A kind of Lactococcus lactis and the antibacterial peptide produced by the Lactococcus lactis and the application of the antibacterial peptide

A technology of Lactococcus lactis and antimicrobial peptides, applied in the field of antimicrobial peptides, can solve problems such as poor stability, low solubility, and affecting the application of Nisin, and achieve stable antibacterial and significant bactericidal effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Lactococcus lactis LLC518 of the present invention is obtained in the following manner:

[0042]1. Wash and cut fresh cucumbers purchased from the market in Hefei, Anhui, into small pieces, fill a 50ml sterile test tube, compact it, seal it with plastic skin and kraft paper, and enrich it at 30°C for 48 hours, then take a sample and spread it on MRS selection medium containing 0.01% bromocresol purple.

[0043] 2. Pick the acid-producing strains that make the MRS selection medium containing 0.01% bromocresol purple turn yellow, and further isolate and purify them;

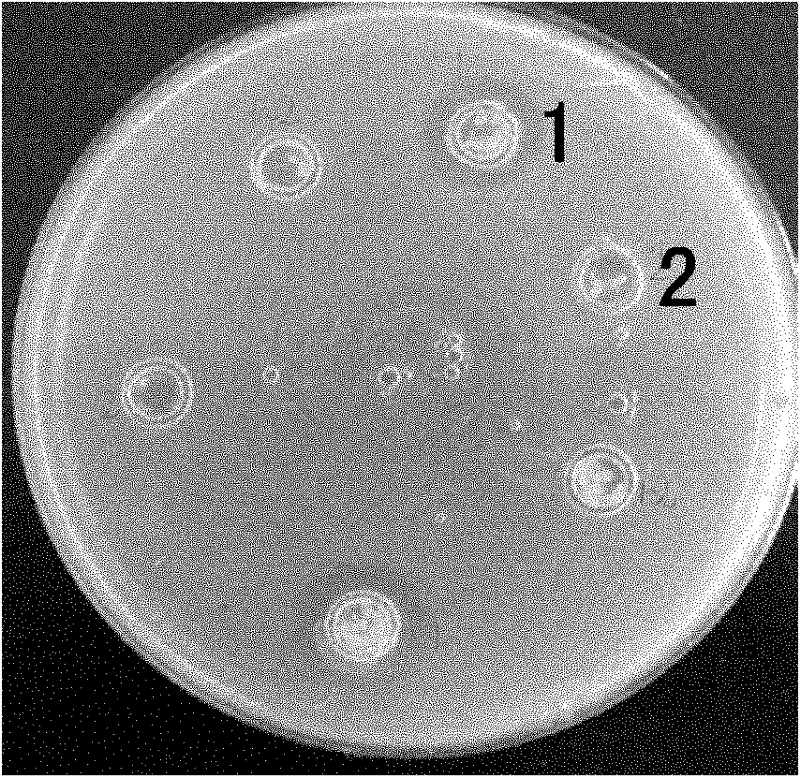

[0044] 2. Using Lactobacillus sp. LSX801 as an indicator bacterium, the bacterial strain with antibacterial ability was obtained by plate spotting method;

[0045] 3. Obtain the fermented liquid through fermentation, centrifuge to obtain the supernatant, filter through a 0.45 μm filter membrane to remove the bacteria, add 40% ammonium sulfate to treat the filtrate, dialyze and freeze-dry to make crude prote...

Embodiment 2

[0056] The preparation steps of antibacterial peptide are as follows:

[0057] A. Fermentation of antimicrobial peptides: Pick activated Lactococcus lactis subsp.lactis LLC518CGMCC No.4584 from the MRS slant medium and inoculate it in the MRS seed medium, cultivate it on a shaker at 28°C for 12 hours, and then inoculate The seed liquid is inoculated in the MRS fermentation medium according to the inoculation amount of 4%, and cultured at 28°C for 24 hours to obtain the fermentation liquid;

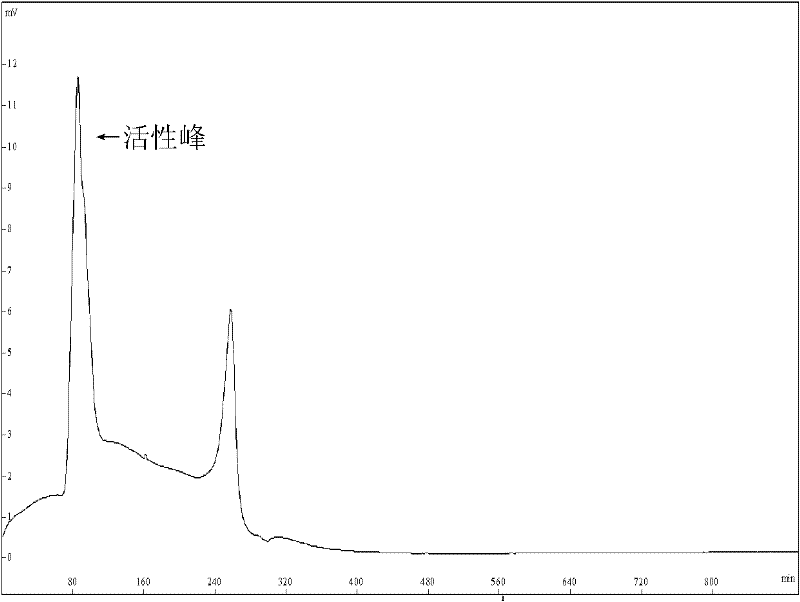

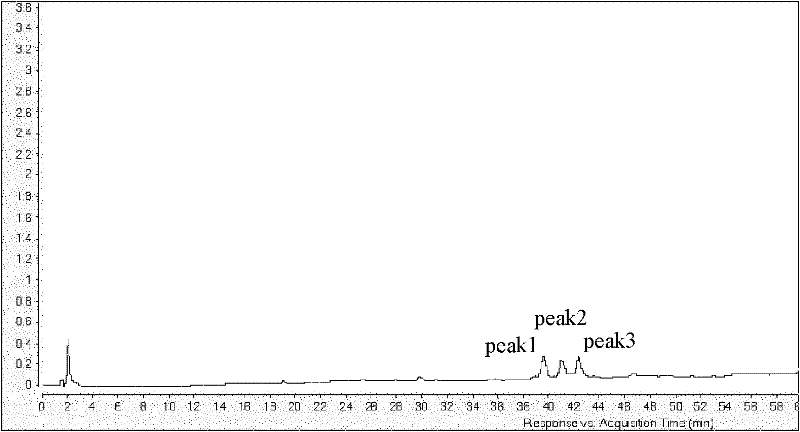

[0058] B. Separation and purification of antimicrobial peptides: centrifuge the fermented liquid at 4°C and 8000r / min for 25min, take the supernatant and filter it through a filter membrane with a pore size of 0.45μm, and the obtained filtrate is subjected to sulfuric acid at a saturation of 30-50%. Ammonium precipitation, after 12 hours, centrifuge at 4°C, 8000r / min for 45min to obtain the precipitated protein, dissolve the precipitated protein in water and dialyze for 4h in a dialysis ba...

Embodiment 3

[0064] The preparation steps of antibacterial peptide are as follows:

[0065] A. Fermentation of antimicrobial peptides: Pick activated Lactococcus lactis subsp.lactis LLC518CGMCC No.4584 from the MRS slant medium and inoculate it in the MRS seed medium, cultivate it on a shaker at 28°C for 12 hours, and then inoculate The seed liquid is inoculated in the MRS fermentation medium according to the inoculation amount of 4%, and cultured at 28°C for 24 hours to obtain the fermentation liquid;

[0066] B. Under the condition of temperature of 25°C, the fermentation liquid is filtered through a ceramic membrane with an operating pressure of 0.02Mpa and a membrane pore size of 0.2 μm to obtain a filtrate, and solid salt is added to the filtrate. The volume percentage is 5-20%. After the solid table salt is completely dissolved, it is spray-dried. The air inlet temperature of the spray dryer is 130-150°C, and the outlet air temperature is 110-130°C.

[0067] The effect of the mass r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com