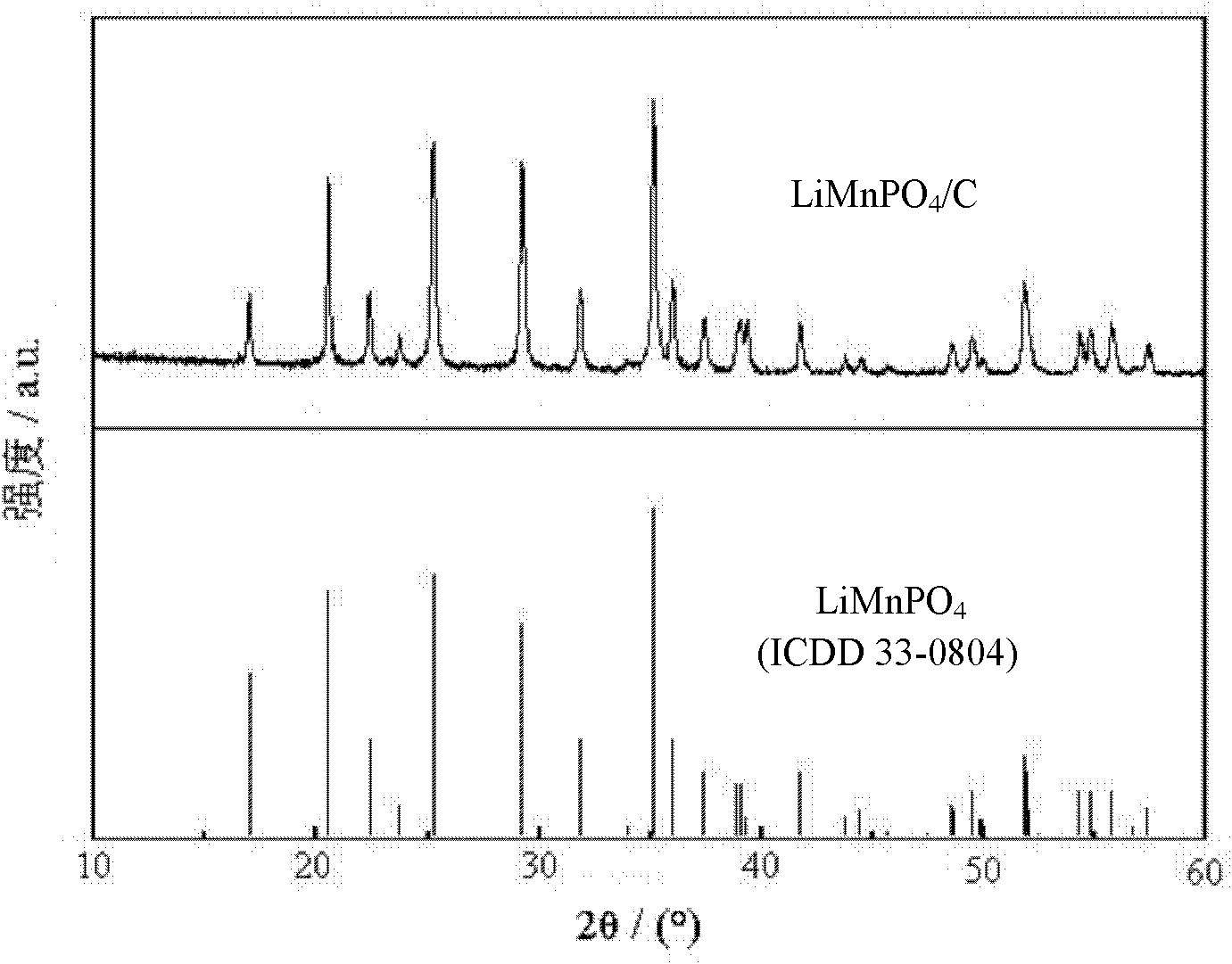

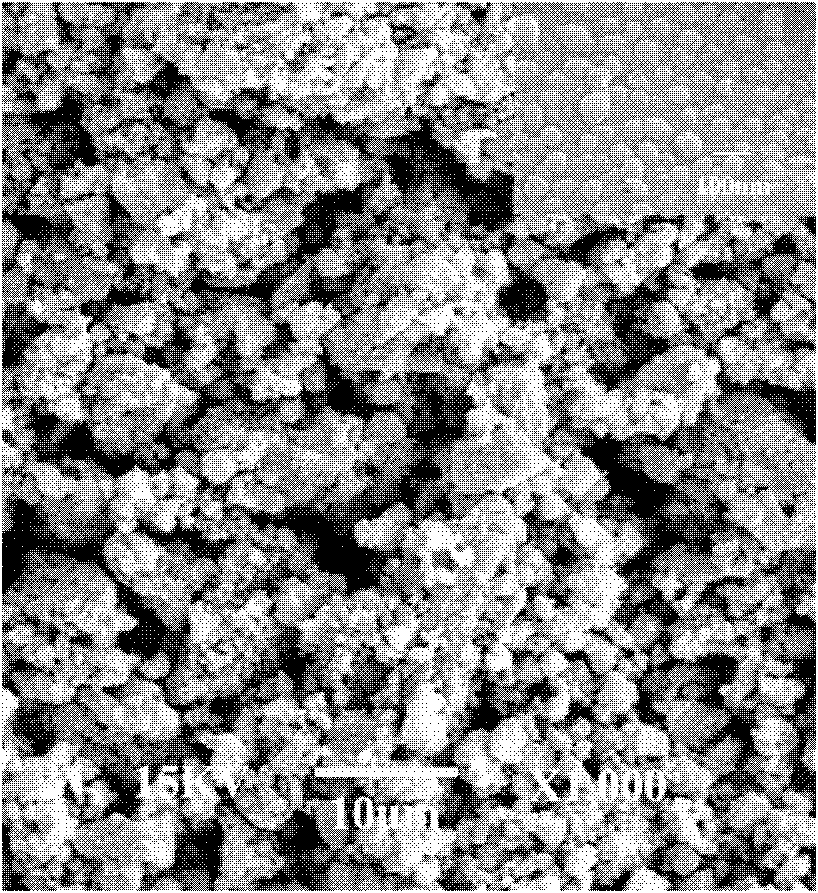

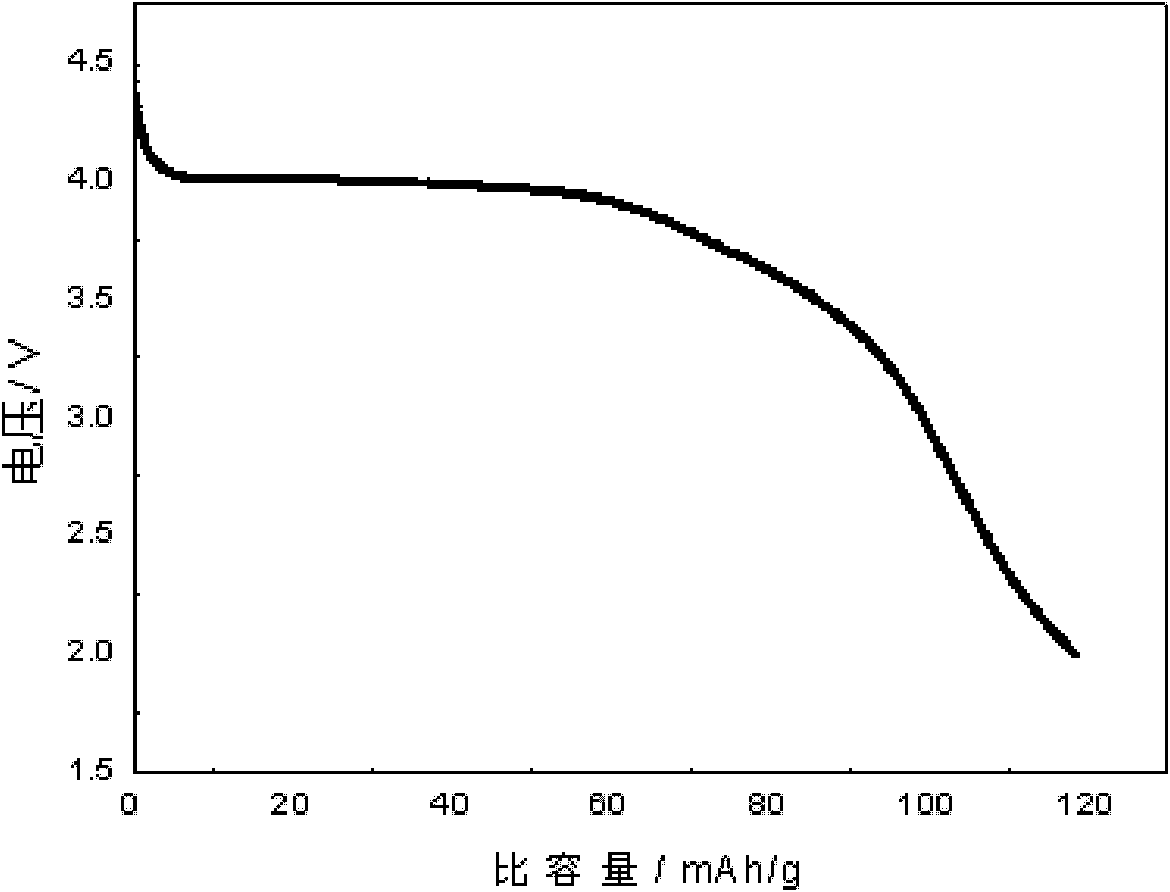

Method for preparing lithium manganese battery material lithium manganese phosphate/carbon by sol-gel

A lithium-ion battery, lithium manganese phosphate technology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problem of low purity of synthetic products, and achieve the effect of excellent electrochemical performance, uniform distribution, and high energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Manganese citrate preparation:

[0025] Using manganese chloride and citric acid as raw materials, dissolve 9.9g of manganese chloride and 21g of citric acid in deionized water, adjust the pH value of the solution to 2.7 with ammonia water, and magnetically stir in a 60°C water bath. After stirring for about 30 minutes, a white precipitate appeared, and the reaction was continued for 5 hours until the solution was completely precipitated, treated with ultrasonic waves for 30 minutes, and filtered with suction to obtain manganese citrate compound.

[0026] 1) Precursor preparation: 0.78g Li 2 CO 3 , 5.26gMn(Hct) 2 , 2.3gH 3 PO 4 , 4.2gH(ct)2(Li:Mn:P:complexing agent=1.025:1:1:1) was dissolved in 100ml deionized water, stirred for 10 minutes, and the test pH value was 3.2, and the sol was obtained by magnetic stirring for a period of time solution, after the sol solution is clarified, place it in a 60°C water bath and evaporate to dryness until a xerogel is obtained;...

Embodiment 2

[0036] 1) Precursor preparation: 0.78g Li 2 CO 3 , 5.26gMn(Hct) 2 , 2.3gH 3 PO 4 , 4.2gH(ct)2(Li:Mn:P:complexing agent=1.025:1:1:1) was dissolved in 100ml deionized water, stirred for 10 minutes, and the test pH value was 3.2, and the sol was obtained by magnetic stirring for a period of time solution, after the sol solution is clarified, place it in a 60°C water bath and evaporate to dryness until a xerogel is obtained;

[0037] 2) Drying treatment: dry the obtained xerogel at 120°C to obtain a dry solid, take it out and grind it to obtain a precursor powder;

[0038] 3) roasting treatment: take a certain amount of the pulverized mixture in the above-mentioned process and put it in the ceramic ark. 2 (where H 2 The volume fraction is 10%), adopting the method of temperature programming, firstly, the mixture is heated to 350°C at a rate of 2°C / min and kept for 5h, then heated to 600°C at a rate of 5°C / min and kept for 3h, and then cooled naturally in the furnace To room...

Embodiment 3

[0041] 1) Precursor preparation: 0.78g Li 2 CO 3 , 5.26gMn(Hct) 2 , 2.3gH 3 PO 4 , 4.2gH(ct)2(Li:Mn:P:complexing agent=1.025:1:1:1) was dissolved in 100ml deionized water, stirred for 10 minutes, and the test pH value was 3.2, and the sol was obtained by magnetic stirring for a period of time solution, after the sol solution is clarified, place it in a 60°C water bath and evaporate to dryness until a xerogel is obtained;

[0042] 2) Drying treatment: dry the obtained xerogel at 120°C to obtain a dry solid, take it out and grind it to obtain a precursor powder;

[0043] 3) roasting treatment: take a certain amount of the pulverized mixture in the above-mentioned process and put it in the ceramic ark. 2 (where H 2 The volume fraction is 10%), using a temperature program method, firstly the mixture is heated to 350°C at a rate of 2°C / min and kept for 5h, then heated to 500°C at a rate of 5°C / min and kept for 3h, and then cooled naturally in the furnace To room temperature,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com