A preparation method of cerium oxide nanoparticles and its anti-oxidation application

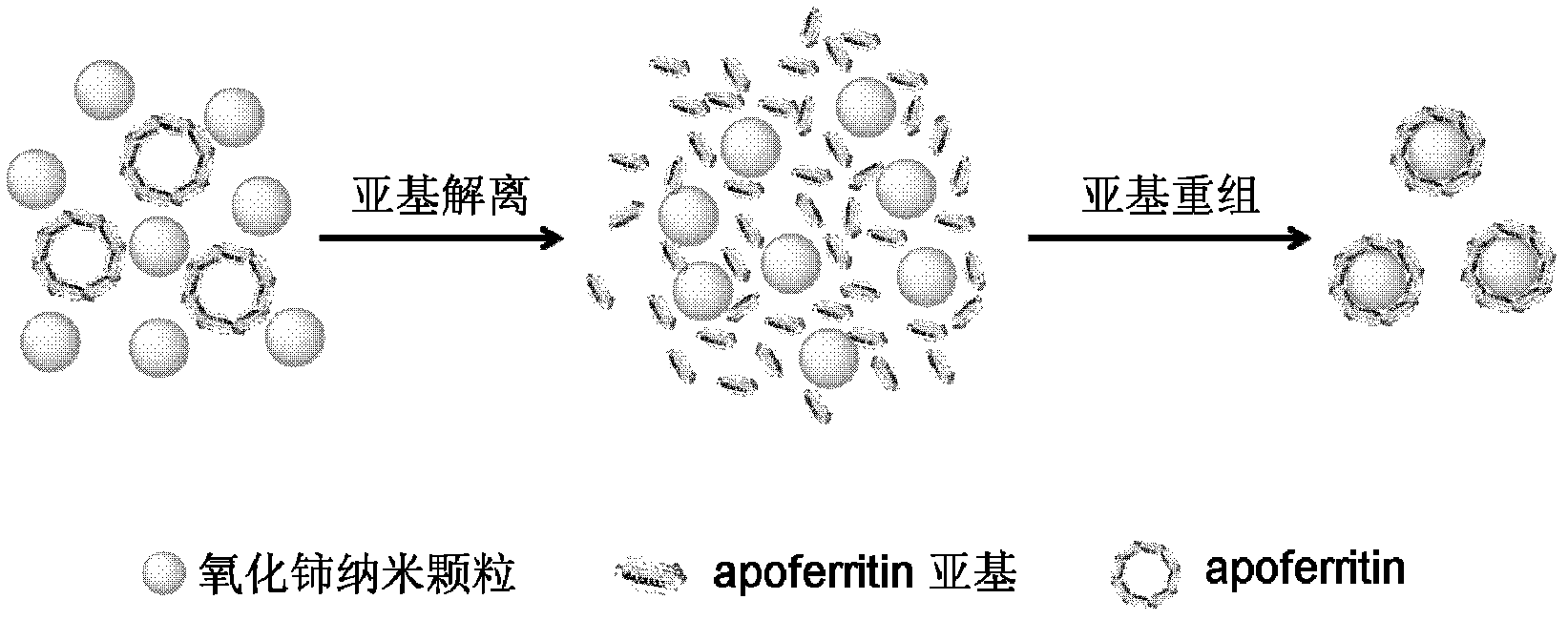

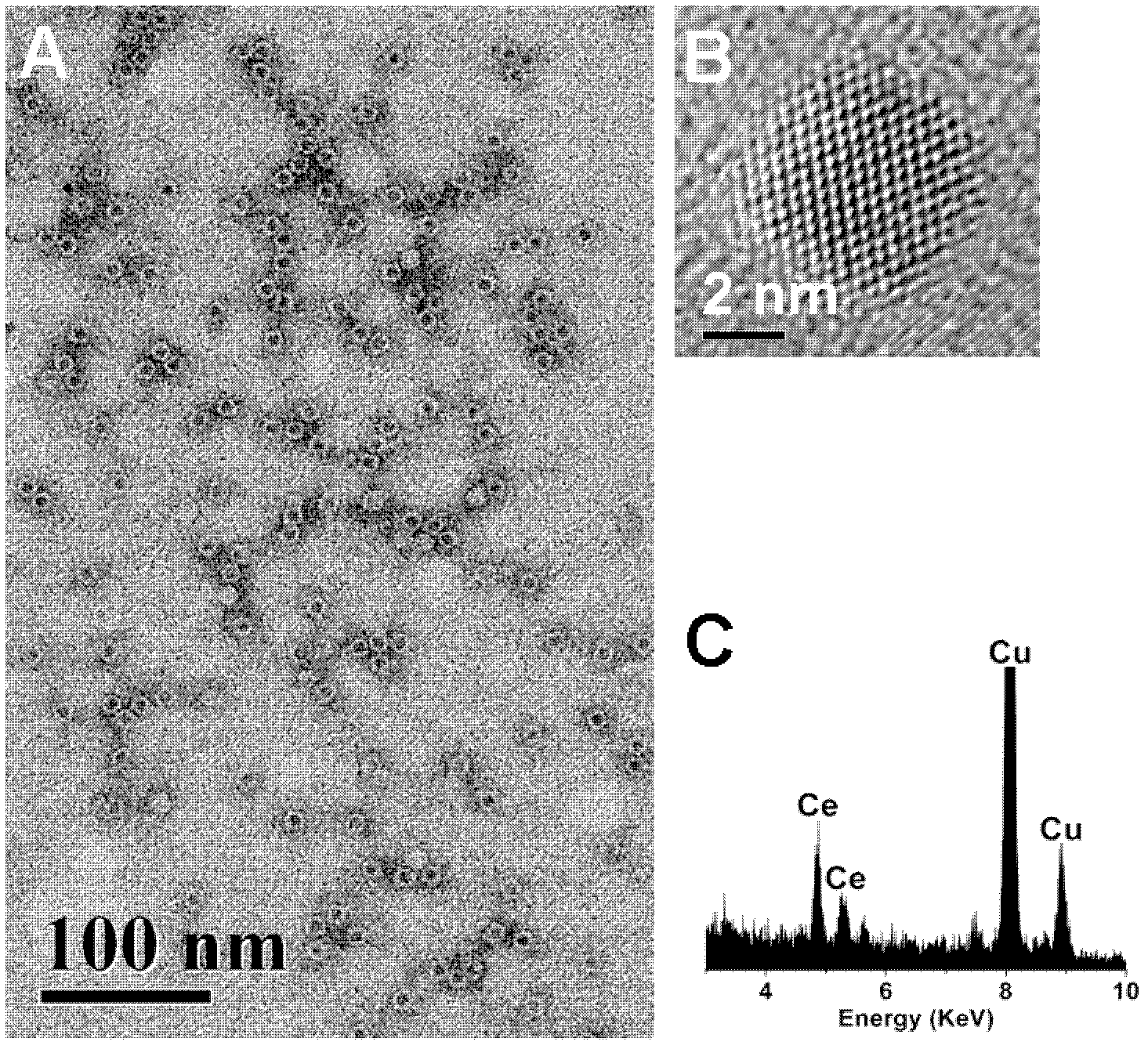

A technology of nanoparticles and cerium oxide, which is applied in the field of preparation of cerium oxide nanoparticles, can solve the problems such as biosafety can not be ignored, and achieve the effect of superior antioxidant activity and improvement of free radical scavenging activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

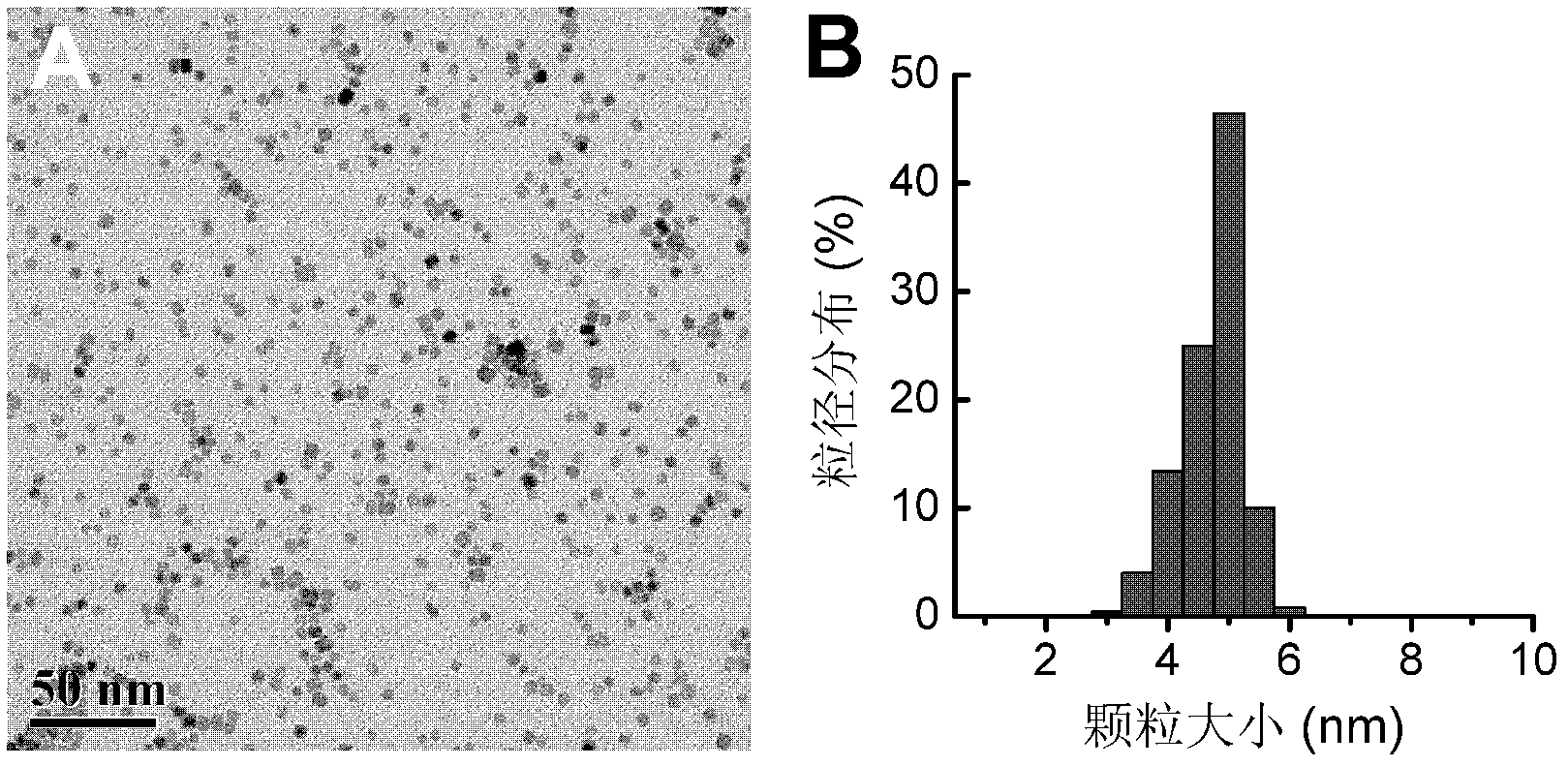

[0027] Embodiment 1. Preparation of cerium oxide nanoparticles with uniform particle size by hydrothermal method.

[0028] Weigh 2.74g (NH 4 ) 2 Ce(NO 3 ) 6 and 10g CH 3 COONa was dissolved in 70ml of deionized water, then 10ml of glacial acetic acid was added to the solution, and stirred at room temperature for 1h. After that, the mixed solution was transferred to a polytetrafluoroethylene liner, sealed with a stainless steel hydrothermal kettle, and heated in an oven at 220° C. for 12 hours. Finally, the obtained yellow precipitate was centrifuged (6000 g, 10 min), washed with deionized water and ethanol several times, and then dried in an oven at 60° C. overnight.

Embodiment 2

[0029] Example 2. Preparation of cerium oxide nanoparticles with uniform particle size by hydrothermal method.

[0030] Weigh 5.48g (NH 4) 2 Ce(NO 3 ) 6 and 20g CH 3 COONa was dissolved in 140ml of deionized water, then 20ml of glacial acetic acid was added to the solution, and stirred at room temperature for 1h. After that, the mixed solution was transferred to a polytetrafluoroethylene liner, sealed with a stainless steel hydrothermal kettle, and heated in an oven at 220° C. for 12 hours. Finally, the obtained yellow precipitate was centrifuged (10000 g, 20 min), washed with deionized water and ethanol several times, and then dried overnight in an oven at 60°C.

Embodiment 3

[0031] Example 3. Preparation of cerium oxide nanoparticles with uniform particle size by hydrothermal method.

[0032] Weigh 1.63g Ce(NO 3 ) 3 and 10g CH 3 COONa was dissolved in 70ml of deionized water, then 10ml of glacial acetic acid was added to the solution, and stirred at room temperature for 1h. After that, the mixed solution was transferred to a polytetrafluoroethylene liner, sealed with a stainless steel hydrothermal kettle, and heated in an oven at 220° C. for 24 hours. Finally, the obtained precipitate was centrifuged (10000 g, 20 min), washed with deionized water and ethanol several times, and then dried overnight in an oven at 60°C.

[0033] In the above experiments, Ce(NO 3 ) 3 Other inorganic cerium salts can also be used instead.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com