A kind of tio2 nanotube array photoanode and preparation method thereof

A nanotube array and photoanode technology, applied in the field of solar cells, can solve the problems of low light collection efficiency, long time consumption, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

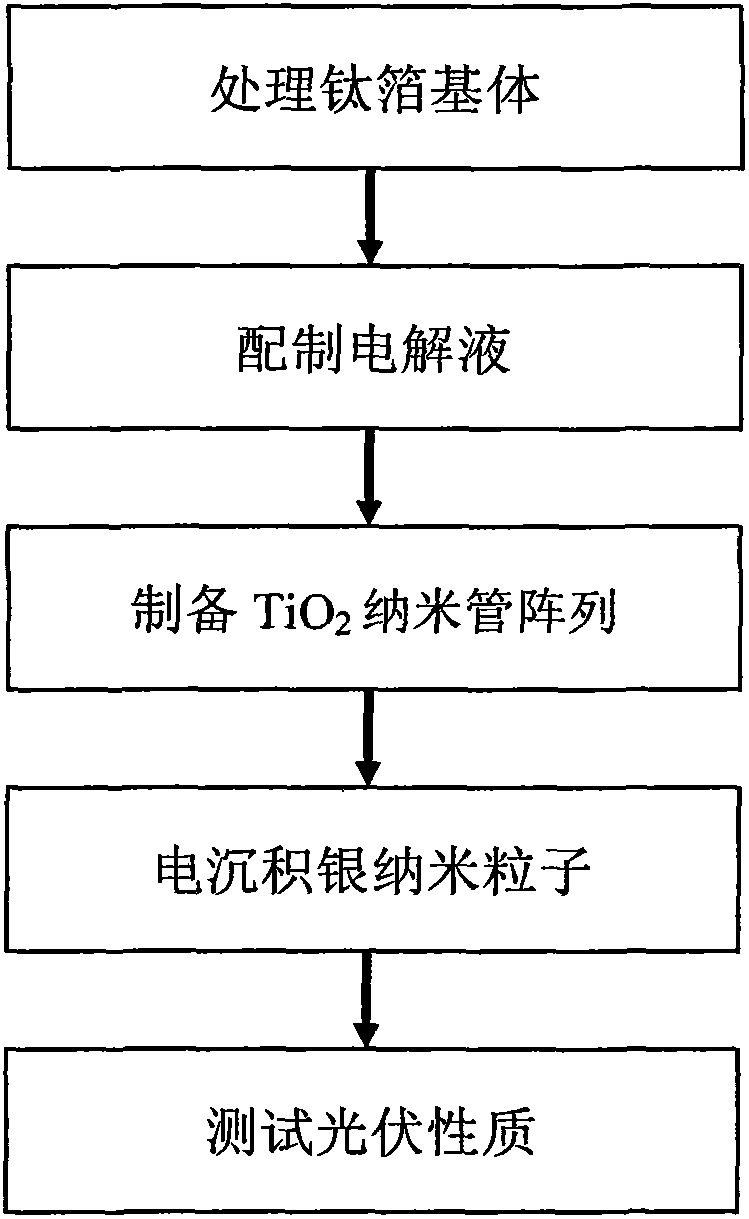

Method used

Image

Examples

Embodiment 1

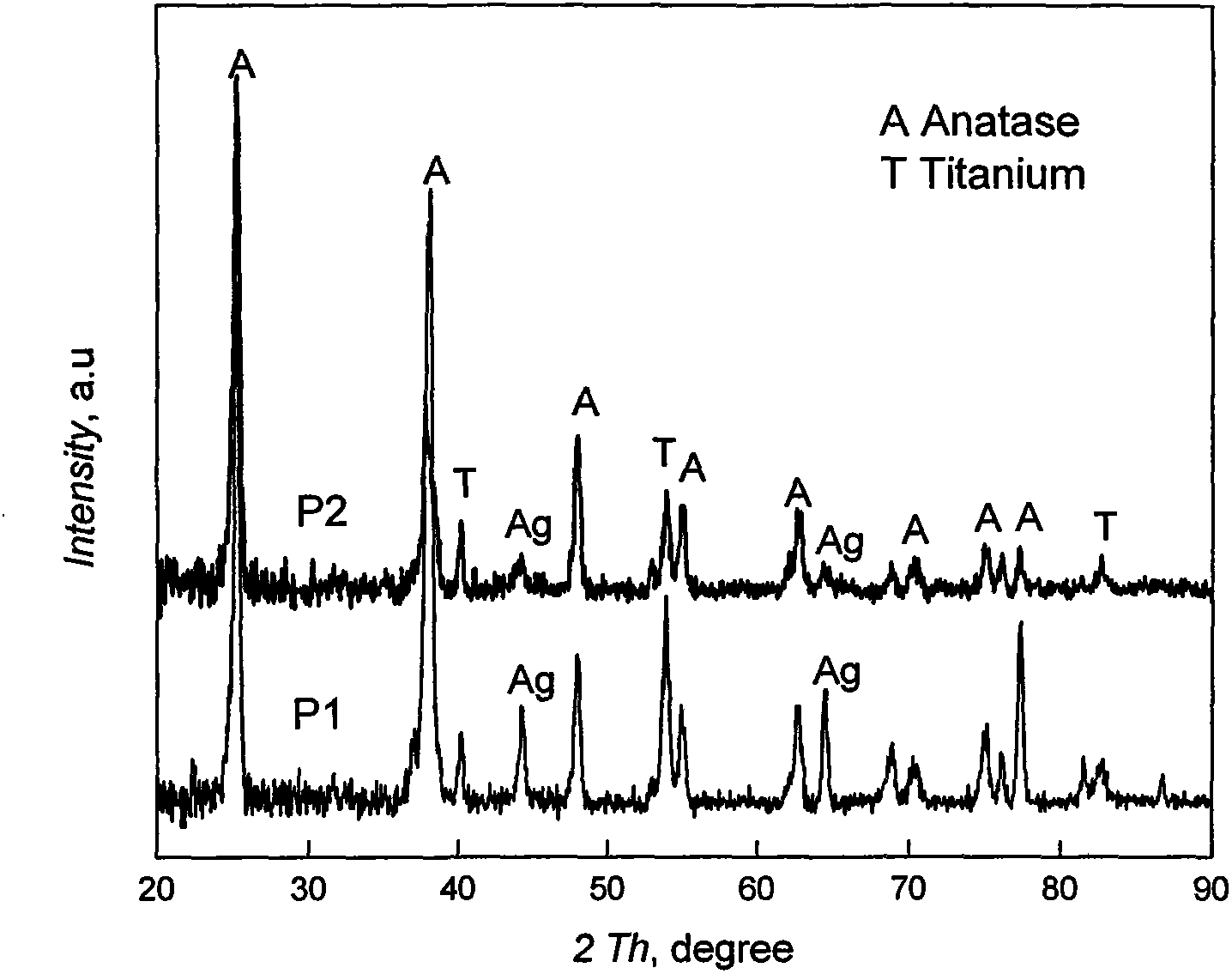

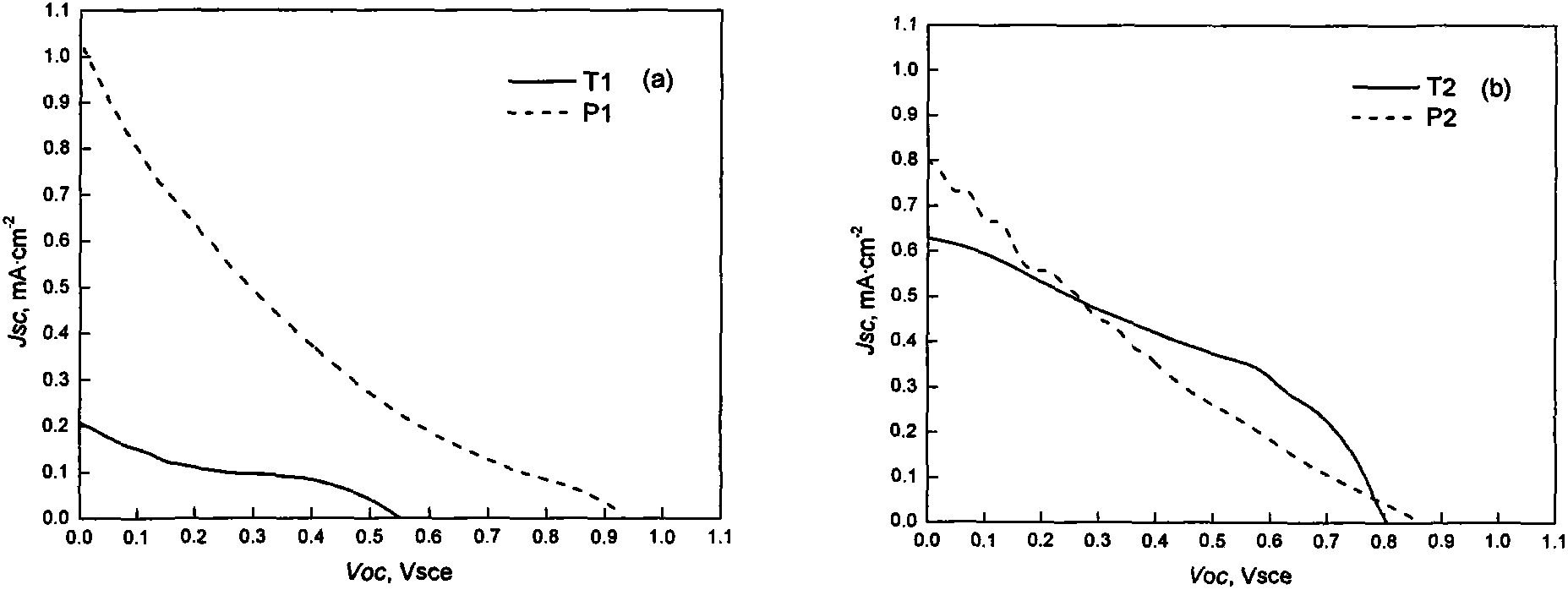

[0035] This embodiment is a TiO 2 Nanotube array photoanode, characterized in that TiO 2 The inner diameter of the nanotube is 70±4nm, the tube wall is 20±2nm, and the tube length is 1.946um. In the TiO 2 There is a silver film on the surface of the nanotube array; the microscopic surface morphology of the silver film is randomly distributed dendrites. 100-300nm.

[0036] The preparation process of this embodiment is as follows:

[0037] Step 1, processing the titanium foil substrate: cutting the titanium foil into strips of 1 cm×5 cm, polishing, and ultrasonic cleaning with acetone, absolute ethanol and deionized water for 5 minutes each; the ultrasonic power is 200 watts.

[0038] Step 2, preparing electrolyte: the electrolyte is ammonium fluoride electrolyte, silver nitrate electrolyte, saturated potassium chloride electrolyte and sodium sulfate electrolyte. in:

[0039] The ammonium fluoride electrolyte is made up of 0.25wt% ammonium fluoride, 2.5vol% deionized water...

Embodiment 2

[0046] This embodiment is a TiO 2 Nanotube array photoanode, characterized in that TiO 2 The inner diameter of the nanotube is 100±10nm, the tube wall is 20±4nm, and the tube length is 450±30nm. In the TiO 2 There is a silver film on the surface of the nanotube array; the microscopic surface morphology of the silver film is randomly distributed dendrites. 100-300nm.

[0047] The preparation process of this embodiment is as follows:

[0048] Step 1, processing the titanium foil substrate: cutting the titanium foil into strips of 1 cm×5 cm, polishing, and ultrasonic cleaning with acetone, absolute ethanol and deionized water for 5 minutes each; the ultrasonic power is 200 watts.

[0049] Step 2, prepare electrolyte: electrolyte is hydrogen fluoride electrolyte, silver nitrate electrolyte, saturated potassium chloride electrolyte and sodium sulfate electrolyte. in:

[0050] Hydrogen fluoride electrolyte is made of 0.1mol L -1 Hydrogen fluoride and 2.0mol·L -1mixed solutio...

Embodiment 3

[0057] This embodiment is a TiO 2 Nanotube array photoanode, characterized in that TiO 2 The inner diameter of the nanotube is 70±4nm, the tube wall is 20±2nm, and the tube length is 1.946um. In the TiO 2 There is a silver film on the surface of the nanotube array; the microscopic surface morphology of the silver film is randomly distributed dendrites. 100-300nm.

[0058] The preparation process of this embodiment is as follows:

[0059] Step 1, processing the titanium foil substrate: cutting the titanium foil into strips of 1 cm×5 cm, polishing, and ultrasonic cleaning with acetone, absolute ethanol and deionized water for 5 minutes each; the ultrasonic power is 200 watts.

[0060] Step 2, preparing electrolyte: the electrolyte is ammonium fluoride electrolyte, silver nitrate electrolyte, saturated potassium chloride electrolyte and sodium sulfate electrolyte. in:

[0061] The ammonium fluoride electrolyte is made up of 0.25wt% ammonium fluoride, 2.5vol% deionized water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tube chief | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com