trimethyl chitosan fiber

A technology for trimethyl chitosan and fiber, applied in the field of trimethyl chitosan fiber, can solve the problems of inconvenient preparation process and low acetylation degree, and achieve the effects of easy preparation and good water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A trimethyl chitosan fiber contains the following components: 5 g of trimethyl chitosan, 1.0 g of urea, 1.0 g of isopropanol, 5 g of dichloroacetic acid, 1.0 g of glycerin, 5 g of zinc acetate, and 84 g of water.

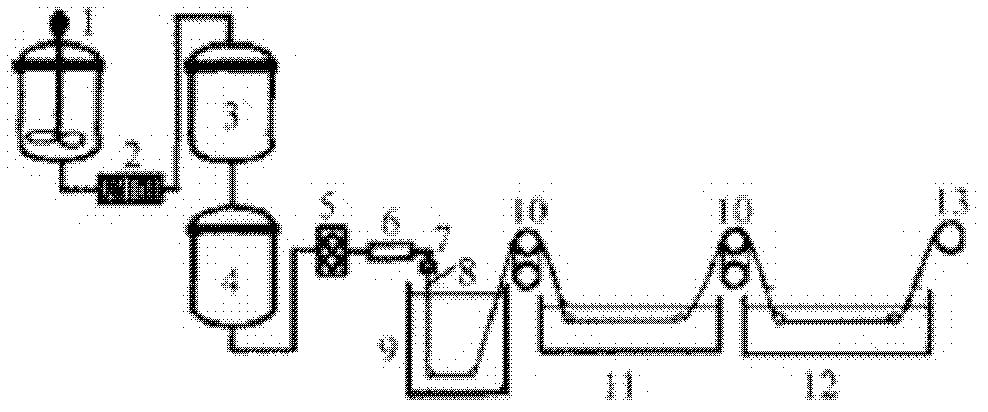

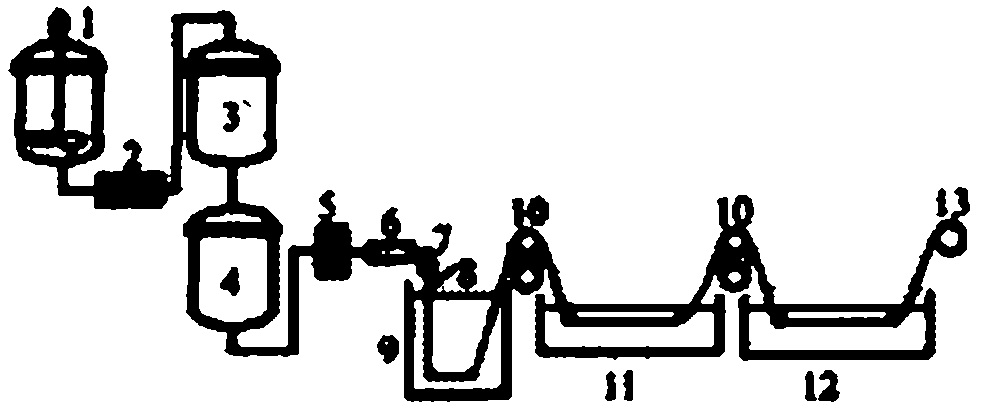

[0019] refer to figure 1 As shown, weigh trimethyl chitosan and other components into the distilled water in the dissolution kettle 1 and stir to make it fully dissolved into a clear and transparent light yellow spinning stock solution. Under pressure, the stock solution passes through the plate and frame filter 2 , enter the slow release barrel 4 after removing impurities, and degas the stock solution in the stock solution barrel under vacuum conditions. The stream passes through a section of air layer 8 before entering the coagulation bath 9 to generate solid as-spun fibers, then stretches through the stretching roller 10, washes in the stretching bath 11 and water bath 12, and obtains microcrystals after winding and drying by the winding roller 13. Cel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com