Add chitosan (deacetylation degree DD=80%, weight average molecular weight Mw=50,000) into 2wt% acetic acid solution, stir at room temperature for 2h, and prepare 2wt% chitosan solution. Adding methacryloylglycine, EDC and NHS added to 15 mL of deionized water with an amount of 1 times the molar amino group on chitosan, the mol ratio of methacryloylglycine, EDC, NHS is 3: 2: 2, The carboxyl group was activated by magnetic stirring for 3 h. It was slowly added dropwise to the acetic acid solution of chitosan, and reacted at room temperature for 8h. Adjust the pH value to 8 with 1mol / L NaOH solution, dialyze with deionized water, and freeze-dry to obtain photopolymerizable chitosan derivatives. The product structure is as follows:

[0050]

[0051] Wherein, n=0.8, m=0.2, 0

[0052] The prepared photopolymerizable chitosan derivative is dissolved in 2wt% acetic acid solution to form a solution of 80% by weight, and 2% of the photopolymerizable chitosan derivat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com