A heat treatment process for low carbon alloy materials

A low-carbon alloy and process technology, applied in the direction of metal material coating process, coating, solid-state diffusion coating, etc., can solve the problems of unsatisfactory requirements, unsatisfactory system heat treatment technology, etc., and achieve service life extension, bending Improvement of performance, effect of increasing hardness and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Prepare the material and take the rivet made of 12CR2NI4 alloy material to remove the surface debris.

[0032] Thermal treatment, the rivet made of the above 12CR2NI4 alloy material is treated according to the following steps,

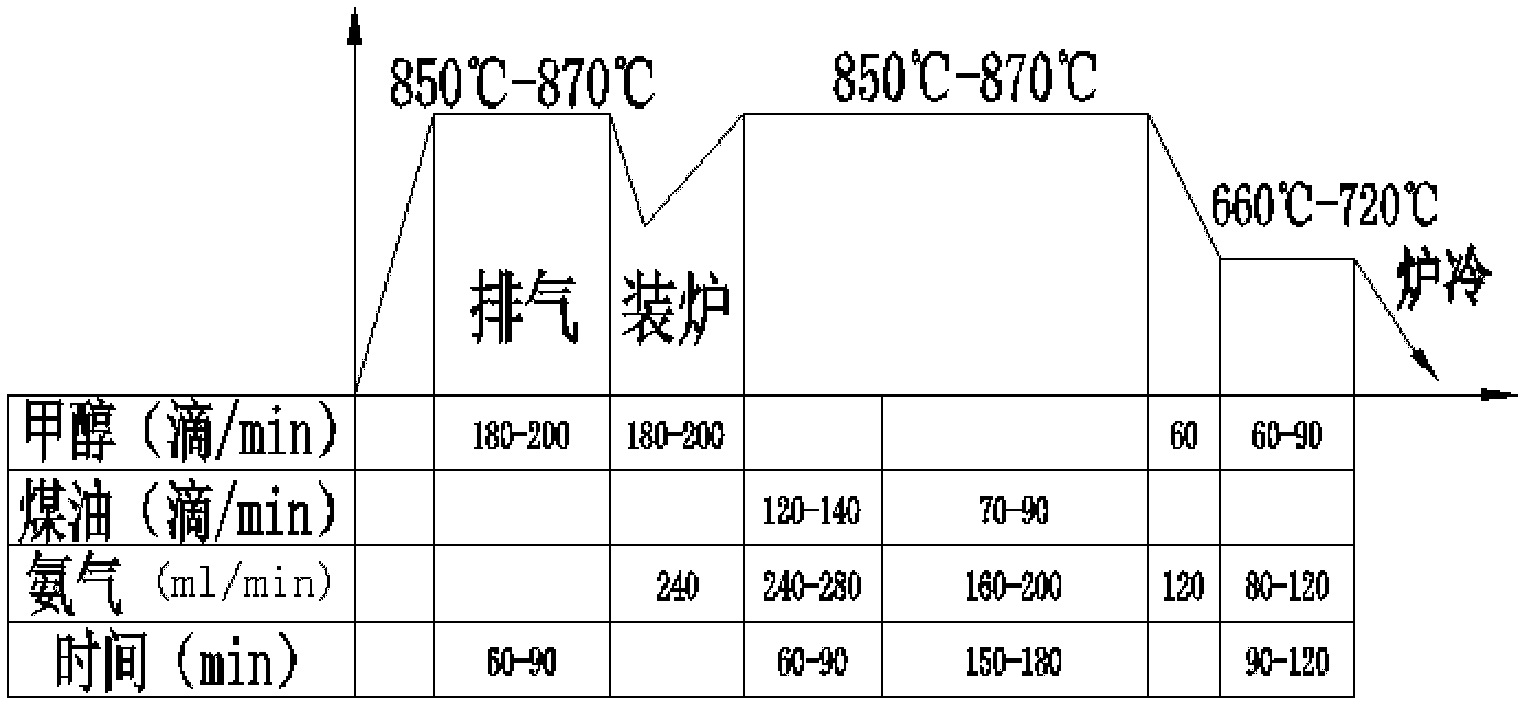

[0033] 1. Carbon and nitrogen penetrate together. Under the conditions of 850 ° C to 870 ° C, the processing workpiece is dripped at 180 to 200 drops per minute and the water -free methanol is dropped. After the stability lasts for 60 to 90 minutes, it will be 120 to 140 drops per minute per minute.The speed dripping coal oil is at the same time of 240 to 280 ml / minute.After 99.99 % ammonia qi 150 to 180 minutes; the cooling to 660 ° C to 720 ° C, dripping at a speed of 60 to 90 drops per minute, plus water -free methanol at the same time at 80-120 ml / minute, 99.99 % ammonia gas 90 ~From 120 minutes to normal temperature; the following table can be used in the field of carbon and nitrogen.

[0034] 2. After quenching, the carbon nitrogen seeps is se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com