Pressure-resistant and high-power emulsified seismic source grain and preparation method thereof

A technology of seismic source charge and power, which is applied in the direction of explosives, etc., can solve the problems of unfavorable automatic charge machine charging, reduced explosive performance, poor fluidity, etc., and achieve the effect of improving work efficiency, low viscosity, and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

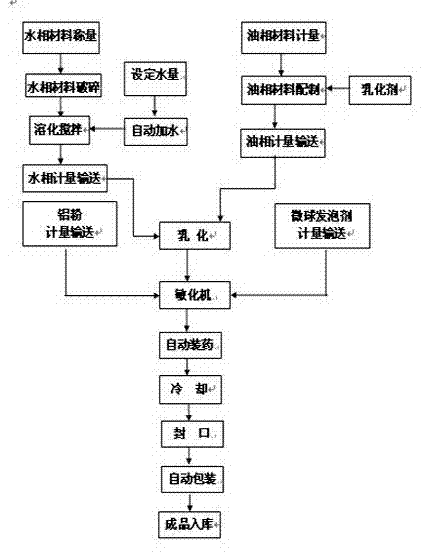

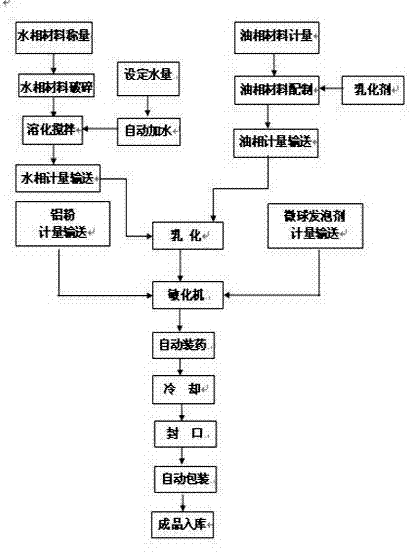

Method used

Image

Examples

Embodiment Construction

[0024] Add 50kg of water to the water phase tank automatically and quantitatively through the flow meter. When the water temperature rises to 65°C, add 800kg of crushed ammonium nitrate, 50kg of sodium nitrate, crystal form modifier (potassium nitrate, potassium sulfate, potassium chloride) , Potassium carbonate, Potassium thiocyanate, Potassium fluoride, Potassium chromate, or a mixture of two or more of the above-mentioned potassium salts) 60kg into the water phase tank, start stirring at the same time, continue heating to 100-120 ℃, heat preservation for later use; add 50kg of composite wax into the oil phase melting tank, and when the temperature of the oil phase reaches 60-80°C, add 15kg of emulsifier (ester or / and amide emulsifier), stir evenly, and continue heating to temperature to 100-120°C, keep warm for later use; pass the prepared oil and water phase solutions through their respective filters and metering pumps, and continuously enter the emulsifier for emulsificati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com