Enzymatic extraction of rice distiller's grain protein production process

A production process and enzymatic extraction technology, applied in the field of protein extraction process, can solve the problems of reducing extraction efficiency, reducing protein nutritional value, protein denaturation, etc., and achieve the effect of improving extraction efficiency, high extraction efficiency and less side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Preferred embodiment one of the present invention comprises the following steps:

[0016] 1. The rice distiller's grains are washed with water to remove impurities, and then hydrolyzed with cellulase. After the cellulase hydrolysis treatment, the rice wine grains are dried to make the water content 50%.

[0017] 2. Alkaline enzyme and a-amylase at a ratio of 5:1 were used as enzyme preparations, the amount of enzyme added was 1832 AU, and the protein hydrolysis of rice wine lees was carried out at a temperature of 49°C and a pH value of 9.5 for 4 hours.

[0018] 3. Using membrane separation technology to separate the protein hydrolyzate of rice distiller's grains, the pressure is 30psi, the pH value is 9, the concentration ratio is 5:1, the temperature is room temperature, and the permeation flux is 33.2L / m 2 h.

Embodiment 2

[0019] The second preferred embodiment of the present invention comprises the following steps:

[0020] 1. The rice distiller's grains are washed with water to remove impurities, and then hydrolyzed with cellulase. After the cellulase hydrolysis treatment, the rice wine grains are dried to make the water content 48%.

[0021] 2. Alkaline enzyme and a-amylase at a ratio of 5:1 were used as enzyme preparations, the amount of enzyme added was 1832 AU, and the protein hydrolysis of rice wine grains was carried out at a temperature of 48°C and a pH value of 9.5 for 4 hours.

[0022] 3. Using membrane separation technology to separate the protein hydrolyzate of rice distiller's grains, the pressure is 30psi, the pH value is 9, the concentration ratio is 5:1, the temperature is room temperature, and the permeation flux is 33.2L / m 2 h.

Embodiment 3

[0023] The third preferred embodiment of the present invention comprises the following steps:

[0024] 1. The rice wine grains are washed with water to remove impurities, and then hydrolyzed with cellulase. After the cellulase hydrolysis treatment, the rice wine grains are dried to make the water content 52%.

[0025] 2. Alkaline enzyme and a-amylase at a ratio of 5:1 were used as enzyme preparations, the amount of enzyme added was 1832 AU, and the protein hydrolysis of yellow distiller's grains was carried out at a temperature of 50°C and a pH value of 9.5 for 4 hours.

[0026] 3. Using membrane separation technology to separate the protein hydrolyzate of rice distiller's grains, the pressure is 30psi, the pH value is 9, the concentration ratio is 5:1, the temperature is room temperature, and the permeation flux is 33.2L / m 2 h.

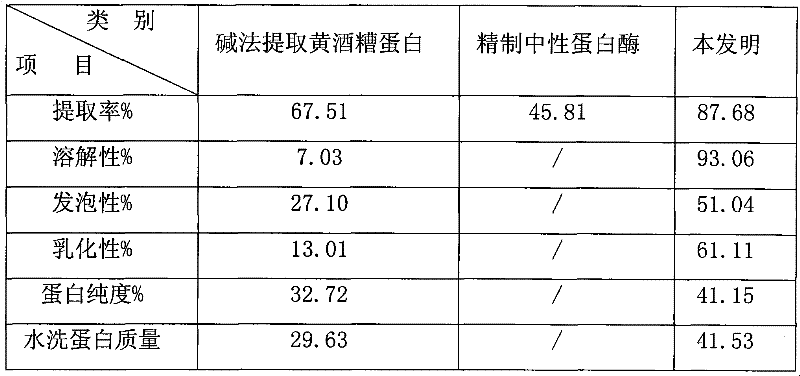

[0027] Adopt the main index of the product that the present invention obtains with other methods at home and abroad to compare as follows:

[0028...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com