A kind of preparation method of water-stable γ-polyglutamic acid nanofiber

A technology of polyglutamic acid and nanofibers, applied in fiber treatment, chemical post-treatment of synthetic polymer artificial filaments, single-component polypeptide artificial filaments, etc., can solve the problem of inability to obtain water-stable γ-PGA nanofibers, There are no problems such as γ-PGA nanofiber crosslinking, adverse effects on operators and the environment, and achieve the effects of mild process conditions, good biocompatibility, and easy process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

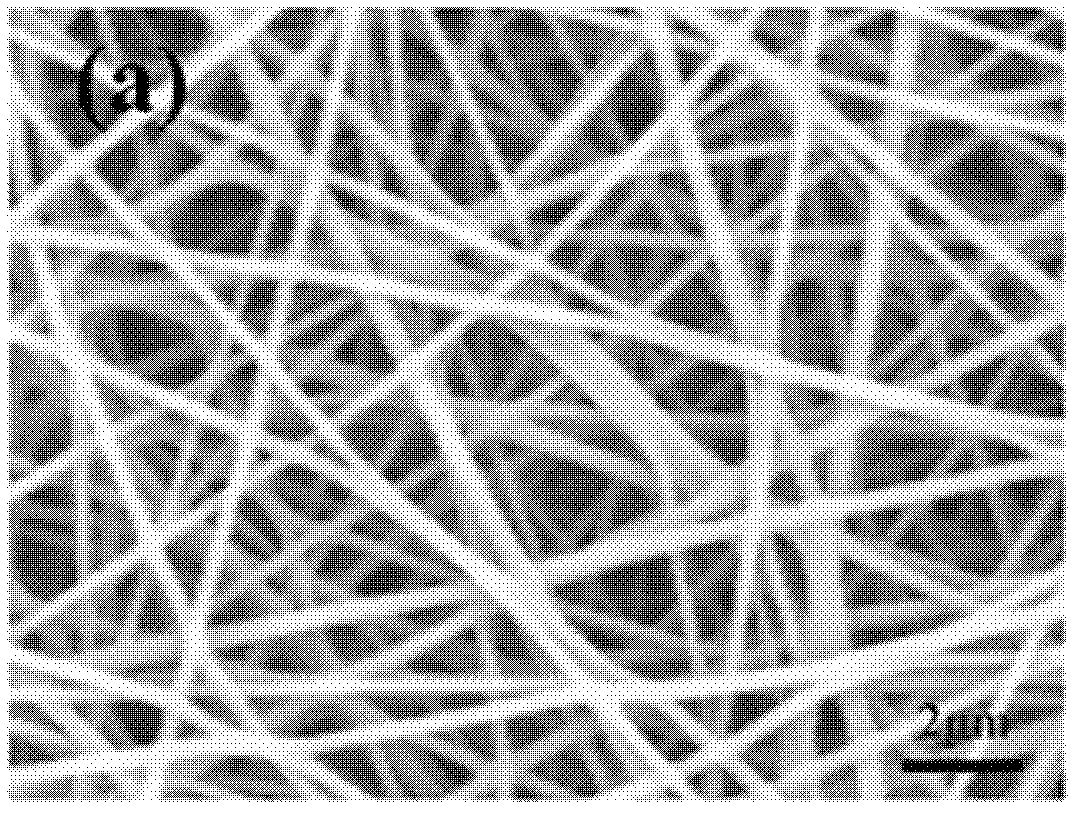

[0035] Take 0.8 grams of γ-PGA powder respectively, dissolve them in 5%, 8% and 10% TFA aqueous solution, stir magnetically for 8 hours to fully dissolve the γ-PGA powder, and prepare three kinds of γ-PGA with a mass percentage concentration of 16%. The solution was stored in a refrigerator at 4°C for later use. When spinning, inject the above three spinning liquids into the syringe pump respectively, the electrospinning process parameters are spinning voltage 32kV, receiving distance 40cm, flow rate 0.3mL / h, humidity not higher than 40%, spinning needle No. 17 Stainless steel needle (1.07mm inner diameter, 1.47mm outer diameter). The aluminum foil collected with the above three different nanofibers was dried in a vacuum desiccator for 24 hours, and then the above aluminum foil was cut to a suitable size and placed in absolute ethanol to peel the fibers from the aluminum foil. SEM observation showed (as shown in FIG. 2 ) that the fibers obtained above had regular morphology a...

Embodiment 2

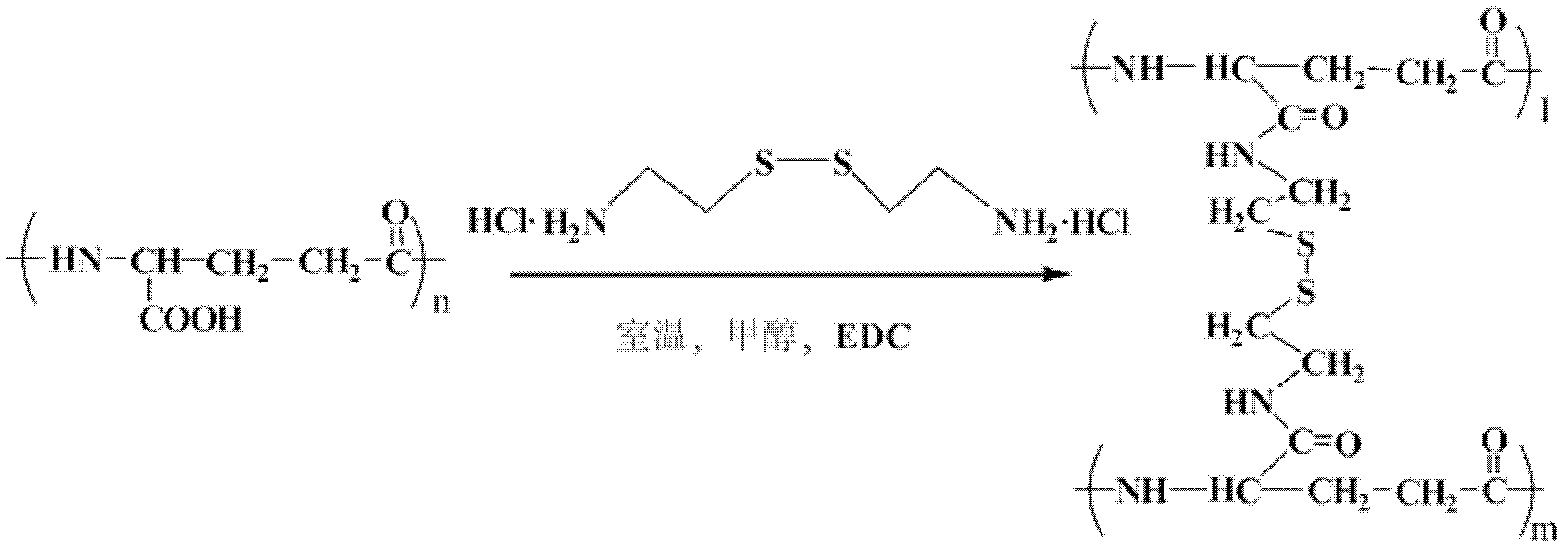

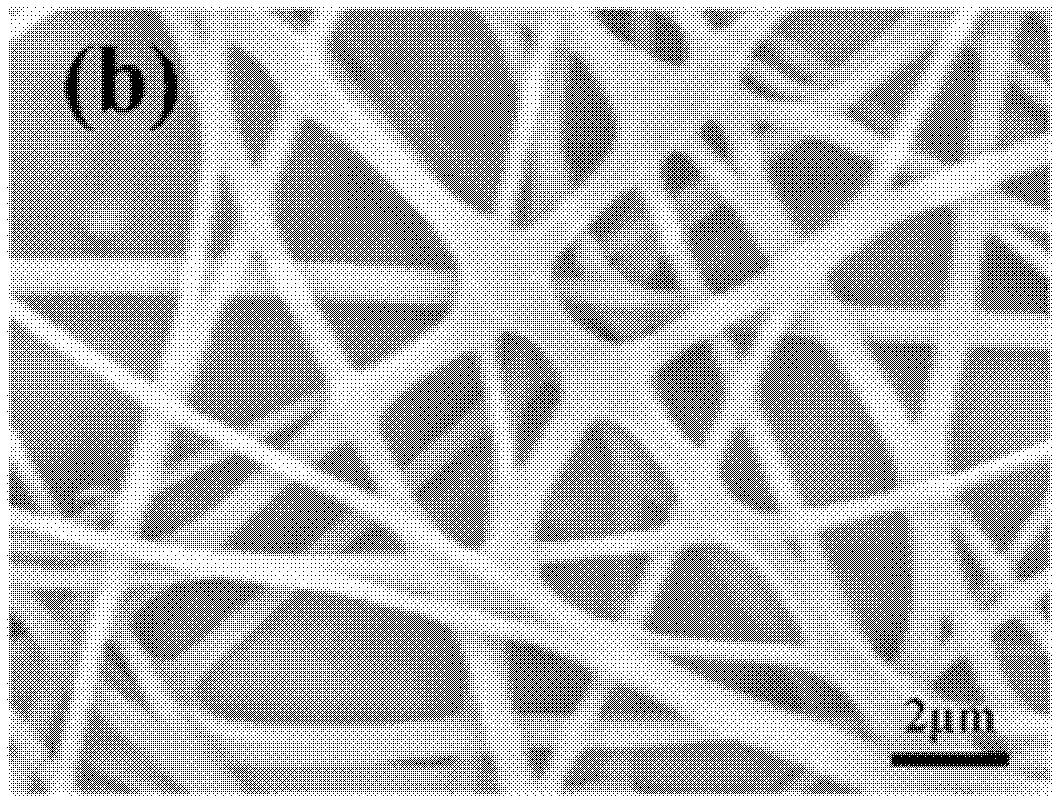

[0037]Weigh 50 mg of each of the above three different nanofibers and immerse them in 25 mL of anhydrous methanol respectively. Each weighed 750mg of EDC activator, and dissolved it in the above 25mL of anhydrous methanol to activate the carboxyl group on the γ-PGA polymer chain. The activation time was 3 hours, and the activation condition was shaking at room temperature. Then, 872 mg of cystamine dihydrochloride were added to each of them, and they were also reacted in a shaker at room temperature for 72 hours. After the reaction, the fiber was taken out and washed with deionized water for 3 times, and the washing time was 5 minutes each time. After freeze-drying, gamma-PGA nanofibers with good water stability are obtained. In order to evaluate the water solubility of γ-PGA nanofibers cross-linked with cystamine dihydrochloride, a small amount of cross-linked fibers were soaked in PBS buffer for 7 days, and the morphology of the fibers after soaking for 7 days was observed ...

Embodiment 3

[0039] γ-PGA nanofibers with a diameter of 274±51 nm were selected, cut into small pieces of 2 cm×2 cm, spread on a cover glass with a diameter of 1.8 cm and placed in a 24-well cell culture plate. The fibers spread on the cover glass were sterilized by ultraviolet light and soaked in DMEM high-sugar medium for 12h, then supplemented with 400 μL medium per well and inoculated 2×10 4 L929 cells. Different culture time was set for each culture plate (1, 3, 5 and 7 days and 1, 2, 4 and 8 hours, 8 culture plates in total). At the end of each culture period, 40 μL of MTT was added to the culture wells, and the culture was continued for 4 hours, so that the living cells could fully react with MTT to form MTT formazan crystals. Discard the medium in each well, add 400 μL DMSO, completely dissolve the MTT formazan crystals and record the OD value at 570 nm, and analyze the adhesion or proliferation of cells on the surface of γ-PGA nanofibers under different culture times. The effect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com