High-efficiency ternary organic solar cell

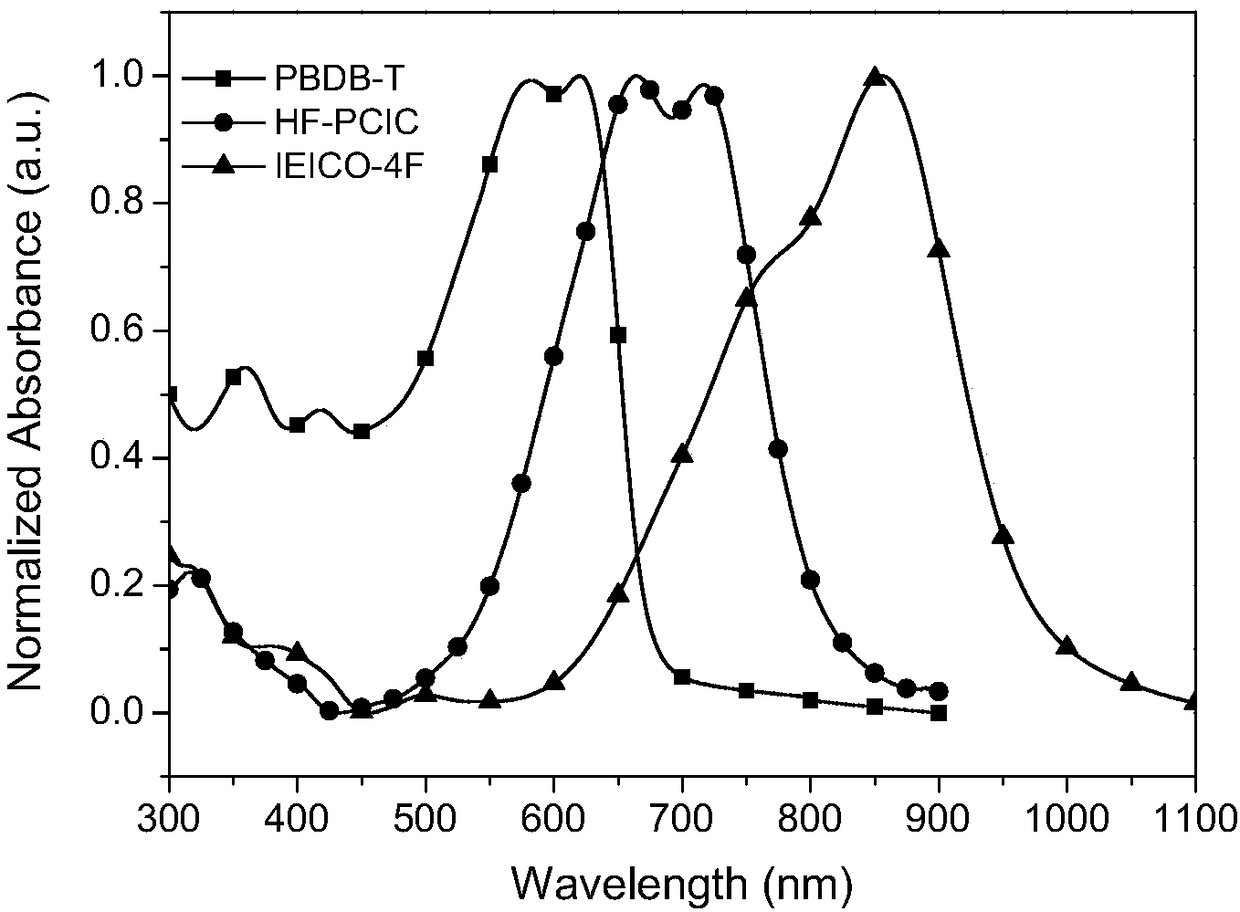

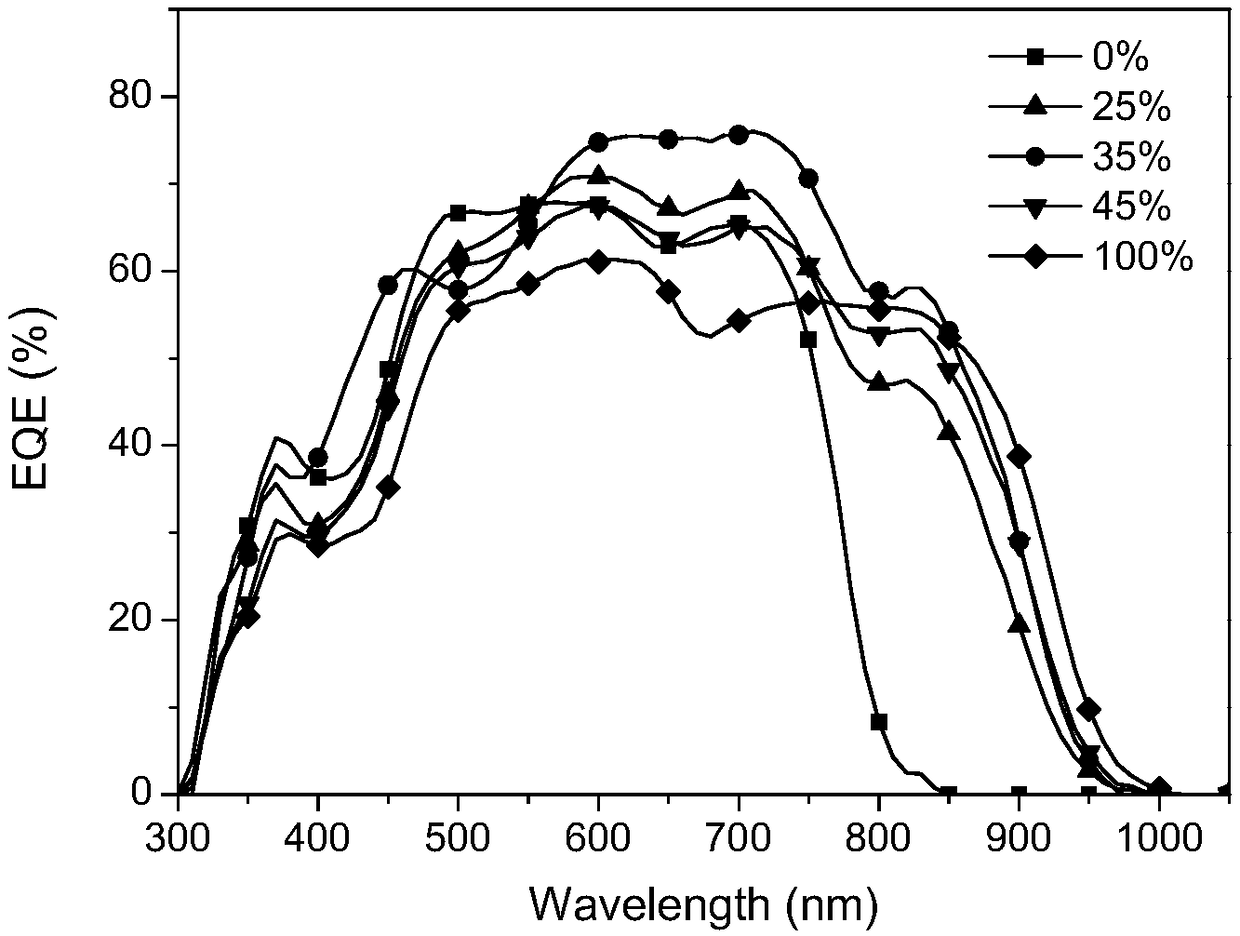

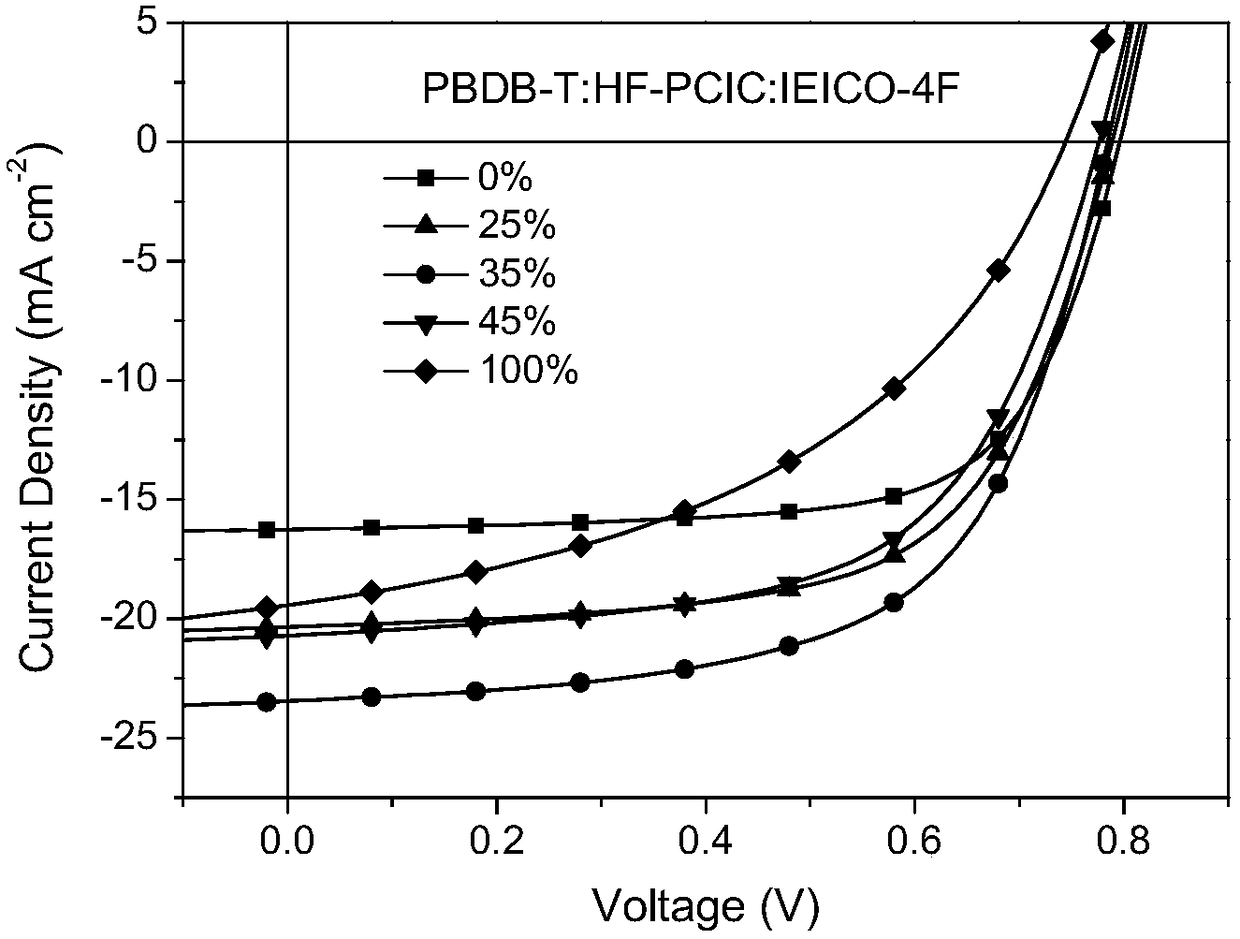

An organic solar cell, high-efficiency technology, applied in the field of solar cells, can solve problems such as damage, limiting the battery short-circuit current density and efficiency improvement, and limiting the efficiency improvement of ternary cells.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The transparent conductive glass with strip-shaped ITO (cathode) etched on the surface was cleaned by ultrasonic oscillation with cleaning agent, deionized water, acetone and isopropanol in turn, dried, and then treated with ultraviolet ozone for 15 minutes; then on the surface of the conductive glass A layer of ZnO was spin-coated at 3500 rpm, the spin-coating time was 60 seconds, and then annealed at 170 °C for 20 minutes. The wafers were then transferred to a glove box, and a layer of PFN was spin-coated on ZnO with a 0.4 mg / mL PFN solution at 3000 rpm for a spin-coating time of 60 s. After that, spin-coat PBDB-T and HF-PCIC with a weight ratio of PBDB-T:HF-PCIC of 1:1 and a total concentration of 20 mg / mL for 60 seconds at a speed of 2000 rpm to obtain a layer of 100 nm thick active layer. Finally, a layer of MoO with a thickness of 10 nm was evaporated with an evaporation apparatus. 3 interface layer and 100nm thick Ag electrode (anode), resulting in an active ar...

Embodiment 2

[0022] The transparent conductive glass with strip-shaped ITO (cathode) etched on the surface was cleaned by ultrasonic oscillation with cleaning agent, deionized water, acetone and isopropanol in turn, dried, and then treated with ultraviolet ozone for 15 minutes; then on the surface of the conductive glass A layer of ZnO was spin-coated at 3500 rpm, the spin-coating time was 60 seconds, and then annealed at 170 °C for 20 minutes. The wafers were then transferred to a glove box, and a layer of PFN was spin-coated on ZnO with a 0.4 mg / mL PFN solution at 3000 rpm for a spin-coating time of 60 s. After that, spin-coat the PBDB-T and HF-PCIC mixture with a weight ratio of PBDB-T:HF-PCIC of 1:1.2 and a total concentration of 20 mg / mL for 60 seconds at a speed of 2000 rpm to obtain a layer of 100 nm thick active layer. Finally, a layer of MoO with a thickness of 10 nm was evaporated with an evaporation apparatus. 3 interface layer and 100nm thick Ag electrode (anode), resulting i...

Embodiment 3

[0025]The transparent conductive glass with strip-shaped ITO (cathode) etched on the surface is cleaned with cleaning agent, deionized water, acetone and isopropanol by ultrasonic oscillation, dried, and then treated with ultraviolet ozone for 15 minutes; A layer of ZnO was spin-coated at 3500 rpm for 60 seconds, and then annealed at 170° C. for 20 minutes. Then the sheet was transferred to a glove box, and a layer of PFN was spin-coated on the ZnO with a 0.4 mg / mL PFN solution at a rotation speed of 3000 rpm and a spin-coating time of 60 seconds. Afterwards, the PBDB-T:HF-PCIC weight ratio of 1:1.5, the total concentration of 20mg / mL of PBDB-T, HF-PCIC mixture, with the speed of 2000rpm, spin coating for 60 seconds, to obtain a layer of 100nm thick active layer. Finally, a layer of MoO with a thickness of 10 nm was evaporated with an evaporation apparatus. 3 interface layer and a 100nm thick Ag electrode (anode), resulting in an effective area of 6mm 2 organic solar cell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com